Fumed Silica and Precipitated Silica Market Size, Share Report 2034

Fumed Silica and Precipitated Silica Market By Product Form (Powdered Precipitated Silica, Granulated Precipitated Silica), By Application (Paints and Coatings, Polymers and Plastics, Medications and Healthcare), By End-Use Industry (Tire Manufacturing, Rubber Goods, Personal Care and Cosmetics, Food and Feed Additives), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

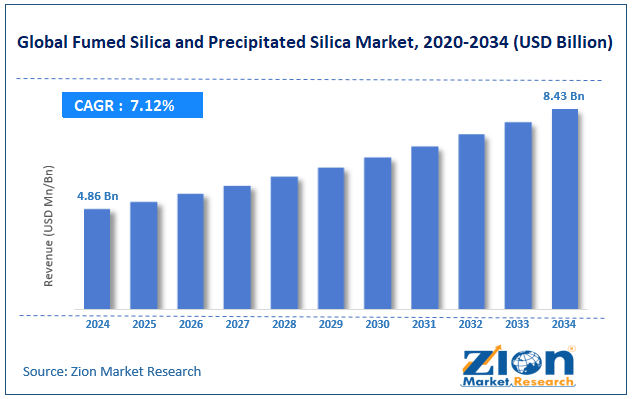

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 4.86 Billion | USD 8.43 Billion | 7.12% | 2024 |

Fumed Silica and Precipitated Silica Industry Perspective:

What will be the size of the global fumed silica and precipitated silica market during the forecast period?

The global fumed silica and precipitated silica market size was around USD 4.86 billion in 2024 and is projected to reach USD 8.43 billion by 2034, with a compound annual growth rate (CAGR) of roughly 7.12% between 2025 and 2034.

Key Insights:

- As per the analysis shared by our research analyst, the global fumed silica and precipitated silica market is estimated to grow annually at a CAGR of around 7.12% over the forecast period (2025-2034)

- In terms of revenue, the global fumed silica and precipitated silica market size was valued at around USD 4.86 billion in 2024 and is projected to reach USD 8.43 billion by 2034.

- The fumed silica and precipitated silica market is projected to grow significantly owing to increasing use in paints and coatings, expansion of the adhesives and sealants market, and rising demand from the food and beverage industry.

- Based on product form, the powdered precipitated silica segment is expected to lead the market, while the granulated precipitated silica segment is expected to grow considerably.

- Based on application, the paints and coatings segment is the largest, while the polymers and plastics segment is projected to record sizeable revenue over the forecast period.

- Based on end-use industry, the tire manufacturing segment is expected to lead the market, followed by the rubber goods segment.

- By region, Asia Pacific is projected to dominate the global market during the forecast period, followed by North America.

Fumed Silica and Precipitated Silica Market: Overview

Fumed silica and precipitated silica are the types of silicon dioxide used as anti-caking agents, thickeners, and fillers. Fumed silica, made via flame hydrolysis, is extremely light with a high surface area, while precipitated silica, made by acidifying silicates, holds a granular structure and is widely used in toothpaste, rubber, and food products. The global fumed silica and precipitated silica market is projected to witness substantial growth driven by rising demand in the tire and rubber industries, expanding personal care and cosmetics use, and growth in the food and pharmaceutical sectors. Growth in automotive production drives the demand for silica as a strengthening filler to enhance tire performance, fuel efficiency, and wear resistance. Fumed and precipitated silica improve mechanical properties, fueling their adoption in tire compounds.

Moreover, silica’s oil-absorption and texture-enhancing properties make it suitable for powders, cosmetics, sunscreens, and lotions. Growing global beauty and skincare consumption augments industry demand. Furthermore, as an anti-caking and flow-aiding agent, precipitated silica promotes product consistency in powdered supplements and foods. Stringent quality requirements in pharma formulations maintain long-term use.

Although drivers exist, the global market is challenged by factors such as price volatility in raw materials and high production costs for fumed silica. Silicon feedstocks and energy costs vary, impacting the total cost of silica production. This unpredictability creates challenges for manufacturers in setting stable pricing strategies. Price volatility may also affect suppliers' profitability and deter new entrants. Similarly, the flame hydrolysis process used to make fumed silica requires significant capital investment and is energy-intensive. These high production costs lower the ability of smaller players to compete effectively. Subsequently, only well-capitalized manufacturers can sustain large-scale production.

Even so, the global fumed silica and precipitated silica industry is well-positioned due to advancements in nanosilica and specialty grades, as well as sustainable product development. Improvements in nano-silica and specialty formulations enable manufacturers to create products with enhanced performance. Applications in high-performance composites, electronics, and coatings offer a high-value market. This advancement-driven approach may distinguish suppliers and capture premium segments. Low-carbon and green production techniques for silica are gaining prominence as companies focus on sustainability. Environmentally-friendly and bio-based variants attract eco-conscious consumers and regulatory bodies. Sustainability initiatives offer differentiation and a competitive advantage in the global market.

Fumed Silica and Precipitated Silica Market: Dynamics

Growth Drivers

How does the cosmetics & personal care market drive the fumed silica and precipitated silica market?

Fumed silica is valued in skincare and cosmetics for oil absorption, texture improvement, and thickening. Growing disposable incomes and the rise of online retail in North America and Asia are driving demand for premium personal care and grooming products. Applications comprise toothpaste, lotions, and deodorants, registering for 20% of precipitated silica use. Trends in multifunctional and clean-label products further strengthen adoption. Its non-toxic and inert nature supports user safety preferences. These factors together drive the fumed silica and precipitated silica market.

How are sustainability & eco-friendly trends driving the fumed silica and precipitated silica market?

Silica is environmentally friendly, energy-efficient, and more inert than traditional fillers. Regulations on VOC emissions, carbon footprint, and fuel efficiency are pushing industries toward silica-based alternatives, particularly in coatings, tires, and sealants. Manufacturers are steadily adopting recyclable and low-impact formulations to meet sustainability standards. Silica supports companies in achieving regulatory compliance while complying with green initiatives.

Restraints

Raw material supply volatility adversely impacts the market progress

The availability and pricing of major raw materials like silicon tetrachloride, sulfuric acid, and sodium silicate vary due to geopolitical tensions, logistical challenges, and mining restrictions. Supply scarcity can delay production and raise costs, squeezing margins. Reliance on a low number of suppliers escalates operational risk. Long lead times for raw materials complicate inventory and production planning. Such volatility hinders manufacturers' ability to plan large-scale expansions effectively. Industry growth may be affected if supply chain disruptions persist.

Opportunities

How is the expansion in specialty & high-performance applications advantageous for the growth of the Fumed Silica and Precipitated Silica Market?

Silica with controlled particle size, surface chemistry, and porosity unveils advanced uses in adhesives, electronics, composites, and high-performance polymers. These segments grow faster than traditional fillers because of performance-driven demand. High-value applications allow better margins and differentiation for producers. Continuous research and development of specialty grades expand their applicability in niche markets. Market participants who advance can capture premium demand. Specialty applications are a leading driver of long-term growth in the fumed silica and precipitated silica industry.

Challenges

Safety & handling challenges restrict the market growth

Ultrafine fumed silica is prone to airborne dispersion, offering inhalation risks and possible fire hazards. Safe transport, storage, and handling need specialized infrastructure and operational protocols. Compliance with workplace safety regulations adds operational complexity and costs. Safety considerations may hamper adoption in less-regulated or small-scale facilities. Monitoring and training systems should be maintained consistently. This challenge imposes operational pressure on end users and manufacturers alike.

Fumed Silica and Precipitated Silica Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Fumed Silica and Precipitated Silica Market |

| Market Size in 2024 | USD 4.86 Billion |

| Market Forecast in 2034 | USD 8.43 Bllion |

| Growth Rate | CAGR of 7.12% |

| Number of Pages | 221 |

| Key Companies Covered | Evonik Industries AG, Cabot Corporation, Wacker Chemie AG, Solvay SA, PPG Industries Inc., Tokuyama Corporation, Oriental Silicas Corporation, OCI Company Ltd., Quechen Silicon Chemical Co. Ltd., Zhuzhou Xinglong New Materials, Wuxi Hengcheng Silicon Industry Co. Ltd., Sanming Fengrun Chemical Industry Co. Ltd., Shandong Link Science and Technology Co. Ltd., Fujian Yuanxiang New Materials Co. Ltd., Huber Engineered Materials, and others. |

| Segments Covered | By Product Form, By Application, By End-Use Industry, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Fumed Silica and Precipitated Silica Market: Segmentation

The global fumed silica and precipitated silica market is segmented based on product form, application, end-use industry, and region.

Why is the Powdered Precipitated Silica segment projected to dominate the fumed silica and precipitated silica market?

Based on product form, the global fumed silica and precipitated silica industry is divided into powdered precipitated silica and granulated precipitated silica. The powdered precipitated silica segment dominates, accounting for nearly 60% of the market. It is widely used in coatings, rubber, personal care, and adhesives due to its versatility and ease of blending.

Conversely, the granulated precipitated silica segment ranks second with 58% market share. It is largely used for ease of handling and reduced dust generation.

What factors help the Paints & Coatings segment lead the fumed silica and precipitated silica market?

Based on application, the global fumed silica and precipitated silica market is segmented into paints and coatings, polymers and plastics, and medications and healthcare. The paints & coatings segment leads with 35% of the total market. This growth is backed by the surging use of both precipitated and fumed silica to prevent sagging, control rheology, and enhance durability in industrial, architectural, and automotive coatings.

Nonetheless, the polymers and plastics segment ranks second, accounting for 15% of the total market share. Silica fillers improve mechanical strength, processability, and thermal stability in engineering plastics and composites. This makes the application widely adopted in consumer goods, automotive, and industrial components, ranking it ahead of healthcare in overall market share.

What are the key reasons for the leadership of the Tire Manufacturing segment in the fumed silica and precipitated silica market?

Based on end-use industry, the global market is segmented into tire manufacturing, rubber goods, personal care and cosmetics, and food and feed additives. The tire manufacturing segment captures nearly 35% of the total market. This is backed by broad use in high-performance, fuel-efficient tires, where silica improves wet grip, rolling resistance, and wear resistance. This segment’s dominance stems from sustained automotive production and the inclination towards ‘green’ tires in the key market.

However, the rubber goods segment holds the second-largest share at 25% of the total market. This is supported by the widespread use of silica for reinforcement and performance improvement across various rubber components.

Fumed Silica and Precipitated Silica Market: Regional Analysis

What enables Asia Pacific's strong foothold in the global Fumed Silica and Precipitated Silica Market?

Asia Pacific is likely to sustain its leadership in the fumed silica and precipitated silica market, with a 7.1% CAGR, driven by rapid urbanization and industrialization, a strong tire manufacturing and automotive base, and a growing personal care and pharmaceutical market. APAC’s fast-growing construction, manufacturing, and automotive sectors fuel high demand for rubber, coatings, and plastics that use precipitated and fumed silica. The growth of infrastructure and urban development directly drives silica consumption across numerous industries. Economies like Japan, China, and India have large tire and automotive production industries, in which silica is a vital filler for fuel efficiency and performance. Growing vehicle sales and green initiatives sustain the industry's continuous growth.

Furthermore, rising disposable incomes and lifestyle-driven demand are increasing demand for skincare, cosmetics, and pharmaceutical products that incorporate silica for anti-caking and texture modification. The growing consumer base offers a stable end-use market.

Why does North America rank second in the global Fumed Silica and Precipitated Silica Market?

North America continues to hold the second-highest share, with a 6.4% CAGR in the fumed silica and precipitated silica industry, driven by advanced automotive and tire industries, a developed paints and coatings market, and a strong pharmaceutical and healthcare industry. North America has a well-developed tire manufacturing and automotive sector that demands high-performance silica for durable, fuel-efficient tires. Ongoing advances in performance rubber and green tires sustain high silica consumption.

Moreover, the regional architectural and industrial coatings industry widely uses silica for anti-settling, durability enhancement, and rheology control. High adoption of advanced coatings fuels steady demand for precipitated and fumed silica. North America’s nutraceutical and pharmaceutical industries depend on silica as an excipient, anti-caking agent, and glidant. Strict safety and quality standards augment the use of high-purity silica in supplements and medications.

Fumed Silica and Precipitated Silica Market: Competitive Analysis

The leading players in the global fumed silica and precipitated silica market are:

- Evonik Industries AG

- Cabot Corporation

- Wacker Chemie AG

- Solvay SA

- PPG Industries Inc.

- Tokuyama Corporation

- Oriental Silicas Corporation

- OCI Company Ltd.

- Quechen Silicon Chemical Co. Ltd.

- Zhuzhou Xinglong New Materials

- Wuxi Hengcheng Silicon Industry Co. Ltd.

- Sanming Fengrun Chemical Industry Co. Ltd.

- Shandong Link Science and Technology Co. Ltd.

- Fujian Yuanxiang New Materials Co. Ltd.

- Huber Engineered Materials

What are the key trends in the global Fumed Silica and Precipitated Silica Market?

Growing demand from the electric vehicle (EV) and green tire market:

Silica is steadily used in green tires to enhance fuel efficiency, wear resistance, and wet grip. The growth of electric vehicles and environmentally friendly mobility solutions is fueling this demand. Hence, manufacturers are investing in optimized silica formulations for high-performance tires.

Sustainability and eco‑friendly production practices:

Producers are adopting energy-efficient, cleaner manufacturing techniques that reduce emissions. There is also surging interest in recycled or bio-based silica variants to meet sustainability standards. End users increasingly prefer inert, non-toxic additives over conventional chemical substitutes.

The global fumed silica and precipitated silica market is segmented as follows:

By Product Form

- Powdered Precipitated Silica

- Granulated Precipitated Silica

By Application

- Paints and Coatings

- Polymers and Plastics

- Medications and Healthcare

By End-Use Industry

- Tire Manufacturing

- Rubber Goods

- Personal Care and Cosmetics

- Food and Feed Additives

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed