Global Sintered Brake Pads Market Size, Share, Growth Analysis Report - Forecast 2034

Sintered Brake Pads Market By Type (Road Sintered Brake Pads, Rail Sintered Brake Pads, Wind Turbine Sintered Brake Pads), By Application (OEM, Aftermarket), and By Region: Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

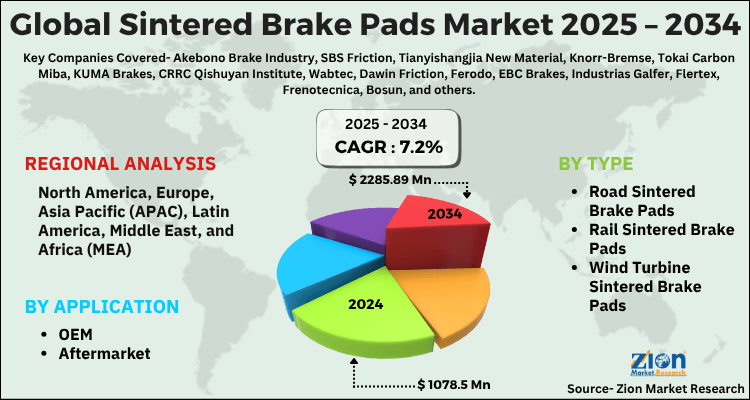

| USD 1078.5 Million | USD 2285.89 Million | 7.2% | 2024 |

Sintered Brake Pads Market: Industry Perspective

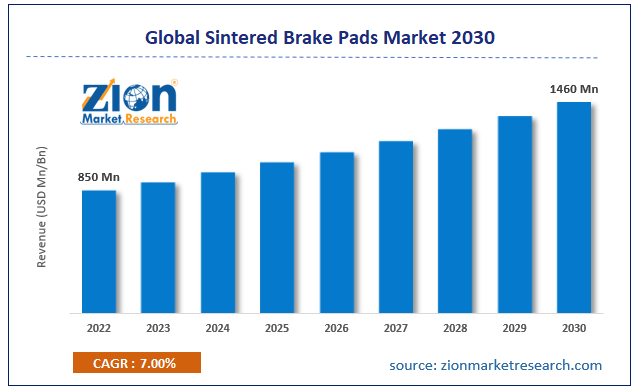

The global sintered brake pads market size was worth around USD 1078.5 Million in 2024 and is predicted to grow to around USD 2285.89 Million by 2034 with a compound annual growth rate (CAGR) of roughly 7.2% between 2025 and 2034. The report analyzes the global sintered brake pads market's drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the sintered brake pads industry.

Sintered Brake Pads Market: Overview

Metal particles are fused at a high temperature and pressure to create sintered brake pads, also known as metal sintered or metallic brake pads. Sintered brake pads are employed in the majority of OEM applications, not just on mountain bikes but also on motorcycles and vehicles due to their versatility. In muddy and rainy trail conditions, sintered brake pads will maintain their previous level of traction. Because sintered brake pads might be less influenced by heat buildup, they may perform better for riders that race. Heat production increases as brake pressure increases. On those lengthy, steep descents, sintered brake pads won't fade as much as organic brake pads. The sintered brake pads market is being driven by several factors such as the growing automotive industry, increasing safety regulations & standards, rising demand for high-performance vehicles, and expansion of off-road & recreational vehicles.

Key Insights

- As per the analysis shared by our research analyst, the global sintered brake pads market is estimated to grow annually at a CAGR of around 7.2% over the forecast period (2025-2034).

- Regarding revenue, the global sintered brake pads market size was valued at around USD 1078.5 Million in 2024 and is projected to reach USD 2285.89 Million by 2034.

- The sintered brake pads market is projected to grow at a significant rate due to rising demand for high-performance braking systems in automotive, aerospace, and industrial applications, advancements in manufacturing technologies enhancing product durability and heat resistance, and the growing adoption of electric vehicles requiring specialized braking solutions.

- Based on Type, the Road Sintered Brake Pads segment is expected to lead the global market.

- On the basis of Application, the OEM segment is growing at a high rate and will continue to dominate the global market.

- Based on region, Asia-Pacific is predicted to dominate the global market during the forecast period.

Sintered Brake Pads Market: Dynamics

Key Growth Drivers:

Rising global vehicle production (especially two-wheelers and commercial fleets), expanding aftermarket demand, and the push for higher-performance and longer-lasting braking systems are primary drivers for the sintered brake pads market. Sintered formulations offer superior friction stability, high-temperature performance and wear resistance—attributes favored in heavy-duty, off-road, motorcycle and motorsport applications—driving OEM and retrofit adoption. Additionally, improving road infrastructure in emerging markets and stricter safety standards encourage fleet upgrades and replacement cycles, supporting steady demand.

Restraints:

Higher manufacturing costs and price sensitivity—particularly versus organic/ceramic alternatives—limit widespread replacement of conventional pads. Regulatory pressure and environmental concerns over metal particulates (notably copper and certain abrasives) create compliance burdens and potential reformulation costs. Supply-chain volatility for metallic powders and bonding agents, plus noise/vibration (NVH) issues in some sintered compounds, can further slow adoption in cost- and comfort-sensitive passenger-vehicle segments.

Opportunities:

Development of eco-friendly, low-copper or copper-free sintered blends and advanced composite formulations opens new markets where regulation is tightening. Growth in commercial vehicle fleets, two-wheeler usage in APAC/Latin America, and specialty sectors (motorsport, mining, military) present premium OEM and aftermarket opportunities. Partnerships with vehicle manufacturers for custom formulations, value-added services (conditioning/coatings), and aftermarket digital channels for fitment and distribution can expand reach. Technological advances in powder metallurgy and additive manufacturing can also reduce cost and improve performance.

Challenges:

The market faces competition from alternative braking materials (ceramic, organic, and semi-metallic pads) that may better meet NVH or emissions targets for some segments. The rise of electric vehicles—with regenerative braking that reduces friction-pad usage—could depress replacement demand in passenger EV fleets over time. Manufacturers must navigate tightening environmental regulations, rising raw-material price volatility, and the high cost and long timelines for testing and regulatory certification across jurisdictions. Balancing performance, cost, and environmental compliance while scaling production remains the sector’s core operational challenge.

Sintered Brake Pads Market: Segmentation

The global Sintered Brake Pads industry is segmented based on type, sales channel, and region. All the segments have been analyzed based on present and future trends and the market is estimated from 2025 to 2034.

Based on the type, the global market is bifurcated into road sintered brake pads, rail sintered brake pads, and wind turbine sintered brake pads. The road sintered brake pads are expected to dominate the market during the forecast period. The segment growth is attributed to the growing automotive industry. Sintered brake pads are widely used in passenger cars, SUVs, and trucks. They provide excellent stopping power, heat resistance, and durability, making them suitable for everyday driving and performance-oriented applications. For instance, according to Invest India, between April 2021 and March 2022, the automobile industry manufactured a total of 22.93 million vehicles, including passenger cars, commercial trucks, three-wheelers, two-wheelers, and quadricycles. India is the largest tractor, second-largest bus, and third-largest heavy truck producer in the world, giving it a significant position in the global heavy vehicle market. As of November 2022, passenger car sales had reached a record-high 25,04,084 units for the fiscal year 2022–23. In FY23, the industry is predicted to rise by 16%. Thus, this is expected to drive the segment growth over the forecast period.

Based on the application, the global Sintered Brake Pads industry is bifurcated into OEM and Aftermarket. The OEM segment is expected to dominate the market over the forecast period. OEMs provide sintered brake pads that are made particularly for certain car models. During the production process, these brake pads are included as original equipment in the automobiles. OEM brake pads are designed to work exactly as intended by the carmaker, according to all of their criteria and specifications. Moreover, OEM sintered brake pads are renowned for their excellent quality, dependability, and consistency. To make sure that the brake pads fulfill safety and performance criteria, automakers have rigid standards and quality control procedures in place. Thereby, driving the segment growth.

The Regional, this segment includes the current and forecast demand for North America, Europe, Asia Pacific, Latin America,and the Middle East and Africa.

Sintered Brake Pads Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Sintered Brake Pads Market |

| Market Size in 2024 | USD 1078.5 Million |

| Market Forecast in 2034 | USD 2285.89 Million |

| Growth Rate | CAGR of 7.2% |

| Number of Pages | 212 |

| Key Companies Covered | Akebono Brake Industry, SBS Friction, Tianyishangjia New Material, Knorr-Bremse, Tokai Carbon Miba, KUMA Brakes, CRRC Qishuyan Institute, Wabtec, Dawin Friction, Ferodo, EBC Brakes, Industrias Galfer, Flertex, Frenotecnica, Bosun, and others. |

| Segments Covered | By Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2020 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Sintered Brake Pads Market: Regional Analysis

From 2025 to 2034, the regional landscape for the sintered brake pads market will be led by Asia-Pacific, where strong demand from China, India and Southeast Asia—driven by expanding two-wheeler fleets, rising commercial vehicle production, rail infrastructure investment and cost-sensitive local manufacturing—will deliver the highest growth and market share; North America will show steady growth supported by commercial transport, logistics fleet expansion, aftermarket replacements and technology adoption in heavy vehicles; Europe will grow moderately as stringent safety and emissions regulations, investments in high-speed and freight rail upgrades, and demand for durable, high-performance materials push adoption in both OEM and aftermarket channels; Latin America will register gradual gains tied to infrastructure projects and modernization of public transport and freight networks, while the Middle East & Africa will see selective growth in oil & gas, border security and railway projects that require robust sintered solutions; overall, regional differences will be shaped by vehicle mix (two-wheelers vs. commercial vs. rail), infrastructure spending, local manufacturing capacity, and regulatory drivers that favor sintered pads for high-load, high-temperature and heavy-duty applications.

Sintered Brake Pads Market: Competitive Analysis

The global Sintered Brake Pads market is dominated by players like:

- Akebono Brake Industry

- SBS Friction

- Tianyishangjia New Material

- Knorr-Bremse

- Tokai Carbon Miba

- KUMA Brakes

- CRRC Qishuyan Institute

- Wabtec

- Dawin Friction

- Ferodo

- EBC Brakes

- Industrias Galfer

- Flertex

- Frenotecnica

- Bosun

The global Sintered Brake Pads market is segmented as follows:

By Type

- Road Sintered Brake Pads

- Rail Sintered Brake Pads

- Wind Turbine Sintered Brake Pads

By Application

- OEM

- Aftermarket

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Metal particles are fused at a high temperature and pressure to create sintered brake pads, also known as metal sintered or metallic brake pads. Sintered brake pads are employed in the majority of OEM applications, not just on mountain bikes but also on motorcycles and vehicles due to their versatility. In muddy and rainy trail conditions, sintered brake pads will maintain their previous level of traction.

The global sintered brake pads market is expected to grow due to increasing demand for high-performance braking systems in the automotive and motorcycle industries, growing production of vehicles (including EVs), rising consumer awareness and stringent regulations regarding vehicle safety.

According to a study, the global sintered brake pads market size was worth around USD 1078.5 Million in 2024 and is expected to reach USD 2285.89 Million by 2034.

The global sintered brake pads market is expected to grow at a CAGR of 7.2% during the forecast period.

Asia-Pacific is expected to dominate the sintered brake pads market over the forecast period.

Leading players in the global sintered brake pads market include Akebono Brake Industry, SBS Friction, Tianyishangjia New Material, Knorr-Bremse, Tokai Carbon Miba, KUMA Brakes, CRRC Qishuyan Institute, Wabtec, Dawin Friction, Ferodo, EBC Brakes, Industrias Galfer, Flertex, Frenotecnica, Bosun, among others.

The report explores crucial aspects of the sintered brake pads market, including a detailed discussion of existing growth factors and restraints, while also examining future growth opportunities and challenges that impact the market.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed