Global Waterproofing Membranes Market Size, Share, Growth Analysis Report - Forecast 2034

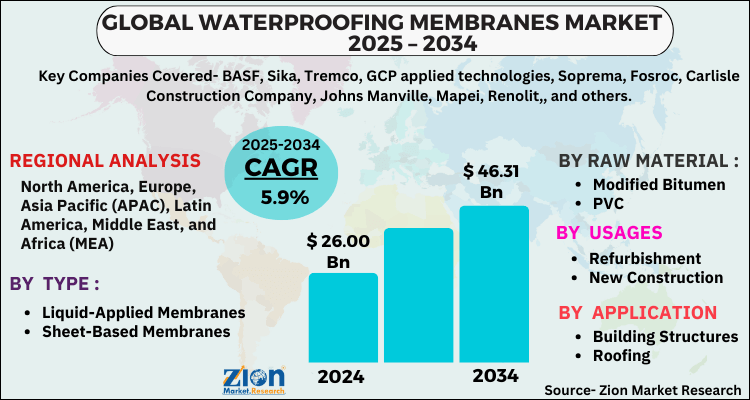

Waterproofing Membranes Market By Raw Material (Modified Bitumen, PVC, TPO, Acrylic, Polyurea, Polyurethane, And Others), By Type (Liquid-Applied Membranes and Sheet-Based Membranes), Usages (Refurbishment and New Construction), Application (Building Structures, Roofing, Walls, Roadways, Waste & Water Management, and Others), and By Region: Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

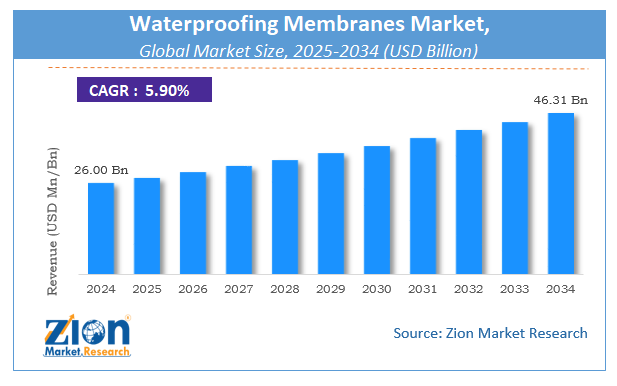

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 26.00 Billion | USD 46.31 Billion | 5.9% | 2024 |

Waterproofing Membranes Market: Industry Perspective:

The global waterproofing membranes market size was worth around USD 26.00 Billion in 2024 and is predicted to grow to around USD 46.31 Billion by 2034 with a compound annual growth rate (CAGR) of roughly 5.9% between 2025 and 2034. The report analyzes the global waterproofing membranes market's drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the waterproofing membranes industry.

Waterproofing Membranes Market: Overview

A waterproofing membrane is a fine layer of material that is put over another surface to prevent water from entering it. Waterproofing membranes might be adhesive or simply put on top of the substance to be protected. These waterproofing membranes can be manufactured with a variety of materials and come in a variety of sizes & thicknesses. Considering the applications these membranes can be utilized in several applications, including covering concrete as it is created to prevent water from affecting its structural integrity, and coating objects that are submerged where corrosion is a problem.

Key Insights

- As per the analysis shared by our research analyst, the global waterproofing membranes market is estimated to grow annually at a CAGR of around 5.9% over the forecast period (2025-2034).

- Regarding revenue, the global waterproofing membranes market size was valued at around USD 26.00 Billion in 2024 and is projected to reach USD 46.31 Billion by 2034.

- The waterproofing membranes market is projected to grow at a significant rate due to growing awareness of water conservation, increasing construction activities, rising demand for durable and moisture-resistant infrastructure, and advancements in membrane technologies.

- Based on Raw Material, the Modified Bitumen segment is expected to lead the global market.

- On the basis of Type, the Liquid-Applied Membranes segment is growing at a high rate and will continue to dominate the global market.

- Based on the Usages, the Refurbishment segment is projected to swipe the largest market share.

- By Application, the Building Structures segment is expected to dominate the global market.

- Based on region, Asia-Pacific is predicted to dominate the global market during the forecast period.

Waterproofing Membranes Market: Growth Drivers

Waterproofing Membranes Market: Infrastructural developments, rapid urbanization, and economic growth are likely to fuel market growth.

Infrastructure is how low- and middle-income nations are transformed into emerging or developing nations. Infrastructure expenditure is primarily driven by rapid urbanization in developing nations and sustained urbanization in industrialized economies. Infrastructural projects like power plants, electrical grids, water treatment & supply plants, highways, trains, airports, telecommunications networks, bridges, schools, and hospitals are all in high demand as a result of increased infrastructure investment. High-performance materials that are lightweight, strong, durable, high-performance, and adaptable are required by the building and construction sector. Because the quality and performance of construction materials must be exceedingly uniform, the demand for waterproofing membranes for infrastructure development is expanding.

Waterproofing Membranes Market: Restraints

Waterproofing Membranes Market: Notable issues with health and the environment may hamper the market growth.

The usage of waterproofing agents or membranes can be hazardous to the environment and human health. When employed in spray form, waterproofing membranes can be hazardous to the user as well as nearby personnel. These substances may include fluorinated substances, which can induce chemical pneumonitis, lung damage, and other respiratory disorders when they reach the respiratory system. Workers may also be exposed to hazardous vapors while using bitumen-based membranes. Long-term exposure to these chemicals can cause health problems including nasal inflammation and bronchitis. Additionally, people who have worked for a long time have had higher nasal and pharyngeal complaints. Although synthetic waterproofing membranes are becoming more popular, bitumen still has a considerable market share among several other waterproofing membranes.

Waterproofing Membranes Market: Opportunities

Waterproofing Membranes Market: Increasing interest in green roofs is likely to offer better growth opportunities for global market.

Toxicity and VOC levels are two drawbacks of waterproofing membranes. Manufacturers like Sika, Fosroc, and Tremco supply and have invested in R&D of solutions that have a low environmental effect. Manufacturers are progressively obtaining green certification for their materials to be used in energy-efficient buildings such as green roofs and green buildings. Green roofs reduce energy expenditures, the urban heat island effect, and stormwater runoff while also removing dangerous air pollutants. Green buildings, on the other hand, are structures that are both energy efficient and ecologically conscious throughout their lifespan. Waterproofing is vital for these structures because it protects them from water runoff and weather conditions while also increasing their energy efficiency.

Waterproofing Membranes Market: Challenges

Raw material price volatility is the major challenge for manufacturers

The majority of the basic ingredients required to make waterproofing membranes come from crude oil. PU, PVC, acrylic, and bitumen-based waterproofing membranes are all generated from petroleum. According to the BP Statistical Review of Energy, crude oil is one of the most significant sources of energy, accounting for 27.3 percent of worldwide primary energy consumption in 2015. From a low of USD 29.8 per barrel at the end of January 2016, the average crude oil spot price rose to USD 52 per barrel by the end of December 2016. Crude oil prices are on the mend and have steadied in the USD 55-60 per barrel area in 2017. Similarly, the current pandemic conditions also fluctuated the petroleum prices which directly affected the raw material prices.

Waterproofing Membranes Market: Segmentation

The global waterproofing membranes market is segmented based on Raw Material, Type, Usages, Application, and region.

Based on Raw Material, the global waterproofing membranes market is divided into Modified Bitumen, PVC, TPO, Acrylic, Polyurea, Polyurethane, And Others.

On the basis of Type, the global waterproofing membranes market is bifurcated into Liquid-Applied Membranes and Sheet-Based Membranes.

By Usages, the global waterproofing membranes market is split into Refurbishment and New Construction.

In terms of Application, the global waterproofing membranes market is categorized into Building Structures, Roofing, Walls, Roadways, Waste & Water Management, and Others.

Waterproofing Membranes Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Waterproofing Membranes Market |

| Market Size in 2024 | USD 26.00 Billion |

| Market Forecast in 2034 | USD 46.31 Billion |

| Growth Rate | CAGR of 5.9% |

| Number of Pages | 155 |

| Key Companies Covered | BASF, Sika, Tremco, GCP applied technologies, Soprema, Fosroc, Carlisle Construction Company, Johns Manville, Mapei, Renolit,, and others. |

| Segments Covered | By Raw Material, By Type, By Usages, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2020 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Waterproofing Membranes Market Regional landscape

In 2021, Asia Pacific dominated the global waterproofing membranes market, with a revenue share of more than 31 percent. The accelerated industrialization and expanding infrastructure advancements, particularly in India and China are to account for the expansion. Furthermore, the tendency would create city density, which will boost demand for utility and services in a home application for water requirements, resulting in market growth.

The waterproofing membranes market in North America is predicted to expand at a substantial rate throughout the forecast period, owing to increased building activity in Mexico and Canada. Furthermore, increased investment in warehouse development for the retail, healthcare, and automotive industries, all of which require waterproofing solutions, is boosting the market growth.

Recent Developments

- Sika opened a new production plant for the SikaProof structural waterproofing membrane in Sarnen, Switzerland, in March 2020. This expansion will increase manufacturing efficiency and allow the firm to service a fast-rising market.

- In April 2021, Tremco CPG APAC expands its roofing restoration portfolio with the addition of AlphaGuardTM BIO.

The global waterproofing membranes market is dominated by players like:

- BASF

- Sika

- Tremco

- GCP applied technologies

- Soprema

- Fosroc

- Carlisle Construction Company

- Johns Manville

- Mapei

- Renolit

The global waterproofing membranes market is segmented as follows:

By Raw Material

- Modified Bitumen

- PVC

- TPO

- Acrylic

- Polyurea

- Polyurethane

- And Others

By Type

- Liquid-Applied Membranes

- Sheet-Based Membranes

By Usages

- Refurbishment

- New Construction

By Application

- Building Structures

- Roofing

- Walls

- Roadways

- Waste & Water Management

- and Others

By Region

- North America

- The U.S.

- Canada

- Mexico

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Australia

- South Korea

- Rest of Asia Pacific

- The Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- Kuwait

- South Africa

- Rest of the Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

Table Of Content

Methodology

FrequentlyAsked Questions

Waterproofing membranes are protective layers applied to surfaces like roofs, walls, or foundations to prevent water infiltration. Made from materials such as bitumen, PVC, or rubber, they are commonly used in construction to protect buildings from moisture damage.

The global waterproofing membranes market is expected to grow due to increasing infrastructure development, growing demand for durable and long-lasting building materials, and rising awareness of the importance of preventing water damage in construction and industrial applications.

According to a study, the global waterproofing membranes market size was worth around USD 26.00 Billion in 2024 and is expected to reach USD 46.31 Billion by 2034.

The global waterproofing membranes market is expected to grow at a CAGR of 5.9% during the forecast period.

Asia-Pacific is expected to dominate the waterproofing membranes market over the forecast period.

Leading players in the global waterproofing membranes market include BASF, Sika, Tremco, GCP applied technologies, Soprema, Fosroc, Carlisle Construction Company, Johns Manville, Mapei, Renolit,, among others.

The report explores crucial aspects of the waterproofing membranes market, including a detailed discussion of existing growth factors and restraints, while also examining future growth opportunities and challenges that impact the market.

RelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed