Electric Vehicle Insulation Market Size, Share, Growth & Trends by 2034

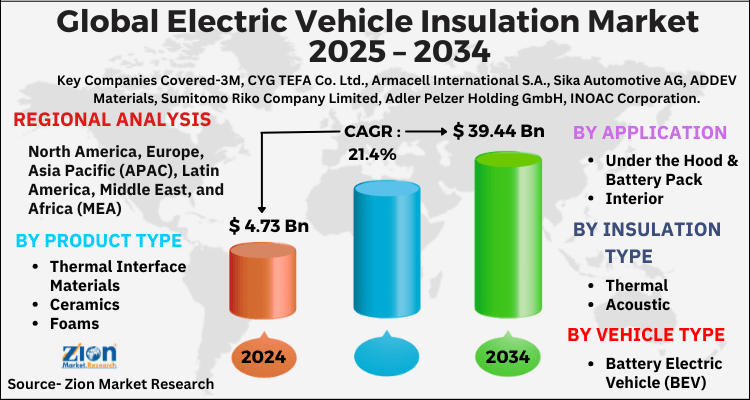

Electric Vehicle Insulation Market By Product Type (Thermal Interface Materials, Ceramics, Foamed Plastics, Fiberglass, and Others), By Application (Under the Hood & Battery Pack, Interior, and Others), By Insulation Type (Thermal, Acoustic, and Electric), By Vehicle Type (Battery Electric Vehicle (BEV), Plug-in Hybrid Electric Vehicle (PHEV), and Hybrid Electric Vehicle (HEV)), and By Region: Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 4.73 Billion | USD 39.44 Billion | 21.4% | 2024 |

Electric Vehicle Insulation Market: Industry Perspective

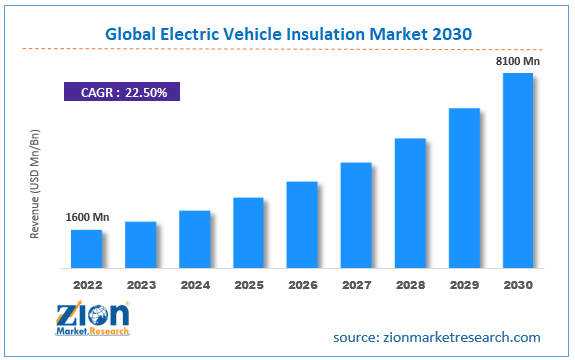

The global electric vehicle insulation market size was worth around USD 4.73 billion in 2024 and is predicted to grow to around USD 39.44 billion by 2034 with a compound annual growth rate (CAGR) of roughly 21.4% between 2025 and 2034. The report analyzes the global electric vehicle insulation market's drivers, restraints/challenges, and the effect they have on the demand during the projection period. In addition, the report explores emerging opportunities in the electric vehicle insulation industry.

Electric Vehicle Insulation Market: Overview

Insulation is used in electric vehicles to reduce the impact of heat, sound, and vibration on the vehicle and the occupants. The performance of the vehicle is impacted by overheating, which also causes motor fluid to evaporate. The vehicle's chassis and hefty gears are also harmed by the shaking. Vehicle insulation prevents these damages from spreading, therefore extending the lifespan and performance of the vehicle and lowering maintenance costs. With these advantages, further electric car adoption is therefore anticipated to enhance product demand.

Key Insights

- As per the analysis shared by our research analyst, the global electric vehicle insulation market is estimated to grow annually at a CAGR of around 21.4% over the forecast period (2025-2034).

- Regarding revenue, the global electric vehicle insulation market size was valued at around USD 4.73 billion in 2024 and is projected to reach USD 39.44 billion by 2034.

- The electric vehicle insulation market is projected to grow at a significant rate due to Growing EV production and the need for thermal, acoustic, and electrical insulation, driving demand. Emphasis on vehicle safety and battery efficiency supports market growth.

- Based on Product Type, the Foamed Plastics segment is expected to lead the global market.

- On the basis of Application, the Under the Hood & Battery Pack segment is growing at a high rate and will continue to dominate the global market.

- Based on the Insulation Type, the Thermal segment is projected to swipe the largest market share.

- By Vehicle Type, the Hybrid Electric Vehicle (HEV) segment is expected to dominate the global market.

- Based on region, Asia-Pacific is predicted to dominate the global market during the forecast period.

Electric Vehicle Insulation Market: Growth Drivers

Increasing pollution drives the market growth over the projection period

As worries about pollution and climate change have grown, people have started to rely more on renewable resources and less on fossil fuels. Apart from that, governments in several nations are implementing stricter pollution standards. For instance, India's 2020 emission standards are more stringent, costing more and producing less pollution than diesel and gasoline engines. As a result, the use of electric vehicles (EVs) has increased. Even with upgraded and costly engines, EVs produce no greenhouse emissions or air pollution in comparison to a petrol or diesel automobile. The decrease in noise pollution is another benefit of EVs. As a result, the global market for electric vehicle insulators is anticipated to develop as pollution levels rise due to an increase in the sales of electric vehicles.

Electric Vehicle Insulation Market: Restraints

Supply chain issues hamper the market growth

The electric vehicle insulation market is dependent on particular materials that can only be obtained from a small geographic area or are subject to market changes. Manufacturers may find it difficult to acquire a reliable and affordable supply if there are any disruptions in the availability of these raw materials. These disruptions might result in supply shortages and increased prices. Additionally, electric vehicle manufacturers may have trouble obtaining enough insulation materials if a key supplier experiences operational or logistical issues and is unable to meet demand. This could cause production delays and possible delays in delivering vehicles to customers, which would ultimately restrain the market's revenue growth.

Electric Vehicle Insulation Market: Opportunities

Technological innovations offer a lucrative opportunity for market expansion

The electric vehicle insulation industry is seeing revenue growth as a result of several technical advancements made by leading firms in terms of product manufacture and development by adding more new features as requested by consumers. For instance, in June 2022, SABIC launched NORYL NHP8000VT3 resin, a state-of-the-art material intended for use in the insulating layer for electric vehicle (EV) battery modules. Through the use of patented technologies, this high-performance polyphenylene ether (PPO)-based resin meets the UL94 V0 standard at just 0.25 mm with non-brominated, non-chlorinated flame retardance, and achieves the highest level of comparative tracking index performance (CTI PLC0). With the help of this remarkable material, EV battery technology has advanced significantly, enhancing occupant safety, lowering weight, and increasing efficiency, eventually extending the range of electric vehicles.

Electric Vehicle Insulation Market: Challenges

Cost efficiency poses a significant challenge to the industry's growth

While electric cars are becoming more popular, they frequently have a greater initial cost than regular internal combustion engine (ICE) automobiles. To make EVs more competitive in the market, insulation materials must balance performance and cost-effectiveness. Manufacturers have a tremendous challenge in lowering the cost of sophisticated insulating materials.

Electric Vehicle Insulation Market: Segmentation Analysis

The global electric vehicle insulation market is segmented based on product type, application, insulation type, vehicle type, and region.

Based on Product Type, the global electric vehicle insulation market is divided into thermal interface materials, ceramics, foamed plastics, fiberglass, and others. The foamed plastics are expected to dominate the market over the projection period. Excellent thermal insulation characteristics, lightweight nature, greater shock absorption properties, and cost-effectiveness are important drivers driving revenue growth in this market. Foamed plastics have poor thermal conductivity, allowing them to efficiently trap and impede heat transmission.

This function guarantees that the battery maintains the proper temperature, preventing overheating and potential injury. Furthermore, because of their high strength-to-weight ratio, foamed plastics are an excellent choice for insulation since they protect without adding unnecessary weight to the vehicle. This weight reduction improves energy efficiency and overall vehicle performance. Because electric car batteries are sensitive to collisions and vibrations, foamed plastic insulators provide a cushioning effect that protects the battery from mechanical strains and potential damage when driving and in the case of an accident. Thereby, driving the segment growth over the forecast period.

On the basis of Application, the global electric vehicle insulation market is bifurcated into under-the-hood & battery pack, interior, and others.

By Insulation Type, the global electric vehicle insulation market is split into thermal, acoustic, and electric. The thermal insulation segment is expected to hold a significant market share over the forecast period because the management of battery packs is seeing an increase in demand for thermal insulation materials. Additionally, using the product to keep the vehicle's interior temperature constant is helping the market expand. Increased battery capacities that are appropriate for long-distance cars have been developed as a result of advancements in battery technology. However, these more modern battery types tend to produce greater heat, which might harm the battery's performance and shorten a vehicle's range. Thus, the use of superior thermal insulation is given the highest priority by EV producers.

In terms of Vehicle Type, the global electric vehicle insulation market is categorized into battery electric vehicle (BEV), plug-in hybrid electric vehicle (PHEV), and hybrid electric vehicle (HEV). The Hybrid Electric Vehicle (HEV) segment is expected to lead the market during the forecast period. The automotive industry is expanding as a result of rising consumer demand for fuel-efficient, environmentally friendly vehicles. Additionally, it is anticipated that during the projection period, regulatory support for the use of hybrid vehicles would increase. A conventional internal combustion engine (ICE) and an electric motor are used to power HEVs. Instead of being plugged in to charge the battery, a hybrid car charges through regenerative braking. These cars exhibit better fuel efficiency than conventional ICE vehicles as a consequence.

Electric Vehicle Insulation Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Electric Vehicle Insulation Market |

| Market Size in 2024 | USD 4.73 Billion |

| Market Forecast in 2034 | USD 39.44 Billion |

| Growth Rate | CAGR of 21.4% |

| Number of Pages | 204 |

| Key Companies Covered | 3M, CYG TEFA Co. Ltd., Armacell International S.A., Sika Automotive AG, ADDEV Materials, Sumitomo Riko Company Limited, Adler Pelzer Holding GmbH, INOAC Corporation, Morgan Advanced Materials plc, Pritex Limited, Autoneum, Tecman Speciality Materials Ltd, Toyota Boshoku Corporation, Zotefoams plc, Unifrax, and others. |

| Segments Covered | By Product Type, By Application, By Insulation Type, By Vehicle Type, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2020 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Electric Vehicle Insulation Market: Regional Analysis

Asia Pacific is expected to hold the largest market share over the forecast period

The Asia Pacific is expected to hold the largest electric vehicle insulation market share over the forecast period. Major factors driving the market's revenue growth in this region include factors like rising initiatives to promote the use of renewable energy, rising adoption of electric vehicles (EVs), and a growing need to increase overall vehicle safety by reducing the risk of electrical failure & fire. To combat the possibility of thermal runaway brought on by battery faults, manufacturers add advanced cooling systems that actively monitor and manage battery temperatures, limiting thermal runaway and reducing fire threats.

They also apply insulating materials to the battery pack, such as ceramic coatings or fire-resistant barriers, offering an extra line of defense against outside heat sources and reducing the likelihood of fire spreading during an event. China is making significant investments in the adoption of renewable energy sources, the geopolitical ramifications of doing so, and the formulation of new government regulations for foreign investment in the industry. For instance, the National Development and Reform Commission and the National Energy Administration jointly released the "14th Five-Year Plan for a Modern Energy System" in late March 2022, which sets objectives for China's energy industry up to 2025. The electrical system is anticipated to gain the resilience and adaptability it needs to absorb more renewable energy due to the new laws. Thereby, driving the market growth in the region.

Electric Vehicle Insulation Market: Competitive Analysis

The report provides a company market share analysis to give a broader overview of the key market players. In addition, the report also covers key strategic developments of the market, including acquisitions & mergers, new product launches, agreements, partnerships, collaborations & joint ventures, research & development, and regional expansion of major participants involved in the electric vehicle insulation market on a global and regional basis.

The global electric vehicle insulation market is dominated by players like:

- 3M

- CYG TEFA Co., Ltd.

- Armacell International S.A.

- Sika Automotive AG

- ADDEV Materials

- Sumitomo Riko Company Limited

- Adler Pelzer Holding GmbH

- INOAC Corporation

- Morgan Advanced Materials plc

- Pritex Limited

- Autoneum

- Tecman Speciality Materials Ltd

- Toyota Boshoku Corporation

- Zotefoams plc

- Unifrax

The global electric vehicle insulation market is segmented as follows;

By Product Type

- Thermal Interface Materials

- Ceramics

- Foamed Plastics

- Fiberglass

- Others

By Application

- Under the Hood & Battery Pack

- Interior

- Others

By Insulation Type

- Thermal

- Acoustic

- Electric

By Vehicle Type

- Battery Electric Vehicle (BEV)

- Plug-in Hybrid Electric Vehicle (PHEV)

- Hybrid Electric Vehicle (HEV)

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Insulation is used in electric vehicles to reduce the impact of heat, sound, and vibration on the vehicle and the occupants. The performance of the vehicle is impacted by overheating, which also causes motorized fluid to evaporate. The vehicle's chassis and hefty gears are also harmed by the shaking. Vehicle insulation prevents these damages from spreading, therefore extending the lifespan and performance of the vehicle and lowering maintenance costs. With these advantages, further electric car adoption is therefore anticipated to enhance product demand.

The electric vehicle insulation market expansion is anticipated to be driven by favorable government initiatives to encourage the usage of green cars. The industry will also be fueled by a rise in demand for battery-powered EVs, which is caused by strict government rules on car emissions.

According to a study, the global electric vehicle insulation market size was worth around USD 4.73 Billion in 2024 and is expected to reach USD 39.44 Billion by 2034.

The global electric vehicle insulation market is expected to grow at a CAGR of 21.4% during the forecast period.

Asia-Pacific is expected to dominate the electric vehicle insulation market over the forecast period.

Leading players in the global electric vehicle insulation market include 3M, CYG TEFA Co. Ltd., Armacell International S.A., Sika Automotive AG, ADDEV Materials, Sumitomo Riko Company Limited, Adler Pelzer Holding GmbH, INOAC Corporation, Morgan Advanced Materials plc, Pritex Limited, Autoneum, Tecman Speciality Materials Ltd, Toyota Boshoku Corporation, Zotefoams plc, Unifrax, among others.

The report explores crucial aspects of the electric vehicle insulation market, including a detailed discussion of existing growth factors and restraints, while also examining future growth opportunities and challenges that impact the market.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed