UV Curing System Market Size, Growth, Global Trends, Forecast 2034

UV Curing System Market By Technology Type (UV LED Systems, Mercury Arc Lamp Systems, Xenon Arc Lamp Systems, and Fluorescent Lamp Systems), By Application (Printing and Coating, Electronics Manufacturing, Automotive Components, and Medical Device Production), By Distribution Channel (Direct Sales, Authorized Distributors, Online Platforms, and Technical Service Providers), By End-User (Manufacturing Companies, Printing Industries, Electronics Manufacturers, and Research Institutions), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

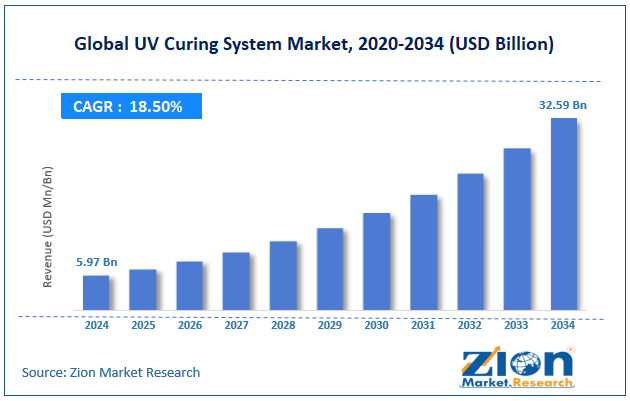

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 5.97 Billion | USD 32.59 Billion | 18.50% | 2024 |

UV Curing System Industry Perspective:

The global UV curing system market was valued at approximately USD 5.97 billion in 2024 and is expected to reach around USD 32.59 billion by 2034, growing at a compound annual growth rate (CAGR) of roughly 18.50% between 2025 and 2034.

Key Insights:

- As per the analysis shared by our research analyst, the global UV curing system market is estimated to grow annually at a CAGR of around 18.50% over the forecast period (2025-2034)

- In terms of revenue, the global UV curing system market size was valued at around USD 5.97 billion in 2024 and is projected to reach USD 32.59 billion by 2034.

- The UV curing system market is projected to grow significantly due to the increasing adoption of energy-efficient manufacturing processes and expanding applications in electronics and the automotive industries.

- Based on technology type, UV LED systems lead the segment and will continue to dominate the global market.

- Based on application, printing and coating are expected to lead the market.

- Based on the distribution channel, direct sales are anticipated to command the largest market share.

- Based on end-users, manufacturing companies are expected to lead the market during the forecast period.

- Based on region, North America is projected to lead the global market during the forecast period.

UV Curing System Market: Overview

Ultraviolet (UV) curing systems are modern industrial tools that use ultraviolet light to quickly cure or dry coatings, adhesives, inks, and other materials through a process called photo polymerization. These systems operate more efficiently, consume less energy, and produce higher-quality results than traditional heat-based curing methods. The UV curing system market includes LED systems that allow precise control of light, mercury arc lamp systems for strong curing needs, and special machines for different industrial uses. Modern UV curing systems come with better cooling, automated controls, and safety features to ensure reliable performance and protect workers from UV light. The industry continues to innovate with new lamp designs, better energy use, and smart integration into automated systems to improve efficiency and reduce environmental harm.

The increasing demand for environmentally friendly manufacturing processes and the growing adoption of UV-curable materials are expected to drive substantial growth in the UV curing system market over the forecast period.

UV Curing System Market Dynamics

Growth Drivers

Environmental regulations and sustainability initiatives

The UV curing system market is growing fast as industries look for eco-friendly alternatives to older solvent-based curing methods, which release harmful gases and need large ventilation systems. Strict environmental rules around the world are pushing companies to switch to UV curing, as it cuts down on emissions, uses less energy, and creates less waste. As businesses try to follow green practices, more of them are choosing UV curing systems that support clean chemistry and help meet their environmental goals. Company sustainability plans and government rules are pushing industries to use UV curing systems to reduce environmental harm while keeping their product quality high.

Technological advancements and energy efficiency improvements

The UV curing system market is moving fast with advances in LED technology, lamp design, and control systems, making it more energy-efficient and productive. Modern UV LED systems have longer lifespans, instant on-off capabilities, and precise wavelength control, which can save up to 70% of energy compared to traditional mercury arc lamps. Advanced cooling systems, automated intensity control, and intelligent monitoring are making the system more reliable and reducing maintenance and operational costs. Integration with Industry 4.0 technologies like remote monitoring, predictive maintenance, and data analytics is helping manufacturers optimize the UV curing process and enhance overall equipment effectiveness.

Restraints

High initial capital investment and equipment costs

Despite the long-term operational benefits, the UV curing system industry faces challenges with the high upfront capital required for high-end UV curing equipment, especially for LED and specialized applications. UV curing systems can be much more expensive than thermal curing equipment, so small to medium-sized manufacturers with limited budgets can’t afford them. Additional costs for facility modifications, safety equipment, and operator training can add to the total cost of ownership for UV curing systems. Choosing the right UV curing system for your application can be technical and requires consultation services that add to the overall cost.

Opportunities

Expanding electronics and automotive applications

The UV curing system market has plenty of growth opportunities in electronics manufacturing, automotive components, and emerging technologies that require precise and fast curing. The demand for miniaturized electronics, flexible electronics, and advanced automotive components is driving the need for UV curing systems that can process heat-sensitive materials without thermal damage. Electric vehicle production is creating new opportunities for UV curing in battery components, electronic systems, and lightweight composite materials that require specialized curing. Smart devices, wearables, and Internet of Things applications are expanding the market for UV curing systems that can process new materials and complex geometries.

Challenges

Technical complexity and application-specific requirements

The UV curing system market faces challenges related to the technical complexity of matching UV curing parameters with specific material formulations, substrate characteristics, and production requirements. Different UV curable materials require specific wavelength combinations, intensity levels, and exposure times that need to be calibrated to achieve optimal curing without material degradation or production defects. The need for technical knowledge and application expertise can hinder the adoption of UV curing in industries with less photo polymerization experience. Maintaining curing quality across different production batches, environmental conditions, and equipment variations requires complex control systems and regular calibration.

UV Curing System Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | UV Curing System Market |

| Market Size in 2024 | USD 5.97 Billion |

| Market Forecast in 2034 | USD 32.59 Billion |

| Growth Rate | CAGR of 18.50% |

| Number of Pages | 213 |

| Key Companies Covered | Phoseon Technology, Heraeus Noblelight GmbH, Nordson Corporation, Dymax Corporation, Panasonic Corporation, Hönle AG, Baldwin Technology Company Inc., IST METZ GmbH, Fusion UV Systems Inc., American Ultraviolet Company, Xenon Corporation, Polytec GmbH, Miltec UV International LLC, Uvitron International Inc., Integration Technology Ltd., and others. |

| Segments Covered | By Technology Type, By Application, By Distribution Channel, By End User, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

UV Curing System Market: Segmentation

The global UV curing system market is segmented into technology type, application, distribution channel, end-user, and region.

Based on technology type, the market is segregated into UV LED systems, mercury arc lamp systems, xenon arc lamp systems, and fluorescent lamp systems. UV LED systems lead the market due to their superior energy efficiency, longer operational lifespan, instant on-off capabilities, and precise wavelength control, which provides optimal curing performance for various applications.

Based on application, the UV curing system industry is classified into printing and coating, electronics manufacturing, automotive components, and medical device production. Printing and coating hold the largest market share due to widespread adoption of UV-curable inks, coatings, and adhesives in commercial printing, packaging, and industrial coating applications.

Based on the distribution channel, the UV curing system market is divided into direct sales, authorized distributors, online platforms, and technical service providers. Direct sales are expected to lead the market during the forecast period due to the technical complexity of UV curing systems and the need for customized solutions, technical support, and ongoing service relationships.

Based on the end-user, the market is segmented into manufacturing companies, printing industries, electronics manufacturers, and research institutions. Manufacturing companies lead the market share due to widespread adoption of UV curing technology across various industrial sectors seeking to improve production efficiency, reduce environmental impact, and enhance product quality.

UV Curing System Market: Regional Analysis

North America to lead the market

North America is the largest UV curing system market due to its advanced manufacturing capabilities, strong support for green technologies, and significant research and development investment. It accounts for approximately 40% of the global market, with the US being the largest user of UV technology in printing, electronics, and automotive industries.

North American manufacturers are at the forefront of innovative UV curing applications, including advanced LED systems, specialty coatings, and automated curing processes that have set the industry standard worldwide. They have strong technical expertise, established supply chains, and relationships between equipment manufacturers, material suppliers, and end-users that drive innovation in UV curing. Continuous innovation in smart manufacturing and Industry 4.0 integration is further boosting the region’s leadership in the UV curing space. Strategic partnerships between industry leaders and research institutions are accelerating the development of next-generation UV technologies.

Europe is expected to demonstrate strong growth.

Europe is experiencing robust growth in the UV curing system market as the region's strict environmental regulations, sustainability initiatives, and advanced manufacturing capabilities create favorable conditions for UV curing technology adoption. European manufacturers are investing in UV curing systems to meet volatile organic compound emission regulations and stay competitive.

The region’s strong automotive, electronics, and packaging industries are driving demand for advanced UV curing solutions for high-end manufacturing. Government incentives for clean tech and increasing awareness of the environmental benefits are driving the move from traditional thermal curing to UV curing across all industries. Collaborative efforts among governments, the private sector, and academic institutions are supporting a sustainable and innovation-driven growth model for the market.

Recent Market Developments:

- In June 2025, Phoseon Technology launched a revolutionary UV LED curing system with adjustable wavelength capabilities, enabling manufacturers to optimize curing processes for different material formulations without changing equipment.

- In April 2025, Heraeus Noblelight introduced an energy-efficient mercury arc lamp system with advanced cooling technology, reducing energy consumption by 30% while maintaining high-intensity UV output for industrial applications.

UV Curing System Market: Competitive Analysis

The global UV curing system market is led by players like:

- Phoseon Technology

- Heraeus Noblelight GmbH

- Nordson Corporation

- Dymax Corporation

- Panasonic Corporation

- Hönle AG

- Baldwin Technology Company Inc.

- IST METZ GmbH

- Fusion UV Systems Inc.

- American Ultraviolet Company

- Xenon Corporation

- Polytec GmbH

- Miltec UV International LLC

- Uvitron International Inc.

- Integration Technology Ltd.

The global UV curing system market is segmented as follows:

By Technology Type

- UV LED Systems

- Mercury Arc Lamp Systems

- Xenon Arc Lamp Systems

- Fluorescent Lamp Systems

By Application

- Printing and Coating

- Electronics Manufacturing

- Automotive Components

- Medical Device Production

By Distribution Channel

- Direct Sales

- Authorized Distributors

- Online Platforms

- Technical Service Providers

By End User

- Manufacturing Companies

- Printing Industries

- Electronics Manufacturers

- Research Institutions

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

An Ultra Violet (UV) curing system is a modern industrial tools that use ultraviolet light to quickly cure or dry coatings, adhesives, inks, and other materials through a process called photo polymerization.

The UV curing system market is expected to be driven by increasing environmental regulations, growing demand for energy-efficient manufacturing processes, technological advancements in LED systems, expanding applications in electronics and automotive industries, and rising adoption of sustainable manufacturing practices.

According to our study, the global UV curing system market was worth around USD 5.97 billion in 2024 and is predicted to grow to around USD 32.59 billion by 2034.

The CAGR value of the UV curing system market is expected to be around 18.50% during 2025-2034.

The global UV curing system market will register the highest revenue contribution from North America during the forecast period.

Key players in the UV curing system market include Phoseon Technology, Heraeus Noblelight GmbH, Nordson Corporation, Dymax Corporation, Panasonic Corporation, Hönle AG, Baldwin Technology Company Inc., IST METZ GmbH, Fusion UV Systems Inc., American Ultraviolet Company, Xenon Corporation, Polytec GmbH, Miltec UV International LLC, Uvitron International Inc., and Integration Technology Ltd.

The report provides a comprehensive analysis of the UV curing system market, including an in-depth examination of market drivers, restraints, emerging trends, regional dynamics, and future growth prospects. It also examines the competitive dynamics, technology innovations, distribution strategies, and customer preferences that shape the modern industrial equipment and technology ecosystem.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed