Synthetic Resins Market Size, Share, Trends, Growth and Forecast 2032

Synthetic Resins Market, by Product Type (Thermoplastic Resins and Thermosetting Resin); for Application (Packaging, Building Supplies, Automotive, Electronics, and Others) - Japan and South Korea Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2024 - 2032

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 442.31 Billion | USD 680.32 Billion | 4.90% | 2023 |

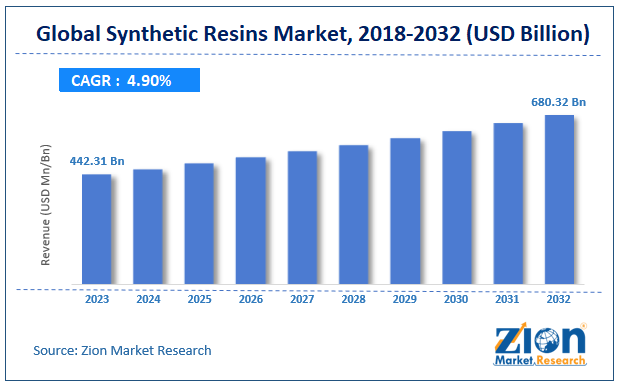

The global Synthetic Resins Market size was worth around USD 442.31 Billion in 2023 and is predicted to grow to around USD 680.32 Billion by 2032 with a compound annual growth rate (CAGR) of roughly 4.90% between 2024 and 2032.

Synthetic Resins Market: Industry Perspective

The growth of the market can be attributed to the increasing demand for Synthetic Resin owning to the Packaging, Building Material, Automotive, Electronics, Othes Applications across the global level. The report provides insights regarding the lucrative opportunities in the Synthetic Resin Market at the country level. The report also includes a precise cost, segments, trends, region, and commercial development of the major key players globally for the projected period.

Request Free Sample

Request Free Sample

The Synthetic Resin Market report represents gathered information about a market within an industry or various industries. The Synthetic Resin Market report includes analysis in terms of both quantitative and qualitative data with a forecast period of the report extending from 2023 to 2032. The report is prepared to take into consideration various factors such as Product pricing, Product or services penetration at both country and regional levels, Country GDP, market dynamics of parent market & child markets, End application industries, major players, consumer buying behavior, economic, political, social scenarios of countries, many others. The report is divided into various segments to offer a detailed analysis of the market from every possible aspect of the market.

The overall report focuses on primary sections such as – market segments, market outlook, competitive landscape, and company profiles. The segments provide details in terms of various perspectives such as end-use industry, product or service type, and any other relevant segmentation as per the market’s current scenario which includes various aspects to perform further marketing activity. The market outlook section gives a detailed analysis of market evolution, growth drivers, restraints, opportunities, and challenges, Porter’s 5 Force’s Framework, macroeconomic analysis, value chain analysis and pricing analysis that directly shape the market at present and over the forecasted period. The drivers and restraints cover the internal factors of the market whereas opportunities and challenges are the external factors that are affecting the market. The market outlook section also gives an indication of the trends influencing new business development and investment opportunities.

Synthetic Resins Market Report Brief

- The report covers forecast and analyses for the synthetic resins market on both country levels.

- The report also provides historical data on the market for a better understanding of the dynamics and trends prevalent in the market.

- The report includes the positive and the negative factors that are influencing the growth of the market.

- Detailed information about the market opportunities and challenges is discussed.

- The key target audience for the market has been determined in the report.

- The volume of the synthetic resin sales has been determined in kilotons.

- The revenue generated by the prominent industry players has been analyzed in the report.

- The market numbers have been calculated using top-down and bottom-up approaches along with data triangulation.

- The synthetic resins market has been analyzed using Porter’s Five Forces Analysis.

- The market is segmented on the basis of product type and application which in turn are bifurcated on a country level.

- All the segments have been evaluated based on the present and future key industry trends.

- The report deals with in-depth quantitative and qualitative analyses of the synthetic resin market.

- The report includes detailed company profiles of the prominent market players.

- The report comprises a detailed list of suppliers of synthetic resins and buyers (end-users).

- The report provides key trends and key takeaways observed in the market.

Synthetic resins are non-crystalline or viscous liquid substances. They consist of numerous synthetic materials which have similar properties to natural resins. However, the chemical composition of synthetic resins is different from natural resins. Synthetic resins are broadly differentiated into thermoplastic and thermosetting synthetic resins based on the procedure of their formation processes (esterification and/or soaping of organic compounds). Some of the common thermoplastic synthetic resins include polyethylene, polypropylene, ABS, PET, PVC, polycarbonate, polyurethane, and nylon, among others. Some of the common thermosetting synthetic resins include phenolics, polyurethanes, and epoxy resins, among others.

Synthetic Resins Market: Drivers and Restraints

The major factor driving the growth of the synthetic resin market is the increased use of lightweight components to address stringent regulations. Lightweight components have a huge demand in various end-user industries since regulatory taxes and duties could be prevented if the weight of finished products is kept under specified limits. Since most of these lightweight components are manufactured with synthetic resins as raw materials, the demand for synthetic resins is expected to grow during the forecast period.

Metals are increasingly getting replaced with plastics and composite materials to save cost and reduce weight. Thus, increasing penetration of composite materials for replacing metals is also expected to boost the demand for synthetic resins in Japan and South Korea.

Environmental concerns regarding the inability for natural decomposition of some of these synthetic resin materials are expected to limit the growth of synthetic resins during the forecast period in these countries.

Synthetic Resins Market: Segmentation

Thermoplastic resins offer numerous advantages such as high recyclability, high-impact resistance, reshaping capabilities, chemical resistance, aesthetically superior finishes, hard crystalline or rubbery surface options, and an eco-friendly manufacturing process over thermoset resins. In the product type segment, thermoplastic resins held a leading share of more than 80%, in 2016. Thermoplastics are processed using various methods such as injection molding, extrusion, and thermoforming, among others.

Packaging products are mostly made from thermosetting resins such as phenolic & epoxy resins as well as from thermoplastics such as polypropylene among others. Increasing packaging requirements for consumer goods, electronics, and durables among various other goods and products have boosted the demand for synthetic resins in a packaging applications. Additionally, the automotive and electronics applications are expected to grow at leading rates of more than 3%.

Japan dominated the Japan and South Korea synthetic resins market with around 60% share, in 2016. The dynamic presence and increasing number of manufacturing industries such as automotive and electronics among others are expected to drive the synthetic resins market in Japan during the forecast period. Thermoplastic resins dominate the Japanese synthetic resins market.

Synthetic Resins Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Synthetic Resins Market Size Report |

| Market Size in 2023 | USD 442.31 Billion |

| Market Forecast in 2032 | USD 680.32 Billion |

| Growth Rate | CAGR of 4.90% |

| Number of Pages | 188 |

| Forecast Units | Value (USD Billion), and Volume (Units) |

| Key Companies Covered | BASF, Du Pont, Dow, Nanya, Momentive, Kukdo, Gellner Industrial, LLC, Synresins Ltd, CCP, Huntsman, MCC, UPC, Bayer, DSM, Akolite, Sinopec, Formosa Plastic Group, Synresins, HUNTSMAN, Purolite, DIC, BLUESTAR, San Mu. |

| Segments Covered | By Type - Thermoplastic Resin, Thermosetting Resin By Application - Packaging, Building Material, Automotive, Electronics, Othes By Geography - North America, Europe, APAC, Middle East Asia & Rest Of World. |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Synthetic Resins Market: Industry Players

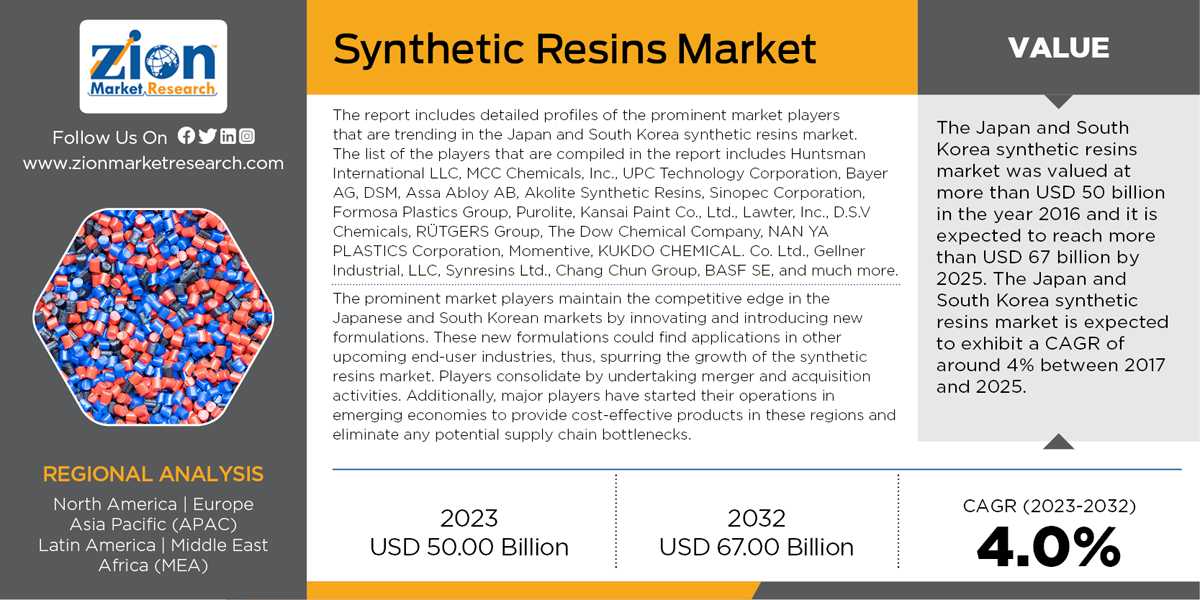

The report includes detailed profiles of the prominent market players that are trending in the Japan and South Korea synthetic resins market. The list of the players that are compiled in the report includes -

- BASF

- Du Pont

- Dow

- Nanya

- Momentive

- Kukdo

- Gellner Industrial

- LLC

- Synresins Ltd

- CCP

- Huntsman

- MCC

- UPC

- Bayer

- DSM

- Akolite

- Sinopec

- Formosa Plastic Group

- Synresins

- HUNTSMAN

- Purolite

- DIC

- BLUESTAR

- San Mu.

The prominent market players maintain the competitive edge in the Japanese and South Korean markets by innovating and introducing new formulations. These new formulations could find applications in other upcoming end-user industries, thus, spurring the growth of the synthetic resins market. Players consolidate by undertaking merger and acquisition activities. Additionally, major players have started their operations in emerging economies to provide cost-effective products in these regions and eliminate any potential supply chain bottlenecks.

Synthetic Resin Market Segmentation

By Type

- Thermoplastic Resin

- Thermosetting Resin

By Application

- Packaging

- Building Material

- Automotive

- Electronics

- Othes

By Geography

- North America

- Europe

- Asia Pacific

- Middle East & Africa

- Latin America

Table Of Content

Methodology

FrequentlyAsked Questions

The global Synthetic Resins Market size was worth around USD 442.31 Billion in 2023 and is predicted to grow to around USD 680.32 Billion by 2032

compound annual growth rate (CAGR) of roughly 4.90% between 2024 and 2032.

The largest share of the Synthetic Resins Market is held by Asia Pacific. Developing countries of Asia Pacific such as China, Japan, and India will be dominating the market scenario mainly due to the rising constructional activities. The growth of Asia-Pacific region is expected to be followed by the Middle East and North America. Also, significant growth is expected from Western Europe owing to the developments taking place in this region especially in countries such as Italy, Germany, the U.K, France, and Spain. However, growth in Africa, Latin America, and Eastern Europe is anticipated to be moderate over the forecast period.

BASF, Du Pont, Dow, Nanya, Momentive, Kukdo, Gellner Industrial, LLC, Synresins Ltd, CCP, Huntsman, MCC, UPC, Bayer, DSM, Akolite, Sinopec, Formosa Plastic Group, Synresins, HUNTSMAN, Purolite, DIC, BLUESTAR, San Mu

RelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed