Global Thermal Spray Coating Equipment Market Size, Share, Growth Analysis Report - Forecast 2034

Global Thermal Spray Coating Equipment Market By Material (Metals, Ceramics, Intermetallics, Polymers, Carbides, Abradables, Others), By Technology (Cold Spray, Flame Spray, Plasma Spray, HVOF, Electric Arc Spray, Others), By Application (Aerospace, Industrial Gas Turbine, Automotive, Medical, Printing, Oil & Gas, Steel, Pulp & Paper, Others), and By Region: Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 500.15 Million | USD 776.71 Million | 4.5% | 2024 |

Thermal Spray Coating Equipment Industry Perspective:

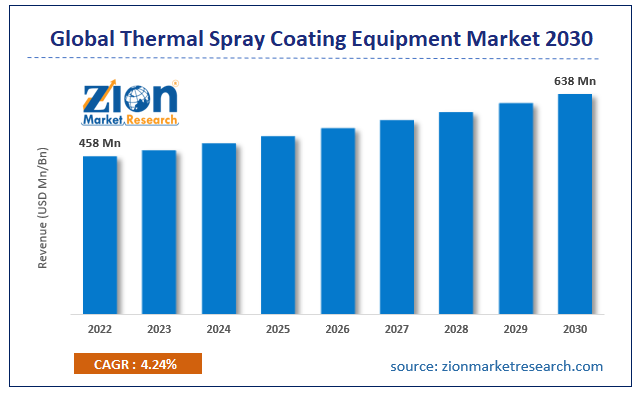

The global thermal spray coating equipment market size was worth around USD 500.15 Million in 2024 and is predicted to grow to around USD 776.71 Million by 2034 with a compound annual growth rate (CAGR) of roughly 4.5% between 2025 and 2034. The report analyzes the global thermal spray coating equipment market's drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the thermal spray coating equipment industry.

The report analyzes the global thermal spray coating equipment market’s drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the thermal spray coating equipment industry.

Thermal Spray Coating Equipment Market: Overview

Thermal spray coating equipment is used during the thermal spray coating process, which is performed on various substrates such as metal, ceramics, etc. Thermal spray coating processes are employed at high temperatures and velocities to coat a substrate with molten materials. These materials are melted by different methods, including, combustion & electric. Thermal spray coatings offer a wide range of favorable characteristics to the substrate such as corrosion resistance, environmental protection, thermal resistance, wear resistance, lubricity, and better electrical/thermal conductivity, among others.

Thermal spray coatings can improve a component's performance & increase its longevity. Some of the key equipment used are thermal spray coating systems, spray guns & nozzle, acoustical enclosures, feeders, dust collectors, spare parts, and others. The spray gun & nozzle are the main tools used during the thermal spray coating operation. These spray guns can be operated by a robot arm or manually. Arc spray, high-velocity oxy-fuel (HVOF), and plasma spray are among the key thermal spray coating systems used, across the globe.

Further, acoustical enclosures are used to contain noise produced by thermal spray operations, whereas dust collectors are used for collecting produced hazardous dust and fumes during the operations. The coating material is delivered to the spray gun by feeders in the form of wire or powder. Apart from these, various spare parts & other equipment are used to perform the thermal spray coating process.

Key Insights

- As per the analysis shared by our research analyst, the global thermal spray coating equipment market is estimated to grow annually at a CAGR of around 4.5% over the forecast period (2025-2034).

- Regarding revenue, the global thermal spray coating equipment market size was valued at around USD 500.15 Million in 2024 and is projected to reach USD 776.71 Million by 2034.

- The thermal spray coating equipment market is projected to grow at a significant rate due to rising demand from aerospace, automotive, and energy sectors, increasing need for corrosion and wear-resistant coatings, and advancements in coating technologies.

- Based on Material, the Metals segment is expected to lead the global market.

- On the basis of Technology, the Cold Spray segment is growing at a high rate and will continue to dominate the global market.

- Based on the Application, the Aerospace segment is projected to swipe the largest market share.

- Based on region, North America is predicted to dominate the global market during the forecast period.

Request Free Sample

Request Free Sample

Thermal Spray Coating Equipment Market: Growth Drivers

Increasing demand from the aerospace manufacturing industry to drive market growth during the forecast period.

The global thermal spray coating equipment market is projected to grow owing to the increasing applications of thermal spray coatings during aerospace parts & equipment manufacturing. Some of the key applications of thermal spray coatings in the aerospace industry are rotor-path linings, compressor seals, high-pressure turbine seals, bearings, fuel nozzles, landing gears, combustion liners, drive shafts, oil seals, and others. The need for thermal spray coatings has grown in the aerospace industry, as the industry seeks to lighten aircraft and increase fuel efficiency.

Thermal spray coatings protect aerospace metal parts from heat, abrasion, and corrosion. By applying metals, ceramics, and carbides utilizing arc, flame, plasma, or HVOF thermal spray coating systems, aerospace component life is greatly extended. Further, a rocket depends on its propulsion system to provide push both during takeoff and during changing velocity in space. In order to meet these requirements and increase component life in harsh operating environments, high nickel & refractory alloys are used for thermal spray coating materials. All these thermal spray-coating tasks are being performed by a set of different thermal spray-coating equipment such as coating systems, spray guns & nozzles, acoustical enclosures, feeders, dust collectors, etc.

For instance, according to the Global Market Forecast (GMF) released by AIRBUS, around 40,850 new passenger & freighter aircraft deliveries are expected to be made during 2023-2042, across the globe, out of which 32,630 units are likely to be single aisle, and 8,220 units are expected to be widebody. Moreover, the global demand for freighter aircraft is likely to reach 2,510 units during the period 2023-2042. The increasing demand for aircraft is expected to support the usage of thermal spray equipment at aerospace manufacturing facilities.

Moreover, according to the International Air Transport Association (IATA), commercial airline industry revenues are expected to reach USD 803 billion in 2023, up by 9.7% compared to the previous year’s revenue. In addition, the commercial airline industry’s net profits are likely to reach USD 9.8 billion in 2023, with a 1.2% net profit margin. These factors will increase the demand & procurement of thermal spray coatings equipment from the commercial aerospace industry.

Thermal Spray Coating Equipment Market: Restraints

Lack of precision & process consistency to restrict market expansion

In thermal spray technology, monitoring & improving process reliability are frequent issues. Determining the precision of thermal spray coating equipment is a quite hard task. Once the thermal spray coating has been applied, the effectiveness of the coatings is generally inspected through the visual method. It is very difficult to determine, how well the coating has been applied. The thermal spray process is a highly complex process with a wide range of interacting variables associated with the spray stream creation & its deposit formation on substrates. The manual operation of spray guns further decreases the precision & consistency in many cases such as the unavailability of skilled workers, etc. Moreover, it is hard to bond certain materials through thermal spray coating equipment. Such factors are expected to hinder the growth of the thermal spray coating equipment industry.

Thermal Spray Coating Equipment Market: Opportunities

Development of cold spray process technology to provide growth opportunities

The cold spray process is one of the recent technological developments in the thermal spraying field. The cold spray process offers various advantages, compared to the conventional methods, including, the spray material is not fused or melted during the process. The fundamental principle behind cold spray is that metal particles are propelled through a convergent-divergent nozzle at supersonic speed by a high-pressure stream. Thus, cold spray is a solid-state metal powder deposition method, which can be used for metal surface restoration. The technology can also be used for rapidly building thick coatings & thin films and can be employed for large-scale additive manufacturing at low temperatures. The process technology uses a spray gun, nozzle, powder feeder, and other equipment. Considering such factors, technology has promising opportunities in various sectors such as aerospace, oil & gas, power, marine, automotive, and other industries.

Thermal Spray Coating Equipment Market: Challenges

High cost of adoption to challenge market cap growth

A high initial cost is involved in setting up the thermal spray coating process systems, as these systems require very expensive apparatus. The spray gun & nozzle are among the costliest equipment in the overall system. The cost of the entire thermal spray coating system is significant as it is made up of various types of expensive equipment. However, the challenge from the cost factor can be mitigated, considering the growth prospects & high return in the thermal spray coating equipment industry.

Thermal Spray Coating Equipment Market: Segmentation

The global thermal spray coating equipment market is segmented based on equipment type, process, end-user industry, and region.

Based on equipment type, the global market segments are thermal spray coating systems, spray guns & nozzles, feeders, dust collectors, noise control enclosures, spare parts, and other thermal spray equipment. Currently, the global market is dominated by spray guns & nozzles, considering their high cost of purchase. A thermal spray gun is used to spray the melted or heated coating material onto the substrate such as metal surface or ceramics. Meanwhile, fuel is burned inside the combustion chamber of the nozzle to create a stream of combustion gases. OC Oerlikon Management AG, Kennametal Inc., and Saint-Gobain are among the key manufacturers of thermal spray guns for a wide range of applications.

Based on process, the thermal spray coating equipment industry is segmented into combustion and electric. The combustion segment dominated the market share in 2024. In the combustion spraying process, a gas stream is created by the chemical reaction of combustion fuel & oxygen, which heats the spray materials and propels them onto a substrate. Thereby, combustion spraying requires the following equipment, including, a combustion-based thermal spray coating system, spray gun & nozzle, feeder, spare parts, dust collector, and others.

Based on the end-user industry, the global market segments are aerospace & defense, automotive, electrical & electronics, oil & gas, energy & power, industrial gas turbines, steel making, medical devices, and other end-user industries. Currently, the thermal spray coating equipment industry is dominated by the aerospace & defense segment. Some of the key players in commercial aerospace are AIRBUS & Boeing. In 2024, Boeing delivered 774 commercial orders including 561 orders for the 737 family and 213 orders for twin-aisle airplanes. Whereas, AIRBUS delivered 661 commercial aircraft in 2022, registering a growth rate of around 8% compared to 2021.

Thereby, these deliveries correspond to the increasing demand for thermal spray coatings and hence, coating equipment at the respective manufacturing facilities. Further, according to the Stockholm International Peace Research Institute (SIPRI), military expenditure, across the globe, reached USD 2,240 billion in 2022, up by 3.7% compared to the previous year, thereby, increasing the demand for the thermal spray coating equipment industry.

Based on Material, the global thermal spray coating equipment market is divided into Metals, Ceramics, Intermetallics, Polymers, Carbides, Abradables, Others.

On the basis of Technology, the global thermal spray coating equipment market is bifurcated into Cold Spray, Flame Spray, Plasma Spray, HVOF, Electric Arc Spray, Others.

By Application, the global thermal spray coating equipment market is split into Aerospace, Industrial Gas Turbine, Automotive, Medical, Printing, Oil & Gas, Steel, Pulp & Paper, Othe

Global Thermal Spray Coating Equipment Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Global Thermal Spray Coating Equipment Market |

| Market Size in 2024 | USD 500.15 Million |

| Market Forecast in 2034 | USD 776.71 Million |

| Growth Rate | CAGR of 4.5% |

| Number of Pages | 230 |

| Key Companies Covered | Praxair Surface Technologies, Inc., Höganäs AB, H.C. Starck Inc., Castolin Eutectic, Wall Colmonoy Corp., Powder Alloy Corp., Saint-Gobain S.A., Carpenter Technology Corp., Fujimi Incorporated, Durum Verschleiss-Schutz GmbH, Montreal Carbide Co. Ltd, Kennametal Stellite, Oerlikon Metco, GTV Verschleißschutz GmbH (GTV Weat Protection GmbH), and others. |

| Segments Covered | By Material, By Technology, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2020 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Thermal Spray Coating Equipment Market: Regional Analysis

North America to lead the market during the forecast period

The global thermal spray coating equipment market growth is expected to be driven by North America, during the forecast period. Various end-user industries such as aerospace, automotive, oil & gas, energy & power, and electronics, among others, are the key consumers or procurers of thermal spray coating equipment. According to the Global Market Forecast (GMF) released by AIRBUS, around 6,970 new passenger & freighter aircraft deliveries are expected to be made during 2025-2034 in North America, out of which 83% units are likely to be a single aisle, and 17% units are expected to be widebody.

Furthermore, North America is significantly engaged in the production of automobiles, accounting for around 17.4% of total global production in 2024. In the automotive industry, thermal spray coatings are used to protect engine parts such as piston rings, turbochargers, and others. For instance, according to the International Organization of Motor Vehicle Manufacturers (OICA), in 2022, around 14,798,146 units of vehicles were produced in North America (incl. the United States, Mexico, & Canada), witnessing a growth rate of around 10% compared to the previous year. All such factors are supporting the growth of the thermal spray coating equipment industry.

The U.S. is among the key revenue generator for the thermal spray coating equipment industry in North America. The country has the presence of many petroleum refineries. In the petroleum refinery industry, thermal spray coating equipment is used to coat with metallic or ceramic materials and protect vessels, pipes, turbines, and others from wear, corrosion, etc. According to the Energy Information Administration (EIA), as of February 2022, the Motiva Enterprises refinery was the largest crude oil refinery based in Texas, the U.S., with a refining capacity of 607 thousand barrels per day. Some of the other major refineries in the U.S. are Marathon Petroleum, Exxon Mobil Corporation, and others.

Global Thermal Spray Coating Equipment Market: Competitive Analysis

The report provides a company market share analysis to give a broader overview of the key market players. In addition, the report also covers key strategic developments of the market, including acquisitions & mergers, new product launches, agreements, partnerships, collaborations & joint ventures, research & development, and regional expansion of major participants involved in the thermal spray coating equipment market on a global and regional basis.

The global thermal spray coating equipment market is dominated by players like:

- Praxair Surface Technologies Inc.

- Höganäs AB

- H.C. Starck Inc.

- Castolin Eutectic

- Wall Colmonoy Corp.

- Powder Alloy Corp.

- Saint-Gobain S.A.

- Carpenter Technology Corp.

- Fujimi Incorporated

- Durum Verschleiss-Schutz GmbH

- Montreal Carbide Co. Ltd

- Kennametal Stellite

- Oerlikon Metco

- GTV Verschleißschutz GmbH (GTV Weat Protection GmbH)

The global thermal spray coating equipment market is segmented as follows;

By Material

- Metals

- Ceramics

- Intermetallics

- Polymers

- Carbides

- Abradables

- Others

By Technology

- Cold Spray

- Flame Spray

- Plasma Spray

- HVOF

- Electric Arc Spray

- Others

By Application

- Aerospace

- Industrial Gas Turbine

- Automotive

- Medical

- Printing

- Oil & Gas

- Steel

- Pulp & Paper

- Others

By Region

- North America

- The U.S.

- Canada

- Mexico

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Australia

- South Korea

- Rest of Asia Pacific

- The Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- Kuwait

- South Africa

- Rest of the Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

Table Of Content

Methodology

FrequentlyAsked Questions

Thermal spray coating equipment is used during the thermal spray coating process, which is performed on various substrates such as metal, ceramics, etc. Some of the key equipment used are thermal spray coating systems, spray guns & nozzle, acoustical enclosures, feeders, dust collectors, spare parts, and others.

The global thermal spray coating equipment market is expected to grow due to increasing demand for enhanced surface properties in industries like aerospace, automotive, and energy, rising focus on extending component lifespan and reducing maintenance costs, and growing technological advancements leading to more efficient and autom.

According to a study, the global thermal spray coating equipment market size was worth around USD 500.15 Million in 2024 and is expected to reach USD 776.71 Million by 2034.

The global thermal spray coating equipment market is expected to grow at a CAGR of 4.5% during the forecast period.

The global thermal spray coating equipment market growth is expected to be driven by North America. It is currently the world’s highest revenue-generating market owing to the presence of a huge footprint of end-user industries such as aerospace, automotive, oil & gas, and others.

Leading players in the global thermal spray coating equipment market include Praxair Surface Technologies, Inc., Höganäs AB, H.C. Starck Inc., Castolin Eutectic, Wall Colmonoy Corp., Powder Alloy Corp., Saint-Gobain S.A., Carpenter Technology Corp., Fujimi Incorporated, Durum Verschleiss-Schutz GmbH, Montreal Carbide Co. Ltd, Kennametal Stellite, Oerlikon Metco, GTV Verschleißschutz GmbH (GTV Weat Protection GmbH), among others.

The report explores crucial aspects of the thermal spray coating equipment market, including a detailed discussion of existing growth factors and restraints, while also examining future growth opportunities and challenges that impact the market.

List of Contents

Thermal Spray Coating EquipmentIndustry Perspective: Thermal Spray Coating Equipment OverviewKey InsightsThermal Spray Coating Equipment Growth DriversThermal Spray Coating Equipment RestraintsThermal Spray Coating Equipment OpportunitiesThermal Spray Coating Equipment ChallengesThermal Spray Coating Equipment SegmentationGlobalReport Scope Thermal Spray Coating Equipment Regional AnalysisGlobalCompetitive AnalysisHappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed