3D Laser Cutting Robot Market Size, Share, Trends, Growth 2034

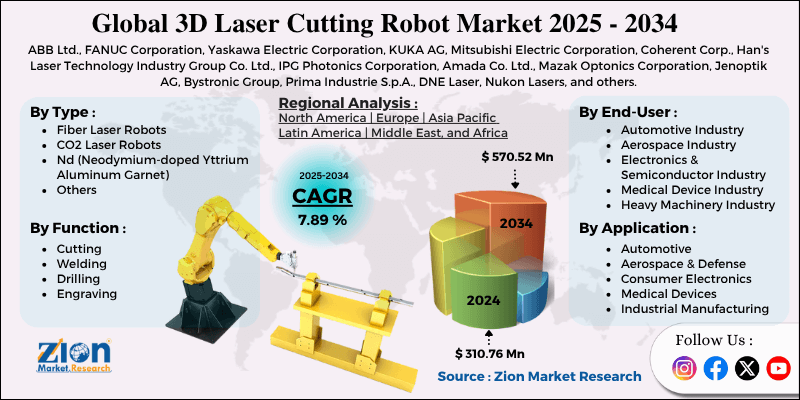

3D Laser Cutting Robot Market By Type (Fiber Laser Robots, CO2 Laser Robots, Nd [Neodymium-doped Yttrium Aluminum Garnet], and Others), By Function (Cutting, Welding, Drilling, Engraving, and Others), By Application (Automotive, Aerospace & Defense, Consumer Electronics, Medical Devices, Industrial Manufacturing, and Others), By End-User Industry (Automotive Industry, Aerospace Industry, Electronics and Semiconductor Industry, Medical Device Industry, Heavy Machinery Industry, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

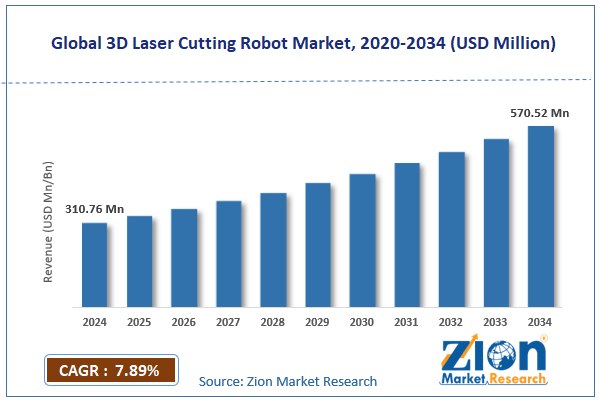

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 310.76 Million | USD 570.52 Million | 7.89% | 2024 |

3D Laser Cutting Robot Industry Perspective:

The global 3D laser cutting robot market size was approximately USD 310.76 million in 2024 and is projected to reach around USD 570.52 million by 2034, with a compound annual growth rate (CAGR) of approximately 7.89% between 2025 and 2034.

3D Laser Cutting Robot Market: Overview

A 3D laser cutting robot is a dedicated industrial system that integrates robotic arms with high-accuracy laser cutting technology to process complex 3D components. These robots are extensively used in industries such as metal fabrication, automotive, and aerospace for various purposes due to their high accuracy, speed, and flexibility. The global 3D laser cutting robot market is poised for notable growth due to the growing demand for automation in manufacturing, the rise of Industry 4.0, and the need for flexible manufacturing and customization. Global industries are actively automating to decrease human error, time-to-market, and labor costs. 3D laser cutting robots offer automated, seamless, and high-speed processing. Their ability to deliver consistent results increases their suitability for lean manufacturing. Smart factories depend on real-time data, interconnected systems, and robotics.

3D laser cutting robots are the ideal fit for Industry 4.0 architecture due to their automation and connectivity capabilities. They remarkably reduce human interference and enhance overall productivity. Improved production needs flexible manufacturing setups and quick retooling. 3D laser robots adapt quickly to design changes without the need for physical molds and dies. This allows producers to meet dynamic end-user demands with minimal downtime.

Nevertheless, the global market faces limitations due to factors such as complexity, integration, and a lack of a skilled workforce for maintenance and performance. Integrating robotic systems into legacy systems could be technically challenging. It needs custom interfaces, layout redesigns, and programming. This increases project cost and time, delaying return on investment for manufacturers. While robots minimize the need for human operators, skilled labors are still required for troubleshooting and setup.

Several regions lack a workforce capable of optimizing and maintaining these systems. This skill gap creates obstacles to effective operation. Still, the global 3D laser cutting robot industry benefits from several favorable factors, including the rise in sheet metal fabrication and adoption in medical device manufacturing. Sheet metal is extensively used in the furniture, appliance, and electronics industries.

3D laser robots offer burr-free, fast, and clean cuts, suitable for mass fabrication. The growing demand for precision components in these industries increases robust business demand. Medical implants and tools need high-precision and sterile-grade parts. 3D laser cutting robots are ideal for working with biocompatible metals, such as titanium. With the growing healthcare industry, the need for robotic precision in the fabrication of medical components also increases.

Key Insights:

- As per the analysis shared by our research analyst, the global 3D laser cutting robot market is estimated to grow annually at a CAGR of around 7.89% over the forecast period (2025-2034)

- In terms of revenue, the global 3D laser cutting robot market size was valued at around USD 310.76 million in 2024 and is projected to reach USD 570.52 million by 2034.

- The 3D laser cutting robot market is projected to grow significantly due to the growing adoption of Industry 4.0 practices and automation, reduction in material wastage and operational costs, and increasing labor costs, as well as a lack of skilled workforce.

- Based on type, the fiber laser robots segment is expected to lead the market, while the CO2 laser robots segment is expected to grow considerably.

- Based on function, the cutting is the dominant segment, while the welding segment is projected to witness sizable revenue growth over the forecast period.

- Based on application, the automotive segment holds a leading share, while the aerospace & defense segment gains a second leading share.

- Based on end-user industry, the automotive industry segment is expected to lead the market, followed by the aerospace industry segment.

- Based on region, the Asia Pacific is projected to dominate the global market during the estimated period, followed by Europe.

3D Laser Cutting Robot Market: Growth Drivers

How is the global 3D Laser Cutting Robot Market driven by the growth of aerospace and defense manufacturing?

Aerospace manufacturers rely on 3D laser cutting robots for the precision cutting of aluminum, titanium, and composite components used in turbine blades, fuselages, and missile components. The demand for repeatability, precision, and minimal heat-affected zones increases the suitability of laser cutting, which is vital in this domain.

In 2024, Boeing partnered with KUKA Robotics to install a new fleet of 3D laser cutting robots at its Seattle facility, enabling the production of next-generation aircraft. This technology will help the aircraft company reduce the production cycle by 15%, thus fueling the global 3D laser cutting robot market.

The growth of the electric vehicle sector remarkably fuels the market growth

The global trend towards electrification of mobility is driving the need for advanced manufacturing solutions. Electric vehicle components, such as structural supports, high-voltage housings, and battery trays, require lightweight, customized, and durable materials that are suitable for use in these robots' specific applications.

BYD invested more than $180 million in a novel production line featuring fully automated 3D laser cutting robots in Shenzhen in May 2024, to meet its expanding demand for electric vehicle body components. The investment is anticipated to increase output by 30% while reducing material waste.

3D Laser Cutting Robot Market: Restraints

How does limited flexibility in low-volume, custom production hamper the 3D Laser Cutting Robot Market’s progress?

While 3D laser cutting robots outshine in repetitive and high-volume manufacturing, they usually lack flexibility for low-volume or custom production runs. Setting up these systems for short-period manufacturing comprises reprogramming the robot, recalibration, and fixture changes, which can be costly and time-consuming. This restriction hampers the prominence of robotic laser systems in industries like repair workshops, craft manufacturing, or artisan fabrication, where agility is prioritized over automation.

3D Laser Cutting Robot Market: Opportunities

How is the construction and infrastructure boom in developing regions favoring the 3D Laser Cutting Robots Market?

Infrastructure expansion and rapid urbanization, primarily in Southeast Asia, India, and Africa, are driving the demand for steel structures, HVAC systems, custom architectural designs, and pre-engineered buildings. 3D laser cutting robots offer the capability to fabricate complex metal geometries with higher accuracy and speed than manual procedures.

According to the World Bank, more than $2.4 trillion in infrastructure investments are projected in emerging nations by 2030. This generates significant opportunities for the producers of automated cutting systems used in panels, beams, and façade elements, thus impacting the 3D laser cutting robot industry.

3D Laser Cutting Robot Market: Challenges

Energy consumption and environmental concerns restrict the market growth

3D laser cutting systems, especially those using CO2 lasers (≥ 5 kW) or those with high-power fiber, require efficient fume extraction systems and are energy-intensive. The increasing scrutiny of energy and carbon emissions presents a challenge for broader deployment.

In energy-sensitive industries, such as those in the EU, a stringent regulatory framework, including the EcoDesign Directive and the EU Green Deal, is compelling producers to reduce their carbon footprints, presenting investment hurdles and compliance challenges for heavy laser installations.

3D Laser Cutting Robot Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | 3D Laser Cutting Robot Market |

| Market Size in 2024 | USD 310.76 Million |

| Market Forecast in 2034 | USD 570.52 Million |

| Growth Rate | CAGR of 7.89% |

| Number of Pages | 211 |

| Key Companies Covered | ABB Ltd., FANUC Corporation, Yaskawa Electric Corporation, KUKA AG, Mitsubishi Electric Corporation, Coherent Corp., Han's Laser Technology Industry Group Co. Ltd., IPG Photonics Corporation, Amada Co. Ltd., Mazak Optonics Corporation, Jenoptik AG, Bystronic Group, Prima Industrie S.p.A., DNE Laser, Nukon Lasers, and others. |

| Segments Covered | By Type, By Function, By Application, By End-User Industry, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

3D Laser Cutting Robot Market: Segmentation

The global 3D laser cutting robot market is segmented based on type, function, application, end-user industry, and region.

Based on type, the global 3D laser cutting robot industry is divided into fiber laser robots, CO2 laser robots, Nd (Neodymium-doped Yttrium Aluminum Garnet), and others. The fiber laser robot segment held a substantial market share due to its high-class cutting speed, low maintenance costs, and energy efficiency.

On the other hand, the CO₂ laser robots segment ranks second. They are highly preferred for cutting non-metallic materials, such as plastics, glass, and wood.

Based on function, the global market is segmented into cutting, welding, drilling, engraving, and others. The cutting segment dominates the global market, fueled by its extensive use in aerospace, automotive, and industrial machinery sectors.

Conversely, the welding segment holds a second-leading share, backed by its vital role in assembling parts for the shipbuilding, automotive, and heavy equipment industries.

Based on application, the global 3D laser cutting robot market is segmented as automotive, aerospace & defense, consumer electronics, medical devices, industrial manufacturing, and others. The automotive category holds a substantial market share due to high demand for fast, precise, and repeatable cutting-edge body panels, EV battery components, and exhaust systems.

However, the aerospace & defense segment is projected to grow considerably due to its need for high-strength and lightweight materials, such as composites and titanium.

Based on end-user industry, the global market is segmented as the automotive industry, aerospace industry, electronics and semiconductor industry, medical device industry, heavy machinery industry, and others. The automotive industry is the leading segment in the global market, driven by surging demand for precision in chassis and body components, high production volumes, and increasing EV manufacturing.

The aerospace industry segment also dominates after the automotive industry, fueled by its ultra-precise cutting of composite materials and light metals.

3D Laser Cutting Robot Market: Regional Analysis

Asia Pacific to witness significant growth over the forecast period

The Asia Pacific is projected to maintain its dominant position in the global 3D laser cutting robot market, driven by its strong manufacturing base, rapid industrial automation, and the availability of low-cost, skilled labor. APAC comprises leading manufacturing powerhouses, including South Korea, China, and Japan, which dominate various sectors. These nations are key adopters of 3D laser cutting robots to enhance production efficacy and accuracy. The region is witnessing an increase in automation, driven by government initiatives and investments in Industry 4.0. This growth encompasses robotic laser systems, enhancing the regional dominance of smart manufacturing.

Furthermore, while labor costs are lower in the APAC region, it also boasts a growing pool of technically proficient workers, primarily in India and China. This allows easy deployment, maintenance, and operation of robotic systems. Additionally, mature industrial zones and supply chains facilitate the installation of large-scale robots at a low total cost of ownership.

What factors will help Europe to maintain its position in the global 3D laser cutting robot industry?

Europe maintains its position as the second-largest region in the global 3D laser cutting robot industry, thanks to the strong presence of industrial and automotive giants, technological leadership, and the accelerated adoption of digital manufacturing and Industry 4.0. Europe is home to prominent automakers such as Mercedes, BMW, Volkswagen, Stellantis, and Daimler (formerly known as Benz).

These companies depend heavily on laser robots for accurate cutting, chassis components, and EV battery trays. Moreover, European companies are pioneers in laser optics, robotics, and automation solutions. Companies such as KUKA, Trumpf, and ABB are at the forefront of advancements in high-accuracy laser cutting.

Region's focus on quality manufacturing fuels the demand for superior 3D laser cutting robots. Additionally, Europe has adopted Industry 4.0 principles with enthusiasm, backed by European Union programs such as 'Made in Europe' and 'Horizon Europe.' These encourage robotics, digitalization, and smart factory infrastructure.

3D Laser Cutting Robot Market: Competitive Analysis

The leading players in the global 3D laser cutting robot market are:

- ABB Ltd.

- FANUC Corporation

- Yaskawa Electric Corporation

- KUKA AG

- Mitsubishi Electric Corporation

- Coherent Corp.

- Han's Laser Technology Industry Group Co. Ltd.

- IPG Photonics Corporation

- Amada Co. Ltd.

- Mazak Optonics Corporation

- Jenoptik AG

- Bystronic Group

- Prima Industrie S.p.A.

- DNE Laser

- Nukon Lasers

3D Laser Cutting Robot Market: Key Market Trends

Integration of machine learning and AI in laser robots:

AI-based algorithms are now enhancing cutting paths, anticipating maintenance needs, and improving quality control. These smart systems adapt to material variations in real-time, enhancing uptime and reducing wastage. This trend is driving productivity and accuracy in different industries.

Shift toward modular and compact robotic designs:

Vendors are developing modular and more miniature 3D laser cutting robots that can be easily integrated into flexible or space-constrained manufacturing lines. These systems are suitable for tier-2 suppliers and SMEs. This trend denotes a shift towards agile and decentralized production setups.

The global 3D laser cutting robot market is segmented as follows:

By Type

- Fiber Laser Robots

- CO2 Laser Robots

- Nd (Neodymium-doped Yttrium Aluminum Garnet)

- Others

By Function

- Cutting

- Welding

- Drilling

- Engraving

- Others

By Application

- Automotive

- Aerospace & Defense

- Consumer Electronics

- Medical Devices

- Industrial Manufacturing

- Others

By End-User Industry

- Automotive Industry

- Aerospace Industry

- Electronics and Semiconductor Industry

- Medical Device Industry

- Heavy Machinery Industry

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

A 3D laser cutting robot is a dedicated industrial system that integrates robotic arms with high-accuracy laser cutting technology to process complex 3D components. These robots are extensively used in industries such as metal fabrication, automotive, and aerospace for various purposes due to their high accuracy, speed, and flexibility.

The global 3D laser cutting robot market is projected to grow due to the growth of the sheet material fabrication industry, rising demand for high-precision cutting processes, and improvements in robotics and laser sources.

According to study, the global 3D laser cutting robot market size was worth around USD 310.76 million in 2024 and is predicted to grow to around USD 570.52 million by 2034.

The CAGR value of the 3D laser cutting robot market is expected to be approximately 7.89% from 2025 to 2034.

Asia Pacific is expected to lead the global 3D laser cutting robot market during the forecast period.

Technological advancements, including real-time monitoring, AI integration, and multi-axis control, have significantly enhanced the speed, precision, and automation capabilities of these robots. These advancements are fueling the adoption in diverse sectors for high-volume and complex production.

The 3D laser cutting robot market is experiencing a gradual drop in average unit prices due to improvements in manufacturing efficiency and elevated competition among major industry players. However, prices for high-end models with fiber lasers, AI, and multi-axis capabilities remain premium due to their customization features and superior performance.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed