Mechanical Seals Market Size, Share, Trends, Growth & Forecast 2034

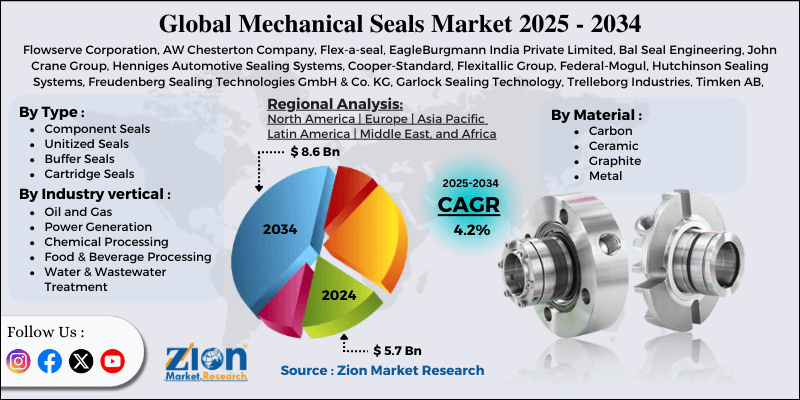

Mechanical Seals Market By Type (Component Seals, Unitized Seals, Buffer Seals, and Cartridge Seals), By Material (Carbon, Ceramic, Graphite, and Metal), By Industry Vertical (Oil and Gas, Power Generation, Chemical Processing, Food and Beverage Processing, and Water and Wastewater Treatment), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

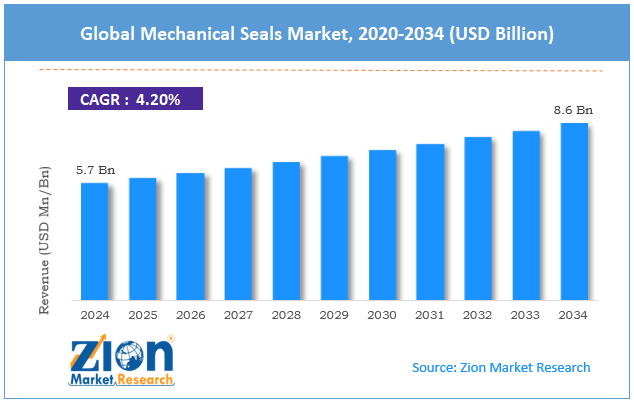

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 5.7 Billion | USD 8.6 Billion | 4.2% | 2024 |

Mechanical Seals Industry Perspective:

The global mechanical seals market size was worth around USD 5.7 billion in 2024 and is predicted to grow to around USD 8.6 billion by 2034, with a compound annual growth rate (CAGR) of roughly 4.2% between 2025 and 2034.

Key Insights

- As per the analysis shared by our research analyst, the global mechanical seals market is estimated to grow annually at a CAGR of around 4.2% over the forecast period (2025-2034).

- In terms of revenue, the global mechanical seals market size was valued at around USD 5.7 billion in 2024 and is projected to reach USD 8.6 billion by 2034.

- Growing demand from the end-use sector is expected to drive the mechanical seals market over the forecast period.

- Based on the type, the cartridge seals segment is expected to capture the largest market share over the projected period.

- Based on the material, the graphite segment is expected to capture the largest market share over the projected period.

- Based on the industry vertical, the oil and gas segment is expected to capture the largest market share over the projected period.

- Based on region, North America is expected to dominate the market during the forecast period.

Mechanical Seals Market: Overview

Mechanical seals are instruments that prevent fluids (liquids or gases) from leaking when a rotating shaft passes through a stationary housing or container, as in pumps, compressors, or mixers. They seal this contact so that the fluid doesn't leak out or get dirty. There are two highly flat, glossy surfaces on a mechanical seal called seal faces. One of these surfaces moves with the shaft, while the other stays fixed in the housing. The faces are forced together, and a thin layer of fluid keeps them cold and lubricated. This helps the seal work and stops damage. Springs or bellows push on the faces to keep them in contact, regardless of pressure, temperature, or shaft movement. This is how sealing that change works. There are various kinds of mechanical seals.

For instance, single seals have one face pair, whereas double seals have two face pairs and a barrier fluid for further protection. They are necessary to ensure that industrial equipment that handles fluids doesn't leak, works properly, and stays in good condition.

Mechanical Seals Market Dynamics

Growth Drivers

How do rising industrialization & infrastructure development propel the mechanical seals industry growth?

The mechanical seals business is primarily driven by industrialization and infrastructure development. Rapid urbanization and industrial growth are making it increasingly crucial that machinery used in manufacturing, chemical processing, oil and gas, power generation, and water treatment have reliable, effective sealing solutions. As companies grow and modernize, the need for high-performance mechanical seals capable of handling sophisticated, high-pressure, and high-temperature applications rises rapidly.

As more businesses adopt automation and intelligent manufacturing systems, they need more mechanical seals to keep systems safe and reduce maintenance requirements. Infrastructure growth, especially in places like China, India, and the Asia-Pacific region, as these regions become more prosperous, requires significant investment in energy projects, water management, and city utilities. Pumps, compressors, turbines, and other machines that spin require long-lasting seals. Mechanical seals are necessary for the successful completion and long-term viability of large-scale infrastructure projects because they help prevent leaks, ensure proper operation, and safeguard the environment.

For instance, the total infrastructure investment in India has significantly increased, with public and private sector contributions shaping the growth trajectory. India's total infrastructure spending has grown exponentially, with budget allocations rising to ₹10 lakh crore in 2023-24.

Restraints

Does the high initial cost of advanced seals impede the growth of the mechanical seals market?

The high initial cost of complex mechanical seals makes it difficult for the sector to thrive, as it requires significant upfront investment in materials, design, and production accuracy. Advanced seals sometimes use high-performance materials like ceramics, silicon carbide, and certain metal alloys. These materials make the seals last longer and work better, but they also make them much more expensive to produce.

Also, sophisticated designs, such as multiple or custom-made seals for specific industrial applications, increase the overall starting cost. Many small and medium-sized firms (SMEs) and cost-sensitive industries may not be willing or able to use premium sealing systems due to the high initial cost, even though they may benefit in the long run. Also, modern mechanical seals often require professional installation and maintenance, making them more expensive, more complex to use, and harder for more people to use.

Opportunities

Will the innovative product launch offer a potential opportunity for the mechanical seals industry's growth?

The mechanical seals industry has ample opportunities to grow through new product introductions. New materials, designs, and technologies, such as AI-enabled smart seals that can monitor in real time and forecast when maintenance is needed, are changing the industry by making seals work better, last longer, and use less energy. These improvements help reduce downtime, maintenance costs, and the risk of leaks, while also meeting the growing need for high-performance sealing solutions across many other fields.

For instance, in September 2025, John Crane released the Type 8628VL, a next-generation mechanical seal made to solve the oil and gas industry's most challenging problems: keeping seals intact in pipelines that carry both ethane and ethylene. The Type 8628VL is designed to operate in very hot and cold conditions and features spiral-groove non-contacting technology to ensure greater reliability, efficiency, and environmental friendliness.

Challenges

Requirement for skilled installation & maintenance poses a major challenge to market expansion

One major obstacle to the sector's expansion is that mechanical seals are technically complex and require installation and maintenance by experts. To do a decent job, it's necessary to ensure everything is in the appropriate spot, pick the right type and material for the seal, and make sure the parts fit together well. To perform maintenance correctly, it's essential to know how to inspect for leaks, detect seal wear, and make replacements without damaging the equipment or slowing down operations. There aren't enough skilled workers who know how to do this, which increases the likelihood that installations and repairs will go wrong. This can lead to early seal failure and higher operating expenses.

Mechanical Seals Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Mechanical Seals Market |

| Market Size in 2024 | USD 5.7 Billion |

| Market Forecast in 2034 | USD 8.6 Billion |

| Growth Rate | CAGR of 4.2% |

| Number of Pages | 215 |

| Key Companies Covered | Flowserve Corporation, AW Chesterton Company, Flex-a-seal, EagleBurgmann India Private Limited, Bal Seal Engineering, John Crane Group, Henniges Automotive Sealing Systems, Cooper-Standard, Flexitallic Group, Federal-Mogul, Hutchinson Sealing Systems, Freudenberg Sealing Technologies GmbH & Co. KG, Garlock Sealing Technology, Trelleborg Industries, Timken AB, Dana Corporation, and others. |

| Segments Covered | By Type, By Material, By Industry vertical, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Mechanical Seals Market: Segmentation

The global mechanical seals industry is segmented based on type, material, industry vertical, and region.

Based on the type, the global mechanical seals market is bifurcated into component seals, unitized seals, buffer seals, and cartridge seals. The cartridge seals segment is expected to dominate the market. Cartridge seals' sales growth is driven by their design advantages, such as pre-assembled pieces that reduce installation errors and downtime during maintenance. This efficiency attracts businesses that value operational reliability, such as chemical processing, oil and gas, water treatment, and power production.

Based on the material, the global mechanical seals industry is bifurcated into carbon, ceramic, graphite, and metal. The graphite segment holds the major market share. Graphite is preferred for mechanical seals due to its superior thermal stability, chemical resistance, and self-lubricating properties, making it suitable for tough industrial applications such as chemical processing, oil and gas, and power generation.

Based on the industry vertical, the global mechanical seals market is divided into oil and gas, power generation, chemical processing, food and beverage processing, and water and wastewater treatment. The oil and gas segment is expected to dominate the market over the forecast period. This expansion is driven by the industry's critical need for reliable, leakproof sealing solutions for the exploration, extraction, refining, transportation, and marketing of oil and gas products. Mechanical seals are critical for preventing hazardous fluid and gas leaks, maintaining operational safety, reducing environmental impacts, and meeting strict industry requirements.

Regional Analysis

Will North America dominate the mechanical seals market over the projected period?

The North America region is expected to dominate the mechanical seals market over the analysis period. The area is booming because the oil and gas, chemical, and water treatment industries are all doing well. Regulatory frameworks that promote safety and efficiency in industrial processes facilitate market expansion. The United States is the biggest donor, followed by Canada, where industrial activity and infrastructure development are both on the rise. Some of the major corporations that shape North America's competitive landscape are Flowserve, Parker Hannifin, and John Crane. These companies are investing in research and development to develop new concepts and improve their products. The market is also shifting toward newer materials and technology that will make seals last longer and work better. Because of this competitive environment, businesses must continually improve and satisfy customers to maintain a strong market position.

For instance, in June 2025, John Crane, a global leader in rotating equipment solutions and a business of Smiths Group plc, announced the launch of the Type 93AX Coaxial Separation Seal – a next-generation dry gas sealing solution engineered to help customers reduce emissions, improve equipment reliability, and lower operational costs.

Mechanical Seals Market: Competitive Analysis

The global mechanical seals market is dominated by players like:

- Flowserve Corporation

- AW Chesterton Company

- Flex-a-seal

- EagleBurgmann India Private Limited

- Bal Seal Engineering

- John Crane Group

- Henniges Automotive Sealing Systems

- Cooper-Standard

- Flexitallic Group

- Federal-Mogul

- Hutchinson Sealing Systems

- Freudenberg Sealing Technologies GmbH & Co. KG

- Garlock Sealing Technology

- Trelleborg Industries

- Timken AB

- Dana Corporation

The global mechanical seals market is segmented as follows:

By Type

- Component Seals

- Unitized Seals

- Buffer Seals

- Cartridge Seals

By Material

- Carbon

- Ceramic

- Graphite

- Metal

By Industry vertical

- Oil and Gas

- Power Generation

- Chemical Processing

- Food and Beverage Processing

- Water and Wastewater Treatment

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed