DIY Photoresist Market Size, Share, Global Trends, Forecast 2034

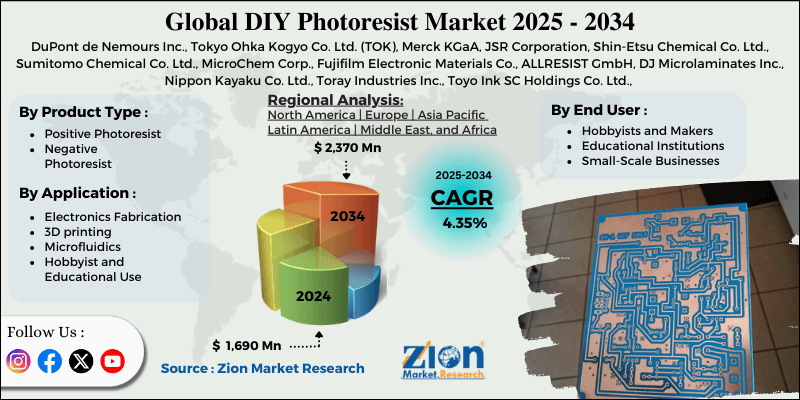

DIY Photoresist Market By Product Type (Positive Photoresist, Negative Photoresist), By Application (Electronics Fabrication, 3D Printing, Microfluidics, Hobbyist, and Educational Use), By End-User (Hobbyists and Makers, Educational Institutions, Small-Scale Businesses), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

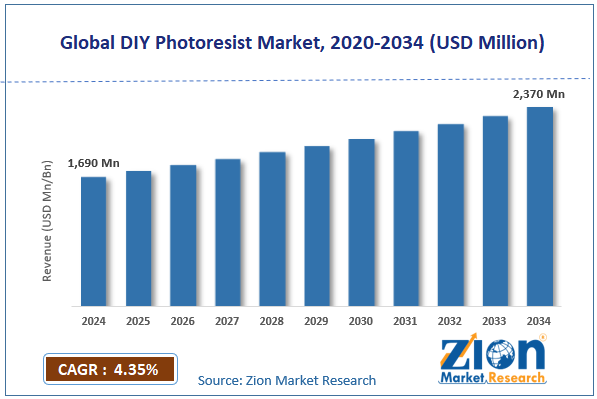

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 1,690 Million | USD 2,370 Million | 4.35% | 2024 |

DIY Photoresist Industry Perspective:

The global DIY photoresist market size was approximately USD 1,690 million in 2024 and is projected to reach around USD 2,370 million by 2034, with a compound annual growth rate (CAGR) of approximately 4.35% between 2025 and 2034.

DIY Photoresist Market: Overview

DIY photoresists are do-it-yourself applications or formulations of light-sensitive materials used in the photolithography procedure, usually for hobbyist-level or small-scale fabrication. They are largely used in printed circuit boards, custom micro-patterns, and microfluidic devices. DIY variants are typically made from pre-made sheets or readily available chemicals that can be processed using household equipment or UV light. The global DIY photoresist market is expected to expand rapidly, driven by the growing DIY culture and maker movement, surging demand for low-cost prototyping, and online community support and knowledge sharing. The global growth of maker communities, open-source hardware platforms, and FabLabs has nurtured and driven the demand for DIY photolithography technologies, such as photoresists. These communities prosper on experimentation and innovation, needing affordable materials for prototyping MEMS and microelectronics.

Additionally, research teams and startups require cost-effective prototyping techniques before scaling to industrial production. Do-it-yourself photoresists offer cost-effective lithography solutions compared to commercial photoresist systems used in semiconductor fabrication facilities (fabs). Additionally, websites, forums, open-source guides, and YouTube channels simplify the process of creating and utilizing DIY photoresists. This easy availability decreases barriers for entry-level users and propels the market demand.

Despite the growth, the global market is hindered by factors such as lower performance compared to industrial resins, inconsistent formulation, and a short shelf life. Do-it-yourself photoresists usually lack the thermal stability, resolution, and adhesion properties of commercial photoresists, restricting their use to low-resolution and non-critical applications. Several DIY resists degrade quickly or require specific environmental conditions, leading to low commercial scalability and inconsistent results.

Nonetheless, the global DIY photoresist industry stands to gain from several key opportunities, including pre-made DIY photoresist products, institutional and academic collaborations, and the growth of personalized electronics. There is a growing opportunity for niche suppliers and startups to create standardized DIY kits containing pre-measured, safe resists, developers, UV tools, and masks for makers and education. DIY photoresist vendors can also collaborate with research labs and universities to promote low-cost lithography as a solution for education and rapid research.

Furthermore, as trends such as smart tattoos, wearable health devices, and consumer IoT emerge, the demand for customizable and low-cost circuit patterning, which DIY photoresists can support, also increases.

Key Insights:

- As per the analysis shared by our research analyst, the global DIY photoresist market is estimated to grow annually at a CAGR of around 4.35% over the forecast period (2025-2034)

- In terms of revenue, the global DIY photoresist market size was valued at around USD 1,690 million in 2024 and is projected to reach USD 2,370 million by 2034.

- The DIY photoresist market is projected to grow significantly due to improved access to affordable equipment, STEM and educational initiatives, and advancements in photosensitive materials.

- Based on product type, the positive photoresist segment is expected to lead the market, while the negative photoresist segment is expected to grow considerably.

- Based on application, the hobbyist and educational use segment is the largest, while the electronics fabrication segment is projected to experience substantial revenue growth over the forecast period.

- Based on end-user, the hobbyists and makers segment is expected to lead the market compared to the educational institutions segment.

- Based on region, Asia Pacific is projected to dominate the global market during the estimated period, followed by North America.

DIY Photoresist Market: Growth Drivers

Surging demand for small-batch and custom electronics fuels market growth

Modern product design is highly favorable to low-volume manufacturing and customization. Design companies and startups developing wearables, IoT devices, or prototypes often require design flexibility and fast turnaround times, making industrial photolithography unfeasible. Do-it-yourself photoresist solutions allow sensor development and in-house PCB prototyping.

Additionally, low-cost photoresists enable design iteration at the desktop level. This trend is fueling the sales of mask aligners, UV exposure boxes, and photoresist emulsions specially designed for low-scale production, directly strengthening the growth of the DIY photoresist market.

Broader availability through open-source communities and e-commerce notably propels the market growth

The accessibility of DIY photoresist materials has increased dramatically through online platforms such as AliExpress, Amazon, Mouser, and Digi-Key. This enables global distribution and exposure to previously underserved regions in Latin America, South Asia, and Africa.

The open-source hardware movement has also aided the proliferation of photoresist use. Popular DIY electronics platforms, such as Raspberry Pi and Arduino, typically feature companion tutorials that include customized PCBs with photoresist. As of May 2024, GitHub hosts over 18,000 repositories related to PCB etching and DIY photolithography.

DIY Photoresist Market: Restraints

Growing competition from alternative digital fabrication technologies adversely impacts market progress

The increasing availability of alternative desktop fabrication techniques, such as 3D printing, CNC milling, and laser engraving with conductive inks, poses a competitive threat to the global DIY photoresist market. These solutions offer faster, cleaner, and increasingly cost-efficient options for small-sized circuit fabrication without needing chemical processes. This inclination towards digital and dry alternatives, a majority of which are less prone to and safer than chemical photoresist solutions, decreases the perceived need for chemical photoresist solutions, particularly in regions where cleanliness and ease of use are prioritized.

DIY Photoresist Market: Opportunities

Increasing demand in biomedical prototyping and wearables positively impacts market growth

The global progress in biomedical device and wearable technology research and development is creating the demand for low-cost microfabrication solutions. This is mainly for electrodes, prototyping sensors, and circuit patterns on biocompatible or flexible substrates. Do-it-yourself formulations can serve these requirements by allowing rapid and in-lab patterning of electrodes on materials such as PDMS, PET, or hydrogels.

Researchers at the Tokyo University of Science created a stretchable biosensor using a modified DIY photoresist procedure on flexible substrates, which significantly reduces prototyping costs. Likewise, at MIT, do-it-yourself lithography was used to generate sweat-monitoring patches for athletes. This offered new use applications for lab-based and homegrown photolithography systems, impacting the global DIY photoresist industry.

DIY Photoresist Market: Challenges

Varying product quality across global supply chains restricts the growth of market

Unregulated production and global sourcing contribute to significant inconsistencies in the quality of DIY photoresist products, primarily from low-cost suppliers. Differences in formulations, UV sensitivity, and developer composition are often misrepresented or undocumented in product listings, leading to user confusion. Additionally, geopolitical trade issues and varying import policies have created supply chain barriers.

DIY Photoresist Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | DIY Photoresist Market |

| Market Size in 2024 | USD 1,690 Million |

| Market Forecast in 2034 | USD 2,370 Million |

| Growth Rate | CAGR of 4.35% |

| Number of Pages | 216 |

| Key Companies Covered | DuPont de Nemours Inc., Tokyo Ohka Kogyo Co. Ltd. (TOK), Merck KGaA, JSR Corporation, Shin-Etsu Chemical Co. Ltd., Sumitomo Chemical Co. Ltd., MicroChem Corp., Fujifilm Electronic Materials Co., ALLRESIST GmbH, DJ Microlaminates Inc., Nippon Kayaku Co. Ltd., Toray Industries Inc., Toyo Ink SC Holdings Co. Ltd., Kolon Industries Inc., Mitsubishi Chemical Group Corporation, and others. |

| Segments Covered | By Product Type, By Application, By End User, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

DIY Photoresist Market: Segmentation

The global DIY photoresist market is segmented based on product type, application, end user, and region.

Based on product type, the global DIY photoresist industry is divided into positive photoresist and negative photoresist. The positive photoresist segment holds a substantial market share due to its ease of use, more straightforward processing steps, and improved resolution, which hobbyists, beginners, and academic users highly prefer. When exposed to UV light, these areas become prone to solubility, aiding direct development with basic chemicals. This makes them especially ideal for creating fine patterns in microfluidic devices and PCBs. Additionally, several commercially available DIY photoresist films rely on positive resists, thereby enhancing their industry dominance.

Based on application, the global DIY photoresist market is segmented into electronics fabrication, 3D printing, microfluidics, and hobbyist and educational use. The hobbyist and educational use segment holds a larger share of the market, fueled by broader adoption in maker spaces, universities, DIY electronics communities, and schools. The low cost, simplicity, and increasing availability of instructional content make photoresist an appealing option for hands-on learning, student projects, and basic microfabrication. The global focus on STEM education, along with institutional and government support, has driven the adoption of DIY photoresists in this segment.

Based on end user, the global market is segmented into hobbyists and makers, educational institutions, and small-scale businesses. The hobbyists and makers segment accounted for a larger share of the industry, driven by the growth of the global maker movement and the increasing availability of low-cost fabrication tools. This group actively focused on PCB design, DIY electronics, microfluidics, and creative prototyping with photoresist materials for experimental or personal projects. The availability of open-source hardware, community forums, and online tutorials has made it easy for individuals to use photoresist technology without formal training.

DIY Photoresist Market: Regional Analysis

Asia Pacific to witness significant growth over the forecast period

The Asia Pacific is anticipated to retain its leading role in the global DIY photoresist market, driven by strong electronics and semiconductor infrastructure, booming DIY and maker communities, and government support for local manufacturing and innovation. The Asia Pacific region accounts for over 60% of global electronics manufacturing, led by nations such as South Korea, Japan, Taiwan, and China. This infrastructure propels the demand for low-cost prototyping and small-scale research and development, where do-it-yourself photoresists are broadly used for experiments. Researchers and hobbyists benefit from an abundant supply chain and access to locally manufactured photolithography parts.

The region has experienced rapid growth in DIY culture and maker spaces, primarily in India, Japan, and China, where digital fabrication tools are gaining widespread acceptance. This culture has made the APAC region a leading consumer of DIY fabrication components and kits. Initiatives such as the 'Digital New Deal' by South Korea, 'Made in China 2025' by China, and 'Make in India' by India promote technology entrepreneurship and localized innovation. These programs typically include funding for makerspaces, microelectronics labs, and research infrastructure utilizing DIY methods. Such policy backing creates favorable conditions for the advancement of DIY photoresist use.

North America ranks as the second-largest region in the global DIY photoresist industry, driven by the strong presence of DIY and Maker communities, robust academic research and STEM education, and well-developed distribution channels and e-commerce platforms. North America, particularly the United States, is home to some of the leading and earliest DIY and maker ecosystems. Platforms like Maker Faire, Adafruit, and Hackaday have millions of followers and users engaged in photolithography and small-scale electronics projects.

The United States alone invests more than USD 700 billion yearly in education, with key emphasis on hands-on learning and STEM. Universities such as Georgia Tech, Stanford, and MIT integrate lithography and microfabrication into their engineering curricula, often using DIY photoresist kits for instructional purposes. Thousands of community colleges and high schools also run lab-based STEM programs, thus increasing market reach.

Moreover, platforms like SparkFun, Amazon, and Adafruit sell DIY photoresist materials, kits, and UV exposure directly to institutions and individuals. This robust e-commerce infrastructure enables broader accessibility and supports a distributed consumer base in Canada and the U.S. North America is a leader in online sales of niche electronics and do-it-yourself materials globally.

DIY Photoresist Market: Competitive Analysis

The leading players profiled in the global DIY photoresist market are:

- DuPont de Nemours Inc.

- Tokyo Ohka Kogyo Co. Ltd. (TOK)

- Merck KGaA

- JSR Corporation

- Shin-Etsu Chemical Co. Ltd.

- Sumitomo Chemical Co. Ltd.

- MicroChem Corp.

- Fujifilm Electronic Materials Co.

- ALLRESIST GmbH

- DJ Microlaminates Inc.

- Nippon Kayaku Co. Ltd.

- Toray Industries Inc.

- Toyo Ink SC Holdings Co. Ltd.

- Kolon Industries Inc.

- Mitsubishi Chemical Group Corporation

DIY Photoresist Market: Key Market Trends

Integration with Hybrid Fabrication and 3D Printing:

DIY photoresists are widely used in conjunction with 3D printing for hybrid microfabrication workflows. Researchers are assimilating additive manufacturing and UV lithography to create complex microfluidic devices, MEMS structures, or electronics. This cross-synergy enables speedy prototyping of numerous devices within budget.

Move towards low-toxicity and eco-friendly formulations:

With the rising ecological awareness, DIY users are preferring non-toxic, safer, and biodegradable photoresist materials. Researchers are developing PVA-based and water-based alternatives to traditional solvents, such as xylene and acetone. This green chemistry trend is mainly essential in home labs, schools, and eco-conscious maker spaces.

The global DIY photoresist market is segmented as follows:

By Product Type

- Positive Photoresist

- Negative Photoresist

By Application

- Electronics Fabrication

- 3D printing

- Microfluidics

- Hobbyist and Educational Use

By End User

- Hobbyists and Makers

- Educational Institutions

- Small-Scale Businesses

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

DIY photoresists are do-it-yourself applications or formulations of light-sensitive materials used in the photolithography procedure, usually for hobbyist-level or small-scale fabrication. They are largely used in printed circuit boards, custom micro-patterns, and microfluidic devices. DIY variants are typically made from pre-made sheets or readily available chemicals that can be processed using household equipment or UV light.

The global DIY photoresist market is projected to grow due to innovations, the rise in home-based prototyping, the growing trend of open-source hardware development, and the increasing demand for digital knowledge sharing and content creation.

According to study, the global DIY photoresist market size was worth around USD 1,690 million in 2024 and is predicted to grow to around USD 2,370 million by 2034.

The CAGR value of the DIY photoresist market is expected to be approximately 4.35% from 2025 to 2034.

Asia Pacific is expected to lead the global DIY photoresist market during the forecast period.

The key players profiled in the global DIY photoresist market include DuPont de Nemours, Inc., Tokyo Ohka Kogyo Co., Ltd. (TOK), Merck KGaA, JSR Corporation, Shin-Etsu Chemical Co., Ltd., Sumitomo Chemical Co., Ltd., MicroChem Corp., Fujifilm Electronic Materials Co., ALLRESIST GmbH, DJ Microlaminates, Inc., Nippon Kayaku Co., Ltd., Toray Industries, Inc., Toyo Ink SC Holdings Co., Ltd., Kolon Industries, Inc., and Mitsubishi Chemical Group Corporation.

The report examines key aspects of the DIY photoresist market, including a detailed analysis of existing growth factors and restraints, as well as an examination of future growth opportunities and challenges that will impact the market.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed