In-Pipe Inspection Robots Market Size, Share, Trends, Growth and Forecast 2032

In-Pipe Inspection Robots Market by Product Type (Thickness Measuring Robot, Diameter Robot, Welding Pipe Robot, and Others), by Application (Water Supply Facilities, Oil Pipeline, Gas Pipeline, and Plant) - Global Industry Analysis, Size, Share, Growth, Trends, and Forecast 2024 - 2032

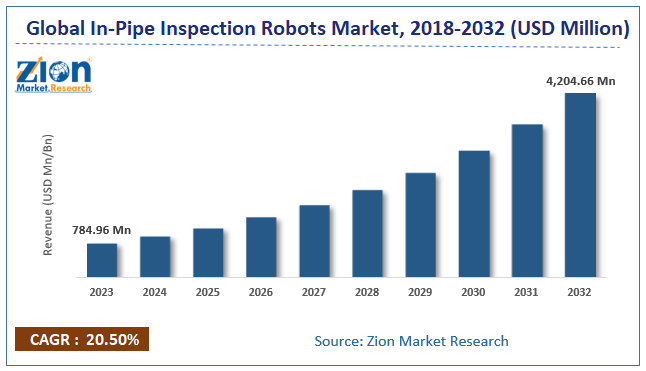

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 784.96 Million | USD 4,204.66 Million | 20.50% | 2023 |

The global In-Pipe Inspection Robots Market size was worth around USD 784.96 Million in 2023 and is predicted to grow to around USD 4,204.66 Million by 2032 with a compound annual growth rate (CAGR) of roughly 20.50% between 2024 and 2032.

Market Overview

Robots are often developed to replace human labor in demanding and dangerous workplaces. The robots are also used to explore hot-weather locales and remote workplaces. Additionally, because pipelines carry dangerous chemicals and fluids and have a small interior diameter that prevents humans from accessing them, robots are utilized to inspect pipes. Due to the intricate internal structure of pipes and the hazardous compounds they contain, robotic inspection, measurement of the rust proportion in pipes, sludge sample, and development of scale on the internal pipe surface are needed. Robots used for in-pipe inspection are useful for analyzing the debris produced inside the pipe. These robots communicate with the in-pipe inspection robot's controller via video answers sent from the ground.

Customers can assess the true state of the pipe and gauge the depth of encrustation on its walls through this. These robots are designed to function in environments requiring extreme skill and can operate in hazardous environments. This is one of the main drivers propelling the market for in-pipe inspection robots. Since the pipeline is constrained by numerous environmental conditions that restrict the aspect of examination inside them, it is thought to be a good methodology to inspect using in-pipe inspection robots.

Report Brief

- The report covers forecast and analysis for the in-pipe inspection robots market on a global and regional level.

- The report includes the positive and negative factors that are influencing the growth of the market.

- Market opportunities are discussed in detail in the report.

- The revenue generated by the prominent industry players has been analyzed in the report.

- The market numbers have been calculated using top-down and the bottom-up approaches.

- The in-pipe inspection robots market has been analyzed using Porter’s Five Forces Analysis.

- The market is segmented on the basis of product type, application, and organization size which in turn is bifurcated on a regional level as well.

- All the segments have been evaluated based on the present and the future trends.

- The report deals with the in-depth quantitative and qualitative analyses of the in-pipe inspection robots market.

- The report includes the detailed company profiles of the prominent market players.

Market Summary

Overview

Robots that are meant for inspecting the residues that are built up inside the pipe are known as in-pipe inspection robots. Such robots have the capability to send video feedbacks from the ground to the controller of the robot. By this, the users can verify the actual condition of the pipe and can also measure the thickness of the deposition on the walls of the pipe. In-pipe inspection robots have applications in water supply facilities, oil refineries, gas fields, and processing units, and several manufacturing plants.

Drivers and Restraints

Robots are being used increasingly in various verticals in order to reduce human intervention from work environments that are dangerous. In various industrial plants, the pipeline networks are inspected regularly for efficiency and security. The operations such as cleaning, maintenance, and inspection are expensive thus applications of robots appear to be an attractive solution. Pipeline networks are laid down for the transportation of oil and gas, drinking waters, etc. These pipelines face the problem of corrosion, aging, cracks, and various another type of damages. Thus keeping a check on these pipeline networks is very essential. Manual inspection of pipelines requires a lot of manpower. This incurs additional cost for the companies. Usage of in-pipe inspection robots, though expensive, works with accuracy and generates positive cash flow over a period of time. This is likely to boost the use of in-pipe inspection robots market over the forecast period. Moreover, the petrochemical industry is increasingly adopting pipeline transport. As the demand for oil and gas is increasing across the globe, it is expected that the pipeline network will increase in length in the near future thereby increasing the popularity of the in-pipe inspection robots market.

However, the in-pipe inspection robots market is expected to face some challenges such as high capital investment and inability to move in T-shape pipe. This is projected to negatively impact the in-pipe inspection robots over the forecast period.

Global In-Pipe Inspection Robots Market: Segmentation

Diameter robot product type segment registered the highest market share of over 37.09% in 2017 and it is also expected to grow at a high CAGR of around 17.62% over the forecast period. Diameter robots are capable of moving through very small pipes. This robot can be used to inspect and perform operations in various sizes of pipes ranging from 150 mm to 5000 mm. Hence diameter robots are being widely used in several applications and are projected to grow at a significant CAGR over the forecast period. In the coming years, welding pipe robot is expected to grow with the highest CAGR of over 18%. This is owing to the fact that automation has stepped in as an alternative to manual welding. Robotic automation along with the flexibility of the human operator anticipates increasing the demand for the welding pipe robot.

By application, gas pipelines accounted for the largest market share of 37.22% in 2023. The gas pipeline application was valued at USD 225.75 million in the year 2023 and is expected to reach over USD 881.29 million by the end of 2032 growing at a CAGR of 16.39% between 2023 and 2032. The growth in the usage of in-pipe inspection robots in the gas pipeline application is mainly due to the deposition of a wax-like substance on the walls of the pipelines. Such deposition occurs very often owing to change in the pipeline wall temperature. Moreover, the negative radial temperature gradient present in the flow may also result in deposition of a crystalline or wax-like substance on the walls of the pipeline. The deposition on the walls of the pipelines is more frequent in gas pipelines. Hence in-pipe inspection robots are widely used in the inspection of gas pipelines.

Asia Pacific is expected to grow at the highest CAGR of 20.23% over the forecast period. The growth in Asia Pacific in-pipe inspection robots market is owing to increasing investment in the transportation of petrochemical products through the pipeline network. This is estimated to create ample opportunities for in-pipe inspection robots in the Asia Pacific. North America held the highest market share of the global in-pipe inspection robots market in 2017. This is owing to the large network of pipeline in North America which accounts for around 2,325,032 km.

In-Pipe Inspection Robots Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | In-Pipe Inspection Robots Market Size Report |

| Market Size in 2023 | USD 784.96 Million |

| Market Forecast in 2032 | USD 4,204.66 Million |

| Growth Rate | CAGR of 20.50% |

| Number of Pages | 188 |

| Forecast Units | Value (USD Billion), and Volume (Units) |

| Key Companies Covered | CUES Inc., Envirosight LLC, GE Inspection Robotics, IBAK Helmut Hunger GmbH & Co. KG., Medit Inc. (Fiberscope), RedZone Robotics, Inc., Inuktun Services Ltd., MISTRAS Group Inc., RIEZLER Inspektions Systeme GmbH & Co. KG, Xylem, Inc., and Honeybee Robotics, Ltd., among others. |

| Segments Covered | By Product Type ,By Technology, By end-user, and By region |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

The key players in the global Industrial Automation Market are -

The report includes detailed profiles of the prominent market players that are trending in the market. The lists of the players that are compiled in the report are -

- CUES Inc.

- Envirosight LLC

- GE Inspection Robotics

- IBAK Helmut Hunger GmbH & Co. KG.

- Medit Inc. (Fiberscope)

- RedZone Robotics

- Inuktun Services Ltd.

- MISTRAS Group Inc.

- RIEZLER Inspektions Systeme GmbH & Co. KG

- Xylem

- Honeybee Robotics

- among others.

The prominent market players maintain the competitive edge in the global market by making investments in the mergers and acquisitions and by increasing their product portfolio. On 11th December 2017, Xylem Inc. acquired Calgary-based water and oil and gas pipeline monitoring specialist Pure Technologies Ltd. for $509 million.

Global In-Pipe Inspection Robots Market: Product Type Segment Analysis

- Thickness Measuring Robot

- Diameter Robot

- Welding Pipe Robot

- Others

Global In-Pipe Inspection Robots Market: Application Segment Analysis

- Water Supply Facilities

- Oil Pipeline

- Gas Pipeline

- Plant

Global In-Pipe Inspection Robots Market: Regional Segment Analysis

- North America

- The U.S.

- Europe

- UK

- France

- Germany

- Asia Pacific

- China

- Japan

- India

- Latin America

- Brazil

- The Middle East and Africa

Table Of Content

Methodology

FrequentlyAsked Questions

The global In-Pipe Inspection Robots Market size was worth around USD 784.96 Million in 2023 and is predicted to grow to around USD 4,204.66 Million by 2032 with a

compound annual growth rate (CAGR) of roughly 20.50% between 2024 and 2032.

The largest share of the In-Pipe Inspection Robots Market is held by Asia Pacific. Developing countries of Asia Pacific such as China, Japan, and India will be dominating the market scenario mainly due to the rising constructional activities. The growth of Asia-Pacific region is expected to be followed by the Middle East and North America. Also, significant growth is expected from Western Europe owing to the developments taking place in this region especially in countries such as Italy, Germany, the U.K, France, and Spain. However, growth in Africa, Latin America, and Eastern Europe is anticipated to be moderate over the forecast period.

CUES Inc., Envirosight LLC, GE Inspection Robotics, IBAK Helmut Hunger GmbH & Co. KG., Medit Inc. (Fiberscope), RedZone Robotics, Inc., Inuktun Services Ltd., MISTRAS Group Inc., RIEZLER Inspektions Systeme GmbH & Co. KG, Xylem, Inc., and Honeybee Robotics, Ltd., among others.

RelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed