Composite Materials Market Size, Share Report, Analysis, Trends, Growth 2032

Composite Materials Market By Fiber Type (Glass Fiber Composites, Carbon Fiber Composites, Natural Fiber Composites and Other Fiber Composites) By Resin Type (Thermoset Composites and Thermoplastic Composites), By Manufacturing Process (Layup Process, Filament Winding Process, Injection Molding Process, Pultrusion Process, Compression Molding Process, Resin Transfer Molding Process and Others), By End-User Industry (Aerospace & Defense, Wind Energy, Automotive & Transportation, Construction & Infrastructure, Marine, Pipes & Tanks, Electrical & Electronics and Others): Global Industry Perspective, Comprehensive Analysis and Forecast, 2024 - 2032-

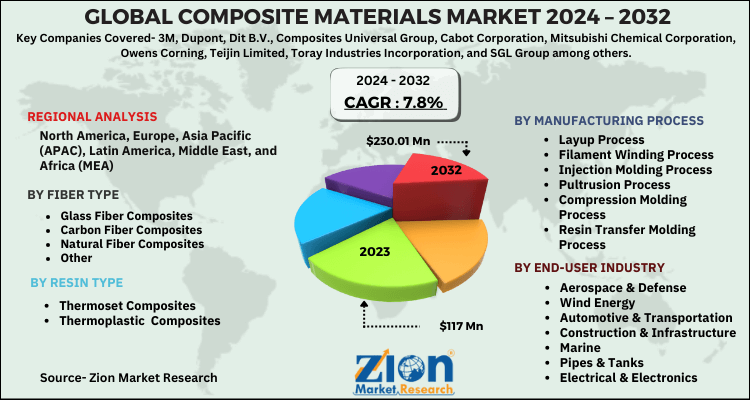

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 117 Million | USD 230.01 Million | 7.8% | 2023 |

Composite Materials Market Insights

Zion Market Research has published a report on the global Composite Materials Market, estimating its value at USD 117 Million in 2023, with projections indicating that it will reach USD 230.01 Million by 2032. The market is expected to expand at a compound annual growth rate (CAGR) of 7.8% over the forecast period 2024-2032. The report explores the factors fueling market growth, the hitches that could hamper this expansion, and the opportunities that may arise in the Composite Materials industry. Additionally, it offers a detailed analysis of how these elements will affect market demand dynamics and market performance throughout the forecast period.

Materials that are formed by the combination more than two materials with different properties, without blending or dissolving them into each other are called composite material. Some examples of composite include mud bricks, fiberglass, and concrete. Most of these composites material are made by taking one material and having it surround fragments of a stronger material. Currently, the aerospace and defense industry is facing a supply-demand crunch, due to the huge order backlog and orders placed in the past, which is expected to propel the production in the industry, due to the uplifting of lockdown in phases.

Composite Materials Market: COVID-19 Impact Analysis

COVID-19 has negatively impacted the demand and supply for composites material across numerous end-use industry which includes automotive & transportation, aerospace & defense, wind energy, pipes & tanks, and construction & infrastructure. The restriction in the movement of goods and services resulted in non-arrival or delay of raw materials, disruption in the financial flows along with surging no-showsamong production line workers have forced aircraft and manufacturers to operate at partial or zero capacities. This has led to condensed demand for composites.

Composite Materials Market: Growth Factors

The composite materials market is anticipated to witness growth in the estimated timeframe. This surge is due to the rising demand for carbon fibers among end-user applications, especially in aerospace & defense applications. In the past few years the automotive segment has become progressively obsessive with consumption of carbon fiber.

The rising use of carbon fiber in the automotive sector is due to the factors related to the reduction of carbon footprint, e-mobility and lightweight construction. The growth in the demand for the composite material is also due to the surging fuel price, which has triggered the demand for electric vehicles.

These materials are widely used as an alternative to wood, aluminum and steel owing to its strength to weight ratio. Raw materials that are required to manufacture composites material include silicone, polyurethane and polyamide among others. These products are also used in other applications such as coatings, construction, adhesives and others. The large number of raw material suppliers is expected to influence market growth in the long run.

Fiber Type Segment Analysis Preview

Glass fiber under fiber type is expected to dominant the fiber type segment and is accounted for a share above 60% in 2024. This surge is due to the high demand in of glass fiber in construction, electrical and electronics, wind energy and transportation industries. It is high in demand due to their low cost and superior mechanical and physical properties such as durability, strength, stability, lightweight and flexibility. These fibers are mostly used in pipes & tanks, wind energy, construction & infrastructure and electrical & electronics. The demand glass fibs has seen slow growth in above mentioned industries due to pandemic, but will gain traction with the recovery in end-use industry.

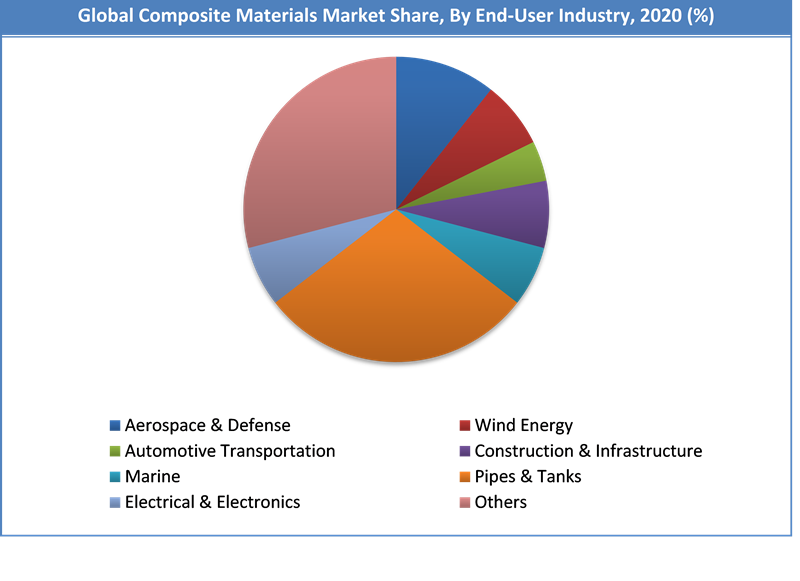

End-User Industry Segment Analysis Preview

Automotive & transportation under the end-user industry segment will grow at a CAGR of over 5.3% from 2024 to 2032. The surge is due to the surging demand is due to the strength-to-weight ratio it offers. Its lightweight with a given strength as compared to wood, aluminum and other materials makes the use of composites vital for the transportation industry. The changing environmental regulations and standards in order to reduce carbon emissions, specifically in Europe, North America, and China, are some of the major factors responsible for the introduction of lightweight and fuel-efficient composites. Due to the pandemic, automobile manufacturers and component suppliers across regions were struggling to continue production after the closure of manufacturing plants in many countries. However, with the rise in travel after the uplifting of the lockdown and the use of private cars for commuting will fuel automotive demand for composites post-pandemic.

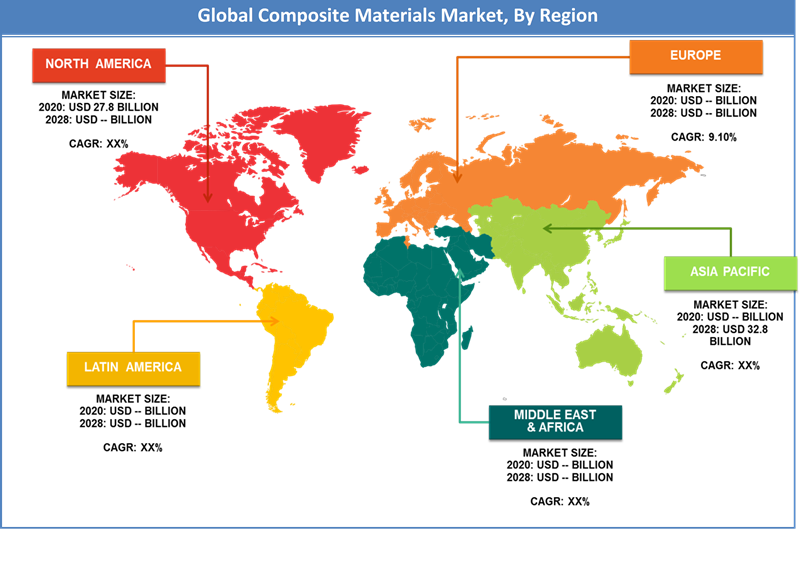

Composite Materials Market: Regional Analysis Preview

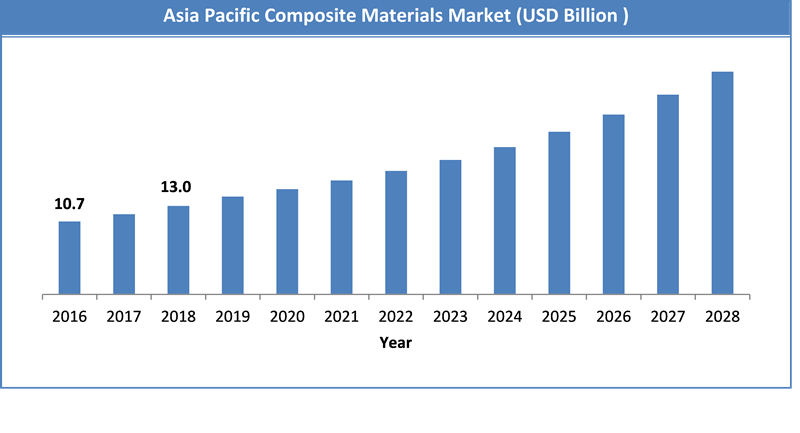

Asia Pacific held a share above 20% in the composite materials market in 2019. This is due to the surging demand of composite material among numerous end-use industries in major economies of Asia Pacific like Japan, India, and China. The emergence of major shipbuilding centers in the Asia Pacific in Indonesia, Philippines, Malaysia, Vietnam, and Singapore is also anticipated to fuel the demand for composites in the Asia Pacific region over the projected period.

With surging investment in construction activities in India and China, the demand for composite materials is projected to surge in the estimated time period. Additionally, the rise in household income coupled with the people migrating from to urban areas along with the increase in the standard of living in anticipated to drive the demand for the residential construction sector in the country, eventually propelling the demand for composite material in the long run.

Composite Materials Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Composite Materials Market |

| Market Size in 2023 | USD 117 Million |

| Market Forecast in 2032 | USD 230.01 Million |

| Growth Rate | CAGR of 7.8% |

| Number of Pages | 185 |

| Key Companies Covered | 3M, Dupont, Dit B.V., Composites Universal Group, Cabot Corporation, Mitsubishi Chemical Corporation, Owens Corning, Teijin Limited, Toray Industries Incorporation, and SGL Group among others. |

| Segments Covered | By Product Type, By Application, And By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

To know more about this report, request a sample copy.

North America is expected to grow at a CAGR of over 7% in 2021-2028. The surge is due to the robust growth of electrical and electronics, aerospace and defense and automotive industries. The U.S. is the manufacturer of large passenger aircraft, commercial aircraft, defense aircraft and cargo jets which is estimated to fuel the market growth in the estimated period. The aerospace and defense industry is vital to the composite market. These materials are utilized in the interior and exterior parts of military aircraft, commercial aircraft, business jets, general aviation aircraft and spacecraft owing to their properties such as safety, lightweight, aerodynamic performance, high reliability, all-weather operation and stealth, which is expected to boost the demand for composite material in the region.

Key Market Players & Competitive Landscape

Some of the key players of composite materials market are

- 3M

- Dupont

- Dit B.V.

- Composites Universal Group

- Cabot Corporation

- Mitsubishi Chemical Corporation

- Owens Corning

- Teijin Limited

- Toray Industries Incorporation

- SGL Group

- among others.

Market players are Indulge in various initiatives like research and development, technology innovations, merger & acquisitions and partnerships to manufacture lightweight and cost-effective composite products.

The global composite materials market is segmented as follows:

By Fiber Type

- Glass Fiber Composites

- Carbon Fiber Composites

- Natural Fiber Composites

- Other

By Resin Type

- Thermoset Composites

- Thermoplastic Composites

By Manufacturing Process

- Layup Process

- Filament Winding Process

- Injection Molding Process

- Pultrusion Process

- Compression Molding Process

- Resin Transfer Molding Process

- Others

By End-User Industry

- Aerospace & Defense

- Wind Energy

- Automotive & Transportation

- Construction & Infrastructure

- Marine

- Pipes & Tanks

- Electrical & Electronics

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

The global composite materials market at USD 117 Million in 2023.

The global composite materials market is expected to reach USD 230.01 Million by 2028, growing at a CAGR of 7.8% between 2024 to 2032.

Some of the key factors driving the global composite materials market are due rising demand for carbon fibers among the end-user application, especially in the aerospace & defense applications. In the past few years the automotive segment has become progressively obsessive with consumption of carbon fiber. The rising use of carbon fiber in the automotive sector is due to the factors related to the reduction of carbon footprint, e-mobility and lightweight construction.

North America is expected to grow at a CAGR of over 7% in 2024-2032. The surge is due to the robust growth of electrical and electronics, aerospace and defense and automotive industries. U.S. is the manufacturer of large passenger aircraft, commercial aircraft, defense aircraft and cargo jets which is estimated to fuel the market growth in the estimate period. The aerospace and defense industry is vital to the composite market.

Some of the key players of composite materials market are 3M, Dupont, Dit B.V., Composites Universal Group, Cabot Corporation, Mitsubishi Chemical Corporation, Owens Corning, Teijin Limited, Toray Industries Incorporation and SGL Group among others. Market players are Indulge in various initiatives like research and development, technology innovations, merger & acquisitions and partnerships to manufacture lightweight and cost-effective composite products.

List of Contents

Market InsightsMarket:COVID-19 Impact AnalysisGrowth FactorsFiber Type Segment Analysis Preview End-User Industry Segment Analysis PreviewRegional Analysis Preview Report ScopeKey Market Players Competitive LandscapeThe global composite materials market is segmented as follows:By Fiber TypeBy Resin TypeBy Manufacturing ProcessBy End-User IndustryRelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed