Automotive Diff Pinion Gear Market Size, Share, Trends, Growth 2034

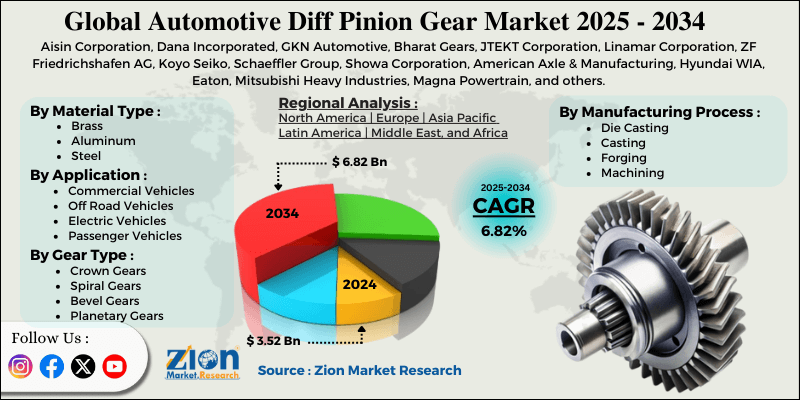

Automotive Diff Pinion Gear Market By Material Type (Brass, Aluminum, Steel, Iron, and Others), By Application (Commercial Vehicles, Off Road Vehicles, Electric Vehicles, and Passenger Vehicles), By Gear Type (Crown Gears, Spiral Gears, Bevel Gears, and Planetary Gears), By Manufacturing Process (Die Casting, Casting, Forging, and Machining), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

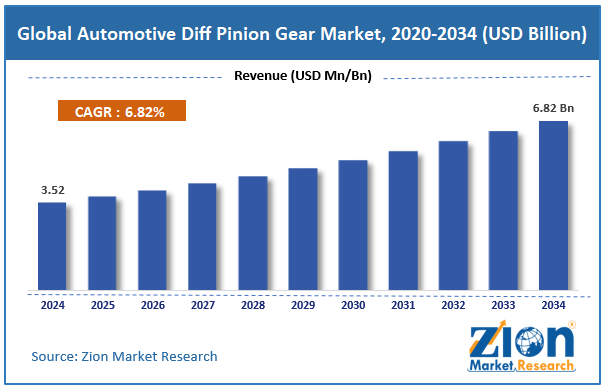

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 3.52 Billion | USD 6.82 Billion | 6.82% | 2024 |

Automotive Diff Pinion Gear Industry Perspective:

What will be the size of the global automotive diff pinion gear market during the forecast period?

The global automotive diff pinion gear market size was worth around USD 3.52 billion in 2024 and is predicted to grow to around USD 6.82 billion by 2034 with a compound annual growth rate (CAGR) of roughly 6.82% between 2025 and 2034.

Key Insights:

- As per the analysis shared by our research analyst, the global automotive diff pinion gear market is estimated to grow annually at a CAGR of around 6.82% over the forecast period (2025-2034)

- In terms of revenue, the global automotive diff pinion gear market size was valued at around USD 3.52 billion in 2024 and is projected to reach USD 6.82 billion by 2034.

- The automotive diff pinion gear market is projected to grow at a significant rate due to the rising demand for performance vehicles.

- Based on the material type, the steel segment is growing at a high rate and will continue to dominate the global market, as per industry projections

- Based on the gear type, the bevel gears segment is anticipated to command the largest market share

- Based on region, the Asia-Pacific is projected to dominate the global market during the forecast period

Automotive Diff Pinion Gear Market: Overview

An automotive differential pinion gear is a precision component of the vehicle that ensures stability and smooth power transfer. The diff pinion gear is essential for effective and accurate torque distribution between automotive wheels, especially during turns. According to industry analysis, diff pinion gears are a part of the larger differential assembly of a vehicle and help in wheel rotation at different speeds. The demand for automotive differential pinion gears is projected to grow significantly during the forecast period, driven by rising end-user applications.

For instance, these gears are extensively used in commercial and passenger vehicles. Additionally, differential pinion gears are among some of the most crucial elements of the performance of off-road vehicles. During the forecast period, innovations in diff pinion gear technologies and solutions will help enhance market revenue. However, the industry is expected to be restricted due to fluctuations reported in the raw material supply chain and the high cost of pinion gear production.

Automotive Diff Pinion Gear Market: Dynamics

Growth Drivers

How will increased demand for performance vehicles influence the automotive diff pinion gear market growth?

The global automotive diff pinion gear market is expected to be led by the rising demand for performance vehicles. The specialized diff ring gears are designed to handle high torque without impacting vehicle stability. In addition, they deliver exceptional traction control. Automotive diff pinion gears have also found applications in off-road vehicles due to their ability to deliver an enhanced driving experience while ensuring passenger safety. The rising production of performance and off-road vehicles will subsequently work in favor of the pinion gear solution providers.

For instance, in September 2025, Porsche, one of the world’s leading luxury performance vehicle brands, announced the launch of the new 2026 911 Turbo S. According to official reports, the new range is the brand's most powerful production 911 to date, powered by a twin-turbo powertrain with T-Hybrid technology. Similar innovations in performance and off-road vehicles can be reported across luxury and affordable brands as consumer preferences continue to evolve.

Growing demand for ride-hailing and ride-sharing solutions to help fuel market expansion

In the last few years, the automotive industry has witnessed an increasing demand for ride-hailing and ride-sharing solutions. These concepts offer cost-effectiveness and are also considered environmentally friendly. In addition, the growing use of modern digital technologies, such as applications and software, has further eased the process of connecting with ride-sharing or ride-hailing service providers. Companies operating in these sectors rely heavily on fuel-efficient automotives that also offer superior passenger safety. The rapid expansion of ride-sharing services will promote increased demand for effective automotive diff pinion gears in the coming years.

For instance, in December 2025, Uber Technologies, Inc. announced that passengers can now match Dallas riders with robotaxis by Avride. The move has not unlocked a new way to access Uber services. Such innovative strategies are likely to work in favor of the global automotive diff pinion gear market during the projection period.

Restraints

What will be the impact of fluctuating raw material prices on the automotive diff pinion gear market?

The global automotive diff pinion gear industry is expected to be restricted due to the rising impact of fluctuating raw material supply chain and prices. Different pinion gears are generally made of materials such as steel, brass, iron, or aluminum. The prices of these elements are subject to frequent changes depending on several external factors, such as geopolitical partnerships and import-export restrictions. These changes can impact business market decisions in the long run and limit market expansion during the projection period.

Opportunities

Expansion of the electric vehicle (EV) sector offers expansion possibilities to the industry players

The global automotive diff pinion gear market is expected to generate growth opportunities due to the rising expansion of the EV sector. In addition, the surging popularity of hybrid vehicles may further demand innovation in the production of automotive differential pinion gears. These vehicles rely heavily on lightweight but high-performance components, encouraging market players to invest more in research & development. In April 2025, Eaton, a leading intelligent power management company, announced the launch of its latest offering in the form of EV Truetrac.

The differential is specifically designed for EVs and addresses challenges observed in electric vehicle propulsion systems, such as increased sensitivity to noise, shared low-viscosity oil environments, and the demands of high, instantaneous torque delivery. In July 2025, BorgWarner announced that it had secured a new deal for the company’s electric cross differential (eXD) technology with a leading China-based original equipment manufacturer (OEM). The differential offered by BorgWarner will be used in electric vehicles across China.

Challenges

Which challenges will the high cost of manufacturing create for the automotive diff pinion gear market?

The global industry for automotive diff pinion gears is anticipated to be challenged by the high cost of producing the components. Manufacturing of differential pinion gear requires high precision solutions along with advanced heat-treatment & machining processes. The final cost of production is heavily influenced by skilled labor requirements and the use of expensive tools.

Automotive Diff Pinion Gear Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Automotive Diff Pinion Gear Market |

| Market Size in 2024 | USD 3.52 Billion |

| Market Forecast in 2034 | USD 6.82 Billion |

| Growth Rate | CAGR of 6.82% |

| Number of Pages | 215 |

| Key Companies Covered | Aisin Corporation, Dana Incorporated, GKN Automotive, Bharat Gears, JTEKT Corporation, Linamar Corporation, ZF Friedrichshafen AG, Koyo Seiko, Schaeffler Group, Showa Corporation, American Axle & Manufacturing, Hyundai WIA, Eaton, Mitsubishi Heavy Industries, Magna Powertrain, and others. |

| Segments Covered | By Material Type, By Application, By Gear Type, By Manufacturing Process, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Automotive Diff Pinion Gear Market: Segmentation

The global automotive diff pinion gear market is segmented based on material type, application, gear type, manufacturing process, and region.

Based on material type, the global market is segmented into brass, aluminum, steel, iron, and others. In 2024, the highest growth was listed in the steel segment. The material offers excellent performance in terms of strength and durability. Additionally, steel-based automotive differential pinion gears are more cost-effective than other alternatives. The rising use of steel components in modern vehicles will promote segmental expansion in the future.

Based on application, the global automotive diff pinion gear industry is divided into commercial vehicles, off-road vehicles, electric vehicles, and passenger vehicles.

Based on gear type, the global market is divided into crown gears, spiral gears, bevel gears, and planetary gears. The highest revenue was observed in the bevel gears segment in 2024, and similar trends are expected to emerge in the future. It is the most primary type of gears used in new-age automotives. Additionally, bevel gears can handle extreme load and torque, further helping the segment thrive in the coming years.

Based on the manufacturing process, the global industry is divided into die casting, casting, forging, and machining.

Automotive Diff Pinion Gear Market: Regional Analysis

Why will Asia-Pacific emerge as the market leader in the automotive diff pinion gear market?

The global automotive diff pinion gear market will be led by Asia-Pacific during the forecast period. It is expected to deliver a CAGR of more than 6.9% in the coming years. Growth in Asia-Pacific is a result of the higher dominance of countries such as China, India, South Korea, and Japan in the automotive space. Asian countries are some of the largest producers and exporters of modern and conventional automotive components. The presence of a robust and growing manufacturing industry, along with greater investments in the EV sector, will help the region excel during the projection period.

North America is anticipated to emerge as the second-highest revenue generator with a CAGR of around 5.4%. North America has a mature automotive industry, which helps promote demand for differential pinion gears. Additionally, the rising demand for performance vehicles and off-road vehicles further fuels the accelerated demand for differential pinion gears.

North American growth rate is expected to be promoted by the surging investments in fleet-led demand for commercial vehicles, along with the growing use of automotives in ride-sharing services. In addition, the rapid expansion of the regional automobile industry across the global landscape will further promote higher revenue in North America.

Automotive Diff Pinion Gear Market: Competitive Analysis

The global automotive diff pinion gear market is led by players like:

- Aisin Corporation

- Dana Incorporated

- GKN Automotive

- Bharat Gears

- JTEKT Corporation

- Linamar Corporation

- ZF Friedrichshafen AG

- Koyo Seiko

- Schaeffler Group

- Showa Corporation

- American Axle & Manufacturing

- Hyundai WIA

- Eaton

- Mitsubishi Heavy Industries

- Magna Powertrain

What are the key trends in the global Automotive Diff Pinion Gear Market?

Introduction of next-generation gears

A promising trend in the automotive diff pinion gear industry is the introduction of next-generation solutions capable of handling high torque and driving demands. Recent technological innovations reported in the market are torque vectoring, electronic limited-slip differentials, and smart control systems.

Eco-friendly practices

Industry players are working on integrating eco-friendly differential pinion gear manufacturing processes. This trend is strongly influenced by stringent regulatory standards and the growing demand for fuel- or power-efficient vehicles among end users.

The global automotive diff pinion gear market is segmented as follows:

By Material Type

- Brass

- Aluminum

- Steel

- Iron

- Others

By Application

- Commercial Vehicles

- Off Road Vehicles

- Electric Vehicles

- Passenger Vehicles

By Gear Type

- Crown Gears

- Spiral Gears

- Bevel Gears

- Planetary Gears

By Manufacturing Process

- Die Casting

- Casting

- Forging

- Machining

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed