Synthetic Polyisoprene Rubber Market Size, Share, Trends, Growth 2034

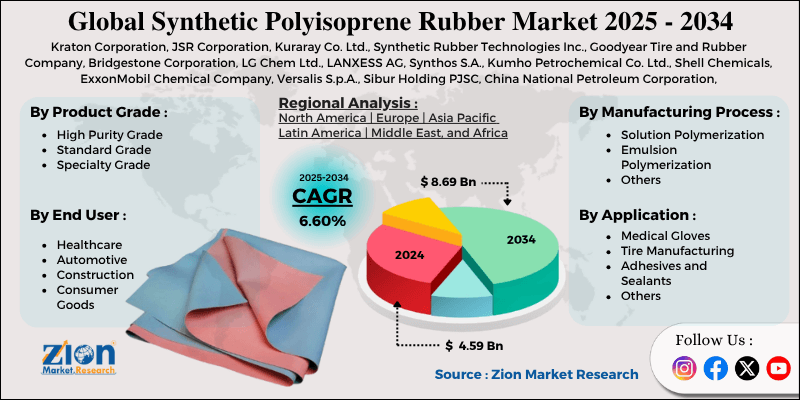

Synthetic Polyisoprene Rubber Market By Product Grade (High Purity Grade, Standard Grade, and Specialty Grade), By Application (Medical Gloves, Tire Manufacturing, Adhesives and Sealants, and Others), By End-User Industry (Healthcare, Automotive, Construction, and Consumer Goods), By Manufacturing Process (Solution Polymerization, Emulsion Polymerization, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

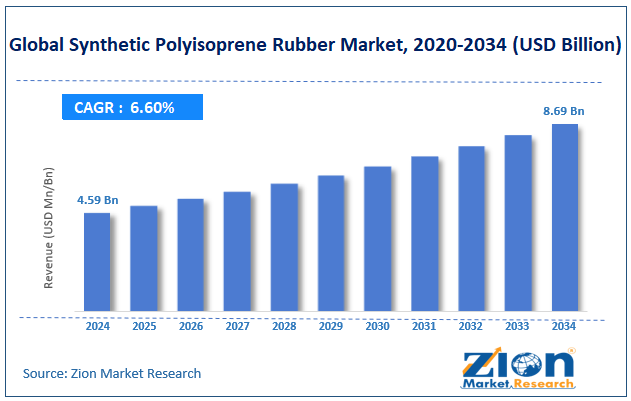

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 4.59 Billion | USD 8.69 Billion | 6.60% | 2024 |

Synthetic Polyisoprene Rubber Industry Perspective:

The global synthetic polyisoprene rubber market was valued at approximately USD 4.59 billion in 2024 and is expected to reach around USD 8.69 billion by 2034, growing at a compound annual growth rate (CAGR) of roughly 6.60% between 2025 and 2034.

Synthetic Polyisoprene Rubber Market: Overview

Synthetic polyisoprene rubber is a high-performance elastomer that mimics the molecular structure and properties of natural rubber, offering improved consistency, purity, and performance. This advanced synthetic material is produced through a controlled polymerization process that creates long-chain molecules with excellent elasticity, tear resistance, and biocompatibility.

The synthetic polyisoprene rubber market serves a diverse range of industries, including healthcare manufacturers, automotive companies, construction companies, and consumer goods manufacturers.

Products are available in multiple molecular weights, viscosity grades, and specialized formulations for specific applications, ranging from medical devices to industrial components. Its latex-free nature makes it ideal for sensitive environments where allergic reactions to natural rubber are a concern.

The growing demand for latex-free medical products and rising construction activities worldwide are expected to drive substantial growth in the global synthetic polyisoprene rubber industry over the forecast period.

Key Insights

- As per the analysis shared by our research analyst, the global synthetic polyisoprene rubber market is estimated to grow annually at a CAGR of around 6.60% over the forecast period (2025-2034)

- In terms of revenue, the global synthetic polyisoprene rubber market size was valued at around USD 4.59 billion in 2024 and is projected to reach USD 8.69 billion by 2034

- The synthetic polyisoprene rubber market is projected to grow significantly due to the increasing demand for high-performance elastomers, rising healthcare applications, and growing automotive production globally.

- Based on product grade, high-purity grade leads the segment and will continue to dominate the global market.

- Based on the application, medical gloves are expected to lead the market.

- Based on the end-user industry, healthcare is anticipated to command the largest market share.

- Based on the manufacturing process, solution polymerization is expected to lead the market during the forecast period.

- Based on region, Asia Pacific is projected to lead the global market during the forecast period.

Synthetic Polyisoprene Rubber Market: Growth Drivers

Increasing demand for latex-free medical products

The global synthetic polyisoprene rubber market is growing as demand for latex-free medical products and devices increases. Natural rubber latex allergies affect millions of healthcare workers and patients worldwide, underscoring a huge need for hypoallergenic alternatives. Synthetic polyisoprene rubber has the same performance as natural rubber, but without the allergenic proteins that cause reactions.

Healthcare facilities are transitioning to latex-free environments to protect both staff and patients, thereby increasing the demand for synthetic polyisoprene rubber. The increasing awareness of latex allergies among healthcare professionals, combined with regulatory requirements for a safer medical environment, has accelerated the shift to synthetic polyisoprene rubber products.

Expanding automotive industry and tire manufacturing

The automotive sector is a key driver of growth for the synthetic polyisoprene rubber industry, particularly in the manufacture of tires and automotive parts. Synthetic polyisoprene rubber has better consistency in quality than natural rubber, which can vary depending on weather and harvesting methods.

Tire manufacturers prefer the predictable performance, tear resistance, and durability that synthetic polyisoprene rubber offers. The material enables the production of high-performance tires with improved fuel efficiency, extended lifespan, and enhanced road grip.

Rising automotive production in emerging markets, increasing vehicle ownership, and growing demand for premium tires are driving massive consumption of synthetic polyisoprene rubber in the auto sector.

Synthetic Polyisoprene Rubber Market: Restraints

High production costs and energy requirements

Despite the growing demand, the synthetic polyisoprene rubber industry faces numerous challenges, including high production costs and energy-intensive processes. The polymerization process requires sophisticated equipment, precise temperature control, and specialized catalysts, resulting in a higher capital investment compared to natural rubber processing.

Energy costs account for a significant portion of the production cost, as the process involves numerous heating and cooling cycles. The raw material cost of monomers and catalysts can be volatile, which affects the profit margin and pricing. All these factors make synthetic polyisoprene rubber expensive than natural rubber; hence, it is limited to price-sensitive applications and markets.

Synthetic Polyisoprene Rubber Market: Opportunities

Development of bio-based synthetic rubber alternatives

The synthetic polyisoprene rubber market presents numerous opportunities, particularly in bio-based production and sustainable manufacturing. Research on bio-based isoprene production using renewable feedstock, such as biomass and agricultural waste, can reduce dependence on petroleum-based raw materials.

Advanced biotechnology, such as genetically modified organisms and fermentation processes, can sustainably produce isoprene monomers. These can address environmental concerns while maintaining the performance of synthetic polyisoprene rubber.

Companies investing in green chemistry and sustainable production can differentiate their products in environmentally conscious markets and potentially reduce long-term costs.

Synthetic Polyisoprene Rubber Market: Challenges

Competition from natural rubber and alternative synthetics

The synthetic polyisoprene rubber market faces intense competition from natural rubber and other synthetic elastomer alternatives. Natural rubber remains cost-competitive in many applications and benefits from established supply chains and processing infrastructure.

Alternative synthetic rubbers, such as styrene-butadiene rubber and polybutadiene rubber, offer lower costs for applications where the unique properties of synthetic polyisoprene rubber are not essential.

Price competition from these alternatives limits market expansion in cost-sensitive segments. Additionally, improvements in natural rubber processing and quality control reduce some of the traditional advantages of synthetic alternatives.

Synthetic Polyisoprene Rubber Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Synthetic Polyisoprene Rubber Market |

| Market Size in 2024 | USD 4.59 Billion |

| Market Forecast in 2034 | USD 8.69 Billion |

| Growth Rate | CAGR of 6.60% |

| Number of Pages | 214 |

| Key Companies Covered | Kraton Corporation, JSR Corporation, Kuraray Co. Ltd., Synthetic Rubber Technologies Inc., Goodyear Tire and Rubber Company, Bridgestone Corporation, LG Chem Ltd., LANXESS AG, Synthos S.A., Kumho Petrochemical Co. Ltd., Shell Chemicals, ExxonMobil Chemical Company, Versalis S.p.A., Sibur Holding PJSC, China National Petroleum Corporation, Reliance Industries Limited, Indian Oil Corporation Limited, Bharat Petroleum Corporation Limited, LyondellBasell Industries Holdings B.V., SABIC, and others. |

| Segments Covered | By Product Grade, By Application, By End User Industry, By Manufacturing Process, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Synthetic Polyisoprene Rubber Market: Segmentation

The global synthetic polyisoprene rubber market is segmented into product grade, application, end-user industry, manufacturing process, and region.

Based on product grade, the market is segregated into high purity grade, standard grade, and specialty grade. High purity grade leads the market due to its superior performance characteristics, consistent quality, and suitability for demanding applications in healthcare and high-performance industrial uses.

Based on application, the synthetic polyisoprene rubber industry is classified into medical gloves, tire manufacturing, adhesives and sealants, and others. Medical gloves hold the largest market share due to the growing demand for latex-free medical products, increasing healthcare awareness, and regulatory requirements for safer medical environments.

Based on the end-user industry, the synthetic polyisoprene rubber market is divided into healthcare, automotive, construction, and consumer goods. Healthcare is expected to lead the market during the forecast period, driven by increasing medical device production, growing awareness of latex allergies, and the expansion of global healthcare infrastructure.

Based on the manufacturing process, the market is segmented into solution polymerization, emulsion polymerization, and others. Solution polymerization leads the market share due to its ability to produce higher molecular weight polymers, better control over polymer structure, and superior product consistency.

Synthetic Polyisoprene Rubber Market: Regional Analysis

Asia Pacific to lead the market

Asia Pacific leads the synthetic polyisoprene rubber market due to rapid industrialization, growing healthcare infrastructure, and huge automotive production capacity. The region accounts for around 40% of the global market share. China, Japan, and South Korea are the largest consumers of synthetic polyisoprene rubber products.

The large population and growing middle class are driving demand for healthcare products and automotive vehicles, which in turn support market growth. Investments in healthcare infrastructure and medical device manufacturing are creating a huge demand for latex-free medical products. The development of the automotive industry in countries such as India, Thailand, and Vietnam is driving demand for tire manufacturing.

Lower production costs and government support for industrial development are further adding to the region’s market. Increasing export activity of rubber-based goods from the area is boosting synthetic polyisoprene consumption. Rising investments from global manufacturers setting up production facilities in Southeast Asia further support long-term growth.

North America is expected to grow steadily.

North America is a steadily growing synthetic polyisoprene rubber industry, driven by advanced healthcare systems, stringent safety regulations, and high-performance automotive applications. Medical device innovation and the adoption of latex-free healthcare environments support steady demand growth.

A strong automotive industry presence and demand for premium tire products create steady consumption patterns. The region prioritizes product quality and performance over cost, and synthetic polyisoprene rubber is the preferred choice. Biocompatible materials requirements in medical applications and automotive safety standards ensure market stability and growth.

Expansion in domestic manufacturing capabilities and research into high-performance elastomers are further strengthening the market. Increased focus on sustainable and recyclable rubber alternatives is also influencing product innovation and demand.

Recent Market Developments

- In April 2025, Synthetic Rubber Technologies announced the expansion of its high-purity synthetic polyisoprene rubber production facility in Texas, increasing capacity by 30% to meet growing demand in the healthcare sector.

Synthetic Polyisoprene Rubber Market: Competitive Analysis

The global synthetic polyisoprene rubber market is led by players like:

- Kraton Corporation

- JSR Corporation

- Kuraray Co. Ltd.

- Synthetic Rubber Technologies Inc.

- Goodyear Tire and Rubber Company

- Bridgestone Corporation

- LG Chem Ltd.

- LANXESS AG

- Synthos S.A.

- Kumho Petrochemical Co. Ltd.

- Shell Chemicals

- ExxonMobil Chemical Company

- Versalis S.p.A.

- Sibur Holding PJSC

- China National Petroleum Corporation

- Reliance Industries Limited

- Indian Oil Corporation Limited

- Bharat Petroleum Corporation Limited

- LyondellBasell Industries Holdings B.V.

- SABIC

The global synthetic polyisoprene rubber market is segmented as follows:

By Product Grade

- High Purity Grade

- Standard Grade

- Specialty Grade

By Application

- Medical Gloves

- Tire Manufacturing

- Adhesives and Sealants

- Others

By End User Industry

- Healthcare

- Automotive

- Construction

- Consumer Goods

By Manufacturing Process

- Solution Polymerization

- Emulsion Polymerization

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Synthetic polyisoprene rubber is a high-performance elastomer that closely mimics the molecular structure and properties of natural rubber while offering superior consistency, purity, and performance characteristics through controlled polymerization processes.

The synthetic polyisoprene rubber market is expected to be driven by increasing demand for latex-free medical products, expanding automotive production, growing healthcare infrastructure, rising awareness of latex allergies, technological advancements in polymer science, and the growing adoption of polyisoprene in high-performance applications.

According to our study, the global synthetic polyisoprene rubber market was worth around USD 4.59 billion in 2024 and is predicted to grow to around USD 8.69 billion by 2034.

The CAGR value of the synthetic polyisoprene rubber market is expected to be around 6.60% during 2025-2034.

The global synthetic polyisoprene rubber market is expected to register the highest revenue contribution from the Asia Pacific during the forecast period.

Key players in the synthetic polyisoprene rubber market include Kraton Corporation, JSR Corporation, Kuraray Co. Ltd., Synthetic Rubber Technologies Inc., Goodyear Tire and Rubber Company, Bridgestone Corporation, LG Chem Ltd., LANXESS AG, Synthos S.A., Kumho Petrochemical Co. Ltd., Shell Chemicals, ExxonMobil Chemical Company, Versalis S.p.A., Sibur Holding PJSC, China National Petroleum Corporation, Reliance Industries Limited, Indian Oil Corporation Limited, Bharat Petroleum Corporation Limited, LyondellBasell Industries Holdings B.V., and SABIC.

The report provides a comprehensive analysis of the synthetic polyisoprene rubber market, including an in-depth examination of market drivers, restraints, emerging trends, regional dynamics, and future growth prospects. It also examines competitive dynamics, production technologies, application innovations, and the evolving industrial requirements shaping the advanced materials industry ecosystem.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed