Global Metal Injection Molding (MIM) Market Size, Share, Growth Analysis Report - Forecast 2034

Metal Injection Molding (MIM) Market By End Use (Automotive, Consumer product, Medical, Industrial, Defense, Others), By End-User (Electronics, Automotive, Sporting Goods, Power Tools, Defense & Firearms, Medical & Dental, Aerospace, IT & Telecommunications, Oil Exploration, Consumer Goods, Others), and By Region: Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

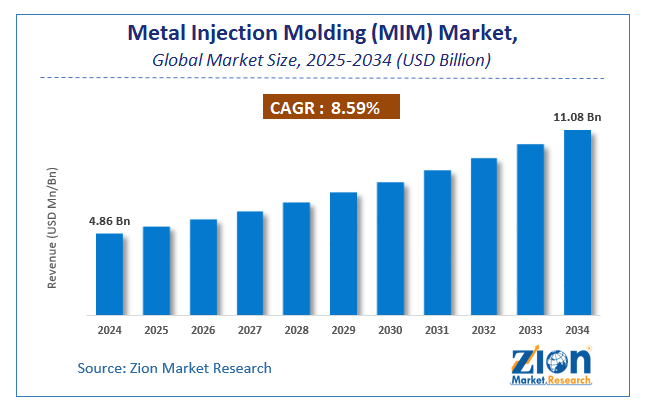

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 4.86 Billion | USD 11.08 Billion | 8.59% | 2024 |

Metal Injection Molding (MIM) Market: Industry Perspective

The global metal injection molding (MIM) market size was worth around USD 4.86 Billion in 2024 and is predicted to grow to around USD 11.08 Billion by 2034 with a compound annual growth rate (CAGR) of roughly 8.59% between 2025 and 2034.

The report analyzes the global metal injection molding (MIM) market's drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the metal injection molding (MIM) industry.

The report delves deeper into several crucial aspects of the global metal injection molding (MIM) industry. It includes a detailed discussion of existing growth factors and restraints. Future growth opportunities and challenges that impact the metal injection molding (MIM) market are comprehensively addressed in the report.

Metal Injection Molding (MIM) Market: Overview

Metal injection molding (MIM) is an important and common manufacturing process that works by combining the principles of plastic injection molding and powdered metallurgy. The process results in the production of complex metal parts. Out of all the other manufacturing options in sectors that deal with heavy metals, MIM is one of the most cost-effective methods used for the mass production of small yet intricate components. Moreover, this process also delivers consistency and precision. At the start of the MIM process, manufacturers first blend fine metal powders, typically consisting of stainless steel, titanium, or copper, with a thermoplastic binder material.

Key Insights

- As per the analysis shared by our research analyst, the global metal injection molding (MIM) market is estimated to grow annually at a CAGR of around 8.59% over the forecast period (2025-2034).

- Regarding revenue, the global metal injection molding (MIM) market size was valued at around USD 4.86 Billion in 2024 and is projected to reach USD 11.08 Billion by 2034.

- The metal injection molding (MIM) market is projected to grow at a significant rate due to growing demand for complex, high-precision components in automotive, medical, and aerospace industries, alongside cost-efficiency and material versatility advantages.

- Based on End Use, the Automotive segment is expected to lead the global market.

- On the basis of End-User, the Electronics segment is growing at a high rate and will continue to dominate the global market.

- Based on region, North America is predicted to dominate the global market during the forecast period.

Request Free Sample

Request Free Sample

Metal Injection Molding (MIM) Market: Growth Drivers

High cost-effectiveness of the MIM process to drive market growth

The global metal injection molding (MIM) market is projected to grow owing to the higher cost-effectiveness that this process offers when compared to other manufacturing processes such as machining or investment casting. The primary reasons for lower expenses associated with MIM are reduced waste and labor. Since MIM is highly automated, it greatly reduces extreme dependency on manual labor. This translates to more labor savings, especially in high-volume production processes. The MIM method generates less scrap which means less volume of products that have to be discarded. Moreover, metal injection molding is highly precise in terms of output. In most cases, manufacturers do not have to invest in deploying secondary operations such as assembly or finishing. Such factors that work in favor of adopting the MIM process could result in higher demand for this method in the coming years.

Metal Injection Molding (MIM) Market: Restraints

High starting cost for MIM tools to restrict market expansion

The global sales volume of the metal injection molding industry may be restricted during the forecast period owing to the high cost associated with setting up MIM sites due to the expense related to tooling systems used in this method. It requires specialized equipment which includes a debinding oven, injection molding machine, and a sintering furnace. All of these pieces of equipment are costly which could be an added burden for companies just starting out in the sector. Moreover, businesses may find that working with already established MIM manufacturers may be more profitable which further discourages the entry of new players.

Metal Injection Molding (MIM) Market: Opportunities

Growing application of the MIM process in healthcare to provide growth opportunities

The global metal injection molding market is expected to witness higher growth avenues owing to the increasing application of the MIM process in one of the fastest-growing industries which is the healthcare sector. Factors such as the rising number of medical patients, surging accident rates, increased demand for quality medical care, and growing healthcare expenditure along with other reasons have resulted in greater demand for advanced, specialized healthcare and medicinal equipment. This provides an excellent opportunity for MIM processors to explore producing orthopedic implants, dental components, and other medical devices.

Metal Injection Molding (MIM) Market: Challenges

Fluctuating prices of raw materials to challenge market growth

Metal injection molding used two primary raw materials including a combination of metal powders and binders. The former is a mixture of fine particles of various metals or metal alloys while the latter are organic materials that facilitate the molding process. The price of these products may be influenced by factors including energy & production costs, global market conditions, supply & demand dynamics, and the availability or sourcing of raw materials. This poses a major challenge for the metal injection molding market players due to the association of MIM with multiple variables.

Metal Injection Molding (MIM) Market: Segmentation

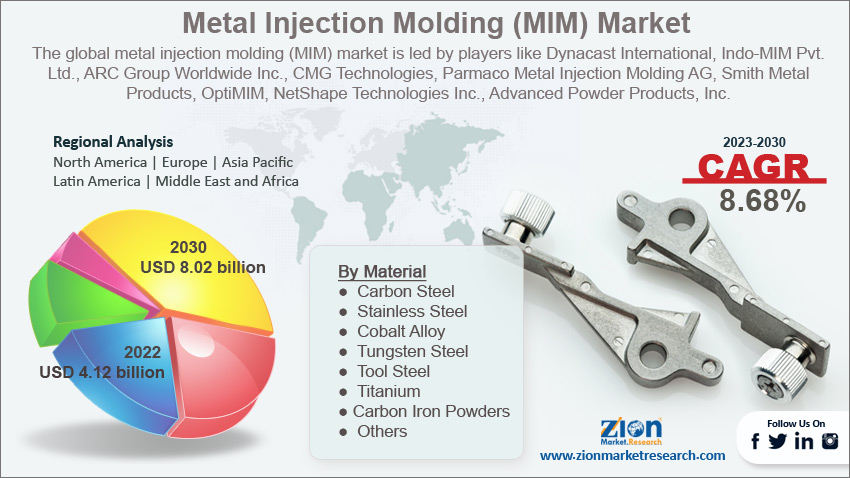

The global metal injection molding (MIM) market is segmented based on end-user, material, and region.

Based on end-user, the global market is segmented into electronics, automotive, sporting goods, power tools, defense & firearms, medical & dental, aerospace, IT & telecommunications, oil exploration, consumer goods, and others. The industry registered the highest growth in the electronic segment in 2022 as the metal injection molding process is used extensively to manufacture a wide range of components such as connectors, terminals, switches, and sensor housings. With the growing requirement and consumption of complex but miniaturized parts, the MIM manufacturing process has also gained momentum. However, other industries are also significant revenue generators. In the automotive sector, MIM is used during the production of engine parts, transmission components, fuel system parts, and sensors among other components. A recent study by IPC Org concluded that the electronic sector is responsible for nearly 1.3 million jobs in the US.

Based on material, the metal injection molding industry is divided into carbon steel, stainless steel, cobalt alloy, tungsten steel, tool steel, titanium, carbon iron powders, and others. The highest CAGR was observed in the stainless steel segment driven by the wide-scale applications of the material. It offers excellent corrosion resistance, high strength, and good ductility which makes it suitable for multiple purposes. The versatility of stainless steel is what makes it one of the most preferred choices of materials across automotive, electronics, medical, aerospace, and consumer goods segments. Stainless steel alloys including 316L or 17-4PH will continue the growth trajectory during the forecast period. Tools steels such as H13 or M2 are used when high hardness, heat resistance, and wear resistance are important determining criteria.

Metal Injection Molding (MIM) Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Metal Injection Molding (MIM) Market |

| Market Size in 2024 | USD 4.86 Billion |

| Market Forecast in 2034 | USD 11.08 Billion |

| Growth Rate | CAGR of 8.59% |

| Number of Pages | 332 |

| Key Companies Covered | Dynacast, GKN Automotive Limited, Greene Group Industries, Inc. (Britt Manufacturing), Optimim, Dean Group International, Sintex, CMG Technologies, INDO-MIM, Schunk Mobility, Rockleigh Industries, and others. |

| Segments Covered | By End Use, By End-User, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2020 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Recent Developments:

- In June 2023, TriTech Titanium Parts LLC based out of Detroit, Michigan, and Tekna Holding ASA, a Canadian market leader, announced strategic collaboration. Joint efforts by both companies resulted in successful Binder Jetting of titanium parts with the use of a Desktop Metal P1 Additive Manufacturing machine. Titanium powder provider by Tekna compliments the binder jet 3D printing capabilities of TriTech

- In June 2023, Ceratizit, part of the CERATIZIT Group which is a manufacturer of hard material products used for wear protection and cutting tools, announced that since the start of the year, the company has ensured production operations are conducted using 99% renewable energy sources. The company plans to become carbon-neutral by the end of 2025

Metal Injection Molding (MIM) Market: Regional Analysis

North America to become the leading revenue generator in the market

The global metal injection molding (MIM) market is expected to be dominated by North America particularly the US and the Canadian regions. One of the primary reasons for higher growth is the growing acceptance and use of the MIM method in the electronics sector where it is being used to produce small and complex intricate components. Moreover, the presence of key industry players and growing strategic measures adopted by them with allying countries could result in higher revenue.

Europe is projected to be driven by increasing demand for MIM-produced automotive components. The increasing investment in electric vehicles and the aerospace sector may deliver a better growth avenue. The region has one of the most strict quality standards and advanced manufacturing capabilities which directly aligns with the offerings of the MIM method. The presence of manufacturers and collaborations between research institutions and industries contribute to higher growth in Europe.

Metal Injection Molding (MIM) Market: Competitive Analysis

The report provides a company market share analysis to give a broader overview of the key market players. In addition, the report also covers key strategic developments of the market, including acquisitions & mergers, new product launches, agreements, partnerships, collaborations & joint ventures, research & development, and regional expansion of major participants involved in the metal injection molding (MIM) market on a global and regional basis.

The global metal injection molding (MIM) market is dominated by players like:

- Dynacast

- GKN Automotive Limited

- Greene Group Industries Inc

- (Britt Manufacturing)

- Optimim

- Dean Group International

- Sintex

- CMG Technologies

- INDO-MIM

- Schunk Mobility

- Rockleigh Industries

The global metal injection molding (MIM) market is segmented as follows;

By End Use

- Automotive

- Consumer product

- Medical

- Industrial

- Defense

- Others

By End-User

- Electronics

- Automotive

- Sporting Goods

- Power Tools

- Defense & Firearms

- Medical & Dental

- Aerospace

- IT & Telecommunications

- Oil Exploration

- Consumer Goods

- Others

By Region

- North America

- The U.S.

- Canada

- Mexico

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Australia

- South Korea

- Rest of Asia Pacific

- The Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- Kuwait

- South Africa

- Rest of the Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

Table Of Content

Methodology

FrequentlyAsked Questions

RelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed