Cold Plate Market Size, Share, Trends, Growth & Forecast 2034

Cold Plate Market By Type (Tube-in-Plate, Deep Drilled, Formed Tube, Pocketed Folded Fin, Machined Channel, Others), By Material (Aluminum, Copper, Stainless Steel, Titanium, Others), By Cooling Medium (Liquid Cooling, Refrigerant Cooling, Others), By Application (Electronics Cooling, Power Electronics, Data Centers, Electric Vehicles, Aerospace and Defense, Medical Equipment, Telecommunications), By End-User (Industrial Manufacturing, Automotive Industry, Information Technology, Healthcare Sector, Defense and Military, Renewable Energy), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

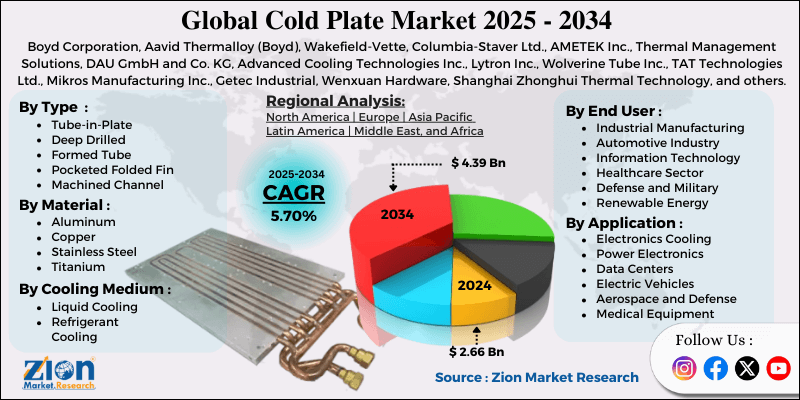

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 2.66 Billion | USD 4.39 Billion | 5.70% | 2024 |

Cold Plate Industry Perspective:

The global cold plate market size was worth approximately USD 2.66 billion in 2024 and is projected to grow to around USD 4.39 billion by 2034, with a compound annual growth rate (CAGR) of roughly 5.70% between 2025 and 2034.

Key Insights:

- As per the analysis shared by our research analyst, the global cold plate market is estimated to grow annually at a CAGR of around 5.70% over the forecast period (2025-2034).

- In terms of revenue, the global cold plate market size was valued at approximately USD 2.66 billion in 2024 and is projected to reach USD 4.39 billion by 2034.

- The cold plate market is projected to grow significantly due to the increasing power density in electronics, rapid electric vehicle adoption, data center expansion, and growing demand for efficient thermal management solutions across multiple industries.

- Based on type, the machined channel segment is expected to lead the cold plate market, while the pocketed folded fin segment is anticipated to experience significant growth.

- Based on material, the aluminum segment is expected to lead the cold plate market, while the copper segment is anticipated to witness notable growth.

- Based on cooling medium, the liquid cooling segment is the dominating segment, while the refrigerant cooling segment is projected to witness sizeable revenue over the forecast period.

- Based on application, the electronics cooling segment is expected to lead the market compared to the electric vehicles segment.

- Based on end user, the automotive industry segment is expected to lead the market, followed by the information technology segment.

- Based on region, North America is projected to dominate the global cold plate market during the estimated period, followed by the Asia Pacific.

Cold Plate Market: Overview

Cold plates are cooling devices designed to remove heat from electronic systems, power equipment, and industrial machines by transferring thermal energy to a liquid coolant that flows through internal channels. These plates are usually made of metal and contain carefully designed pathways that allow coolant to absorb heat from components placed directly on their surface. Modern cold plates are created using techniques such as deep drilling, vacuum brazing, and friction stir welding, which help improve heat transfer while keeping flow resistance low. Engineers choose specific cold plate designs based on required cooling performance, available space, and project budgets. Electronics manufacturers use cold plates to protect processors, graphics units, and memory modules from overheating. Data centers use direct-to-chip cold plate cooling to increase efficiency and reduce energy use. Electric vehicle batteries rely on cold plates to maintain safe, stable temperatures that support performance and long service life. Aerospace, defense, medical equipment, and telecommunications networks also use cold plates for reliable and precise temperature control in demanding environments.

The rising thermal challenges in modern electronics and the push for energy-efficient cooling solutions are expected to drive growth in the cold plate market throughout the forecast period.

Cold Plate Market Dynamics

Growth Drivers

Electric vehicle adoption and battery thermal management

The cold plate market is growing quickly as electric vehicle production increases and companies focus on keeping battery temperatures controlled for safety and performance. Lithium-ion batteries require stable temperatures to deliver high energy density, fast charging, and long service life across a wide range of climates. Battery packs create high heat during fast charging and heavy driving, so cold plates help manage this heat effectively across all cells. Uniform cooling across the full battery pack helps prevent hot spots, slow degradation, and maintain smooth vehicle performance every day. Fast charging stations push high power into batteries, so cooling support protects cells and keeps charging speeds stable across long sessions.

Performance electric vehicles need strong cooling systems for continuous high-power driving without temperature limits, reducing power delivery. Commercial electric trucks and buses use large battery packs, increasing demand for strong and reliable cooling solutions. New battery designs use cold plates as structural parts to reduce weight and support lower manufacturing costs. Regional production of electric vehicles also increases demand for cold plates in growing supply chains.

How are data center expansion and high-performance computing needs driving growth in the cold plate market?

The global cold plate industry is expanding quickly as data centers handle artificial intelligence workloads, cloud services, and growing digital activity needing strong and efficient cooling. Modern processors and graphics units create high heat levels beyond what air cooling can support, encouraging the shift toward liquid cooling systems using cold plates. Large hyperscale data centers use direct-to-chip designs in which cold plates sit directly on processors for better heat removal during continuous operation. Artificial intelligence training requires intense computing power in small spaces, creating heat levels only liquid cooling can manage safely and reliably. Data center energy efficiency improves significantly when liquid cooling replaces heavy air-based systems that use large amounts of electricity. Edge computing sites with limited space depend on cold plates to increase computing density without reducing performance.

Supercomputers and research clusters use cold plates to maintain stable performance during long scientific or engineering workloads. Cryptocurrency mining operations use cold plates to support high hash rates without thermal slowdown. Graphics card makers also use cold plates in liquid-cooled models for gaming and professional use. Growing focus on energy savings and carbon reduction encourages data centers to invest in efficient cold plate cooling solutions.

Restraints

How do complex design and engineering demands restrain the cold plate market?

The cold plate market faces major challenges because designing and building these cooling systems requires detailed engineering and careful planning for many different applications. Each application has unique heat levels, space limits, coolant needs, and environmental conditions, so engineers must create customized solutions for reliable performance. Flow distribution inside cold plates requires advanced analysis to maintain even cooling across the entire surface during continuous operation. Pressure drop calculations must support strong coolant flow while keeping pump power low and system design simple. Material selection involves balancing conductivity, weight, corrosion resistance, cost, and manufacturing limits for each use case.

Mounting surfaces between cold plates and components need precise flatness, proper interface materials, and secure clamping to ensure strong heat transfer. Leak prevention near sensitive electronics requires strong joining methods, careful testing, and proven long-term durability. Thermal cycling can weaken joints or create leaks unless designs manage expansion and contraction safely. Manufacturing tolerances influence cooling capacity and flow behavior, underscoring the need for precise fabrication.

Opportunities

How is the renewable energy sector creating new opportunities for the cold plate market?

The cold plate industry is growing quickly as renewable energy systems expand and create higher heat levels in power electronics and energy storage equipment. Solar inverters convert panel power into grid power and produce heavy heat loads that cold plates remove with steady performance. Wind turbine converters operate in harsh environments, so cold plates provide reliable cooling during temperature changes and continuous vibration. Battery energy storage systems used for grid support need cooling for both electronic controls and storage cells during charging and discharging.

Fast-charging stations for electric vehicles use high-power electronics, creating concentrated heat that requires strong cooling support for safe operation. Hydrogen electrolyzers producing green hydrogen use power electronics and electrochemical stacks requiring precise temperature control during long operating cycles. Fuel cell systems for backup power and transportation also need cooling for stacks and electrical components. Offshore wind farms depend on cold plates for stable cooling in difficult marine environments. As development advances, microgrids require reliable power-conversion cooling, and electric aircraft need lightweight cold plates for motors and batteries.

Challenges

Cost pressures and price sensitivity

The cold plate industry faces several challenges because costs, pricing pressure, and return-on-investment concerns influence how customers choose thermal solutions. Custom engineering for each application limits economies of scale and keeps cold plates more expensive than standardized cooling products in many markets. Material prices for aluminum, copper, and special alloys fluctuate with global commodity trends, creating uncertainty for both manufacturers and buyers. Advanced production methods, including vacuum brazing, friction stir welding, and precision machining, require skilled labor and specialized tools, increasing final costs.

Many cold plate applications involve small production volumes, reducing opportunities for cost reduction through mass manufacturing approaches. Customers often compare cold plate prices with air cooling without considering long-term efficiency savings or performance benefits in demanding environments. Complete liquid-cooling systems also require pumps, reservoirs, heat exchangers, and controls, which add costs beyond the cost of the cold plate alone. Installation work and system integration create additional expenses for users without experience with liquid cooling. Maintenance needs, including coolant replacement, filter changes, and leak checks, add ongoing operational costs.

Cold Plate Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Cold Plate Market |

| Market Size in 2024 | USD 2.66 Billion |

| Market Forecast in 2034 | USD 4.39 Billion |

| Growth Rate | CAGR of 5.70% |

| Number of Pages | 214 |

| Key Companies Covered | Boyd Corporation, Aavid Thermalloy (Boyd), Wakefield-Vette, Columbia-Staver Ltd., AMETEK Inc., Thermal Management Solutions, DAU GmbH and Co. KG, Advanced Cooling Technologies Inc., Lytron Inc., Wolverine Tube Inc., TAT Technologies Ltd., Mikros Manufacturing Inc., Getec Industrial, Wenxuan Hardware, Shanghai Zhonghui Thermal Technology, and others. |

| Segments Covered | By Type, By Material, By Cooling Medium, By Application, By End User, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Cold Plate Market: Segmentation

The global cold plate market is segmented based on type, material, cooling medium, application, end-user, and region.

Based on type, the global cold plate industry is categorized into tube-in-plate, deep drilled, formed tube, pocketed folded fin, machined channel, and others. Machined channel cold plates lead the market due to their design flexibility, excellent thermal performance, and suitability for high-reliability applications in aerospace and medical equipment.

Based on material, the industry is segmented into aluminum, copper, stainless steel, titanium, and others. Aluminum leads the market due to its excellent combination of thermal conductivity and light weight, ease of manufacturing and machining, and cost-effectiveness compared to copper in many applications.

Based on cooling medium, the global cold plate market is divided into liquid cooling, refrigerant cooling, and others. Liquid cooling is expected to lead the market during the forecast period due to its high heat capacity, flexibility in coolant selection for different applications, and proven reliability across diverse operating environments.

Based on application, the global market is classified into electronics cooling, power electronics, data centers, electric vehicles, aerospace and defense, medical equipment, and telecommunications. Electronics cooling holds the largest market share due to the industrial systems, computing equipment, and telecommunications infrastructure, as power densities continue to increase.

Based on end-user, the market is segregated into industrial manufacturing, automotive industry, information technology, healthcare sector, defense and military, and renewable energy. The automotive industry is expected to lead, driven by the rapid adoption of electric vehicles and the increasing electronic content across all vehicle types, which require sophisticated thermal management solutions.

Cold Plate Market: Regional Analysis

North America leads the global market

North America leads the cold plate market due to strong technology activity, advanced manufacturing capabilities, and early adoption of modern thermal management solutions. The United States hosts major data center operations for companies including Amazon, Google, Microsoft, and Facebook, creating continuous demand for efficient cooling systems. Technology hubs such as Silicon Valley push innovation in electronics cooling as companies develop high-performance products needing reliable heat control. Electric vehicle production is growing quickly as Tesla, General Motors, Ford, and new manufacturers expand battery and vehicle facilities across the region. The aerospace and defense sector includes Boeing, Lockheed Martin, and Northrop Grumman, all requiring specialized cold plates for demanding applications. National laboratories and research centers use liquid cooling for supercomputers and scientific computing systems.

The region also supports experienced thermal management manufacturers with strong engineering skills and established production capacity. Intellectual property protection and research investment encourage ongoing innovation in cold plate designs and manufacturing methods. Higher energy costs motivate data centers to adopt efficient cooling, while environmental rules and corporate sustainability goals increase interest in energy-saving technologies. Growth in medical device production and 5G network expansion adds further demand for dependable cooling solutions.

Why is Asia Pacific experiencing significant growth in the cold plate market?

Asia Pacific is experiencing strong growth in the cold plate market as manufacturing expands across the region and local industries advance in electronics and electric vehicle production. China leads global electric vehicle adoption, with companies including BYD, NIO, and XPeng increasing battery production and driving greater demand for thermal management solutions. Electronics manufacturing in China, Taiwan, South Korea, and Southeast Asia creates high demand for cooling in consumer products and industrial systems. Data center construction is rising rapidly across China, India, and Southeast Asia to support the growth of digital services and larger internet user bases. Japan’s precision manufacturing strengths support domestic cold plate production for automotive and electronics applications.

South Korea’s semiconductor industry and global electronics brands encourage the use of advanced cooling systems in high-performance devices. India’s expanding information technology sector and developing electric vehicle industry are creating new opportunities for thermal management. Taiwan’s strong semiconductor and electronics supply chains make it both a major producer of cold plates and a growing user. The region benefits from lower manufacturing costs, strong supply chains, and supportive government policies for electric vehicles and charging networks. Tropical climates increase cooling needs, while rising consumer electronics ownership adds further demand. Manufacturing clusters across Asia also support close cooperation between cold plate suppliers and equipment manufacturers.

Recent Market Developments:

- In September 2025, Boyd Corporation announced it had delivered five million liquid cold plates to hyperscale data centers supporting AI processors and high-density compute racks.

- In November 2025, Eaton Corporation signed a definitive agreement to acquire the thermal business of Boyd Thermal (a subsidiary of Boyd Corporation) for U.S. $9.5 billion, expanding its liquid cooling and cold plate solution offerings for data centers and EV battery systems.

Cold Plate Market: Competitive Analysis

The leading players in the global cold plate market are:

- Boyd Corporation

- Aavid Thermalloy (Boyd)

- Wakefield-Vette

- Columbia-Staver Ltd.

- AMETEK Inc.

- Thermal Management Solutions

- DAU GmbH and Co. KG

- Advanced Cooling Technologies Inc.

- Lytron Inc.

- Wolverine Tube Inc.

- TAT Technologies Ltd.

- Mikros Manufacturing Inc.

- Getec Industrial

- Wenxuan Hardware

- Shanghai Zhonghui Thermal Technology

The global cold plate market is segmented as follows:

By Type

- Tube-in-Plate

- Deep Drilled

- Formed Tube

- Pocketed Folded Fin

- Machined Channel

- Others

By Material

- Aluminum

- Copper

- Stainless Steel

- Titanium

- Others

By Cooling Medium

- Liquid Cooling

- Refrigerant Cooling

- Others

By Application

- Electronics Cooling

- Power Electronics

- Data Centers

- Electric Vehicles

- Aerospace and Defense

- Medical Equipment

- Telecommunications

By End User

- Industrial Manufacturing

- Automotive Industry

- Information Technology

- Healthcare Sector

- Defense and Military

- Renewable Energy

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed