Cold Forging Machines Market Size, Share, Growth & Forecast 2034

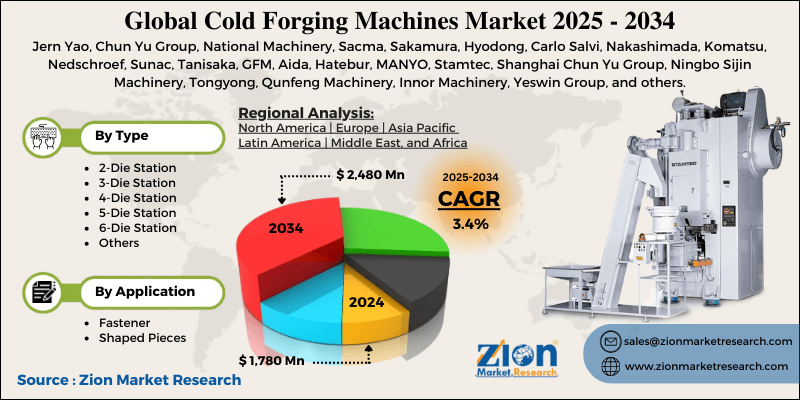

Cold Forging Machines Market By Type (2-Die Station, 3-Die Station, 4-Die Station, 5-Die Station, 6-Die Station, and Others), By Application (Fastener and Shaped Pieces), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

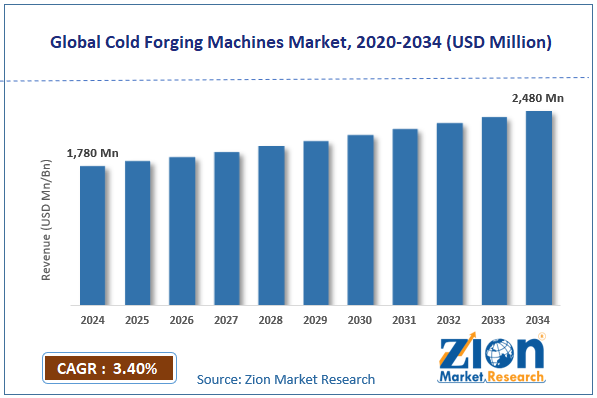

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 1,780 Million | USD 2,480 Million | 3.4% | 2024 |

Cold Forging Machines Industry Perspective:

The global cold forging machines market size was worth around USD 1,780 million in 2024 and is predicted to grow to around USD 2,480 million by 2034 with a compound annual growth rate (CAGR) of roughly 3.4% between 2025 and 2034.

Key Insights

- As per the analysis shared by our research analyst, the global cold forging machines market is estimated to grow annually at a CAGR of around 3.4% over the forecast period (2025-2034).

- In terms of revenue, the global cold forging machines market size was valued at around USD 1,780 million in 2024 and is projected to reach USD 2,480 million by 2034.

- The increasing demand from the end-use sector, such as automotive, is expected to drive the cold forging machines market over the forecast period.

- Based on the type, the 4-die station segment is expected to capture the largest market share over the projected period.

- Based on the application, the fastener segment holds the major market share.

- Based on region, the Asia Pacific is expected to dominate the market during the forecast period.

Cold Forging Machines Market: Overview

Cold forging, also called cold forming or cold heading, is a process to shape metal without utilizing heat at room temperature or slightly higher. Cold forging is not the same as hot forging because it doesn't heat the metal above its recrystallization temperature. This maintains the material's grain structure intact, which makes it stronger. Choosing the correct material, getting it ready, shaping it, and finishing it are the usual processes in the cold forging process. Cold forging is now a flexible and useful approach to creating machine parts of high quality. With a cold forge, one shapes metal at room temperature. It offers numerous benefits, including strengthening the metal, reducing costs, enhancing surface polish, improving dimensional accuracy, and minimizing resource consumption.

Because of these benefits, numerous industries, such as automotive, aerospace, electronics, and consumer products, employ cold forged parts extensively. The market growth is majorly driven by several factors, such as the growing need for lightweight, high-strength components, the growth of automotive, aerospace & EVs, and the increasing demand for cost reduction/efficiency. However, the high initial capital/setup cost might pose a major challenge to the industry's growth.

Cold Forging Machines Market Dynamics

Growth Drivers

Do the favorable properties of these machines drive the cold forging machines market growth?

The favorable aspects of cold forging machines are anticipated to fuel the cold forging machines market. Some of the positive aspects about it are that it has better mechanical properties, higher dimensional precision and surface polish, it saves materials, it can manufacture complicated parts, it has quick production cycles, and more. Cold forging modifies the metal's grain structure, which makes products that are stronger, tougher, more resistant to wear and fatigue, and better for high-stress purposes. Cold forging may also build complicated structures with fine internal details and threads due to the tremendous forces applied. Cold forging machines are used to create high-strength automotive parts, such as bolts, gears, shafts, and aerospace components, which must be manufactured to extremely precise technical specifications.

Restraints

How does the lack of a skilled workforce hinder the cold forging machines market growth?

It's incredibly hard to manage and keep up with advanced cold forging technologies because there aren't enough competent personnel. This can slow down production, manufacture products of low quality, stress personnel, and make it tougher to start new projects. A 2023 survey found that several manufacturers reported that not having enough trained personnel hindered their earnings. Researchers are looking into emerging technologies like AI and robotics, as well as automation, as viable solutions to this challenge. Therefore, the lack of skilled personnel is a significant obstacle to the industry's expansion.

Opportunities

How do scientific advancement and continuous innovation offer a potential opportunity for the cold forging machines industry’s growth?

In today's competitive market, it's important to make high-quality products at prices that are competitive. This leads to fewer, more efficient metal forming processes, the elimination of secondary operations, and the maintenance of surface polish, tolerance, and dimensional standards. It is important to find a process that meets the design requirements and is also affordable for the amount of production needed. One way to reach this goal is to make a model of the process for making net shapes.

The Engineering Research Center is conducting research on cold and warm forging, which is beneficial to the industry, as this study demonstrates, aiming to enhance quality and reduce costs. It talks about modern research on the design of fuel injector nozzle sequences, fracture modeling during induction heating, and modeling. The International Forging Industry Association reports that more than 62% of firms are using automated cold forging systems to cut down on manual work and improve accuracy by up to 25%, especially when making parts for cars.

Challenges

Competition from alternative technology to pose a major challenge to market expansion

Cold forging machines generally compete with other ways to form metal, such as hot forging, warm forging, machining, casting, and extrusion. Each process has its own pros and cons, which depend on the application, the material, the number of parts being made, and how complicated the parts are. There are always new ways to approach processes such as casting, hot forging, warm forging, precision machining, stamping, and additive manufacturing.

In other situations, they might be cheaper, more flexible, or better suited for handling shapes that are hard to work with. If companies that create cold forging equipment want to stay competitive, they need to continuously come up with fresh innovations. This is why the cold forging machine market is having difficulties, as competing technologies are getting more popular.

Cold Forging Machines Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Cold Forging Machines Market |

| Market Size in 2024 | USD 1,780 Million |

| Market Forecast in 2034 | USD 2,480 Million |

| Growth Rate | CAGR of 3.4% |

| Number of Pages | 216 |

| Key Companies Covered | Jern Yao, Chun Yu Group, National Machinery, Sacma, Sakamura, Hyodong, Carlo Salvi, Nakashimada, Komatsu, Nedschroef, Sunac, Tanisaka, GFM, Aida, Hatebur, MANYO, Stamtec, Shanghai Chun Yu Group, Ningbo Sijin Machinery, Tongyong, Qunfeng Machinery, Innor Machinery, Yeswin Group, and others. |

| Segments Covered | By Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Cold Forging Machines Market: Segmentation

The global cold forging machines industry is segmented based on type, application, and region.

Based on the type, the global cold forging machines market is bifurcated into 2-die station, 3-die station, 4-die station, 5-die station, 6-die station, and others. The 4-die station segment is expected to capture the largest market share over the projected period. The growth of the segment is attributed to the enhanced reproducibility and precision. 4-die stations increase grain orientation characteristics, resulting in higher surface smoothness, strength, and dimensional tolerances required for performance-critical components.

Furthermore, cold forging machines, particularly 4-die models, save up to 30% more material than conventional machining, lowering production costs in critical industries. Thus, driving the segment expansion.

Based on the application, the global cold forging machines industry is bifurcated into fastener and shaped pieces. The fastener segment holds the major market share. The fastener industry is a primary driver of demand for cold forging equipment, particularly in the automotive manufacturing sector, where high-strength, lightweight fasteners such as bolts, screws, and nuts are crucial for assembly and safety. Furthermore, the automobile industry's push for lightweight vehicles, electric and hybrid models, and higher safety regulations necessitates the use of specialist fasteners made through cold forging to ensure superior strength and corrosion resistance.

Cold Forging Machines Market: Regional Analysis

Why does the Asia Pacific dominate the cold forging machines market over the projected period?

The Asia Pacific is expected to dominate the global cold forging machines market over the projected period. The market is rising in the Asia Pacific area for two main reasons: the rapid growth of the industry and a strong manufacturing base. China, Japan, India, South Korea, and countries in Southeast Asia are important areas for making products like planes, cars, and industrial equipment. As infrastructure and industry keep growing, there is also a growing need for cold forging machines, which manufacture robust, long-lasting parts.

The India Brand Equity Foundation states that in March 2025, a total of 24,76,915 passenger vehicles, three-wheelers, two-wheelers, and quadricycles were manufactured. India's car exports went up by 19% in FY25, reaching over 5.3 million units. This happened because more people in other countries wanted passenger automobiles, two-wheelers, and commercial vehicles.

Cold Forging Machines Market: Competitive Analysis

The global cold forging machines market is dominated by players like:

- Jern Yao

- Chun Yu Group

- National Machinery

- Sacma

- Sakamura

- Hyodong

- Carlo Salvi

- Nakashimada

- Komatsu

- Nedschroef

- Sunac

- Tanisaka

- GFM

- Aida

- Hatebur

- MANYO

- Stamtec

- Shanghai Chun Yu Group

- Ningbo Sijin Machinery

- Tongyong

- Qunfeng Machinery

- Innor Machinery

- Yeswin Group

The global cold forging machines market is segmented as follows:

By Type

- 2-Die Station

- 3-Die Station

- 4-Die Station

- 5-Die Station

- 6-Die Station

- Others

By Application

- Fastener

- Shaped Pieces

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Cold forging, which is also called cold forming or cold heading, is a process to shape metal without utilizing heat at room temperature or slightly higher. Cold forging is not the same as hot forging because it doesn't heat the metal above its recrystallization temperature.

The cold forging machines market growth is majorly driven by several factors such as growing need for lightweight, high-strength components, growth of automotive, aerospace & EVs, and increasing demand for cost reduction/efficiency.

The high initial capital/setup cost might pose a major challenge to the cold forging machines industry's growth.

Based on the application, the fastener segment is expected to dominate the industry growth during the projected period.

The increasing automotive sector and technological advancements pose a major impact factor for the cold forging machines industry's growth over the projected period.

According to the report, the global cold forging machines market size was worth around USD 1,780 million in 2024 and is predicted to grow to around USD 2,480 million by 2034.

The global cold forging machines market is expected to grow at a CAGR of 3.4% during the forecast period.

The global cold forging machines industry growth is expected to be driven by the Asia Pacific region. It is currently the world’s highest-revenue-generating market, driven by the presence of major players and increasing demand from the end-use sector.

The global cold forging machines market is dominated by players like Jern Yao, Chun Yu Group, National Machinery, Sacma, Sakamura, Hyodong, Carlo Salvi, Nakashimada, Komatsu, Nedschroef, Sunac, Tanisaka, GFM, Aida, Hatebur, MANYO, Stamtec, Shanghai Chun Yu Group, Ningbo Sijin Machinery, Tongyong, Qunfeng Machinery, Innor Machinery, and Yeswin Group, among others.

The cold forging machines market report covers the geographical market along with a comprehensive competitive landscape analysis. It also includes cash flow analysis, profit ratio analysis, market basket analysis, market attractiveness analysis, sentiment analysis, PESTLE analysis, trend analysis, SWOT analysis, trade area analysis, demand & supply analysis, Porter’s five forces analysis, and value chain analysis.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed