Global Light Industrial Conveyor Belts Market Size, Share, Growth Analysis Report - Forecast 2034

Light Industrial Conveyor Belts Market By Material Type (Polyester, Nylon, Rubber, Polypropylene, Composite Materials), By Belt Type (Flat Belts, Modular Belts, Roller Bed Belts, Incline/Decline Belts, Wire Mesh Belts), By Application (Food Processing, Packaging, Automotive Assembly, Pharmaceuticals, Electronics), By Load Capacity (Light Load Capacity (up to 50 lbs), Medium Load Capacity (51-150 lbs), Heavy Load Capacity (151-300 lbs)), By Functionality (Transporting, Sorting, Assembly, Storage, Universal Applications), and By Region: Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025-2034

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

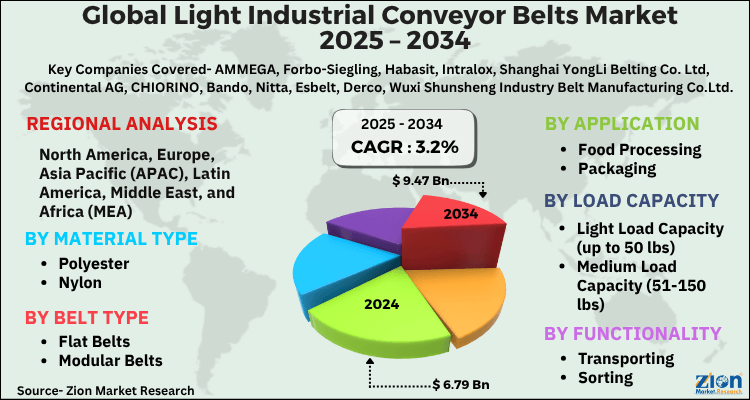

| USD 6.79 Billion | USD 9.47 Billion | 3.2% | 2024 |

Light Industrial Conveyor Belts Market Size:

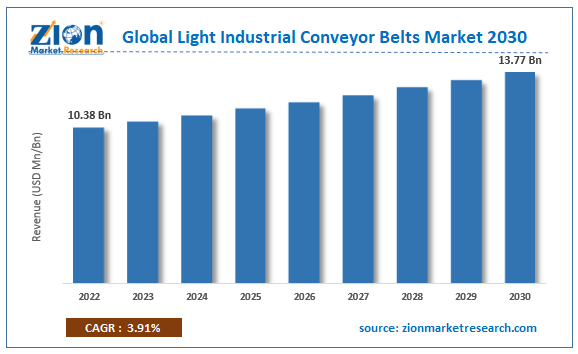

The global light industrial conveyor belts market size was worth around USD 6.79 Billion in 2024 and is predicted to grow to around USD 9.47 Billion by 2034 with a compound annual growth rate (CAGR) of roughly 3.2% between 2025 and 2034. The report analyzes the global light industrial conveyor belts market's drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the light industrial conveyor belts industry.

Light Industrial Conveyor Belts Market: Overview

Light industrial conveyor belts are essential components within the manufacturing, food processing, warehousing, and packaging industries, facilitating the seamless movement of materials, products, and components. Constructed from materials like rubber, PVC, and polyurethane, they come in various types, including flat, modular, and roller conveyors, serving diverse applications like assembly lines, material handling, and distribution systems. Their role in enhancing efficiency, automation, and streamlined processes underscores their significance in optimizing production and logistics operations.

Key Insights

- As per the analysis shared by our research analyst, the global light industrial conveyor belts market is estimated to grow annually at a CAGR of around 3.2% over the forecast period (2025-2034).

- Regarding revenue, the global light industrial conveyor belts market size was valued at around USD 6.79 Billion in 2024 and is projected to reach USD 9.47 Billion by 2034.

- The light industrial conveyor belts market is projected to grow at a significant rate due to increasing automation in manufacturing, e-commerce growth, demand for efficient material handling, and advancements in lightweight, durable conveyor belt technologies.

- Based on Material Type, the Polyester segment is expected to lead the global market.

- On the basis of Belt Type, the Flat Belts segment is growing at a high rate and will continue to dominate the global market.

- Based on the Application, the Food Processing segment is projected to swipe the largest market share.

- By Load Capacity, the Light Load Capacity (up to 50 lbs) segment is expected to dominate the global market.

- In terms of Functionality, the Transporting segment is anticipated to command the largest market share.

- Based on region, Asia-Pacific is predicted to dominate the global market during the forecast period.

Light Industrial Conveyor Belts Market: Growth Drivers

Growing demand for streamlined belt material handling systems to drive market growth during the forecast period.

In today's fast-paced industrial landscape, the need for streamlined belt material handling processes has become paramount. This requirement arises from the pursuit of heightened operational efficiency and reduced costs across manufacturing, distribution, and logistics sectors. Traditional manual handling methods are prone to delays, errors, and inefficiencies, which can lead to production bottlenecks and increased expenses. Streamlined belt material handling, facilitated by technologies like light industrial conveyor belts, optimizes the movement of goods by minimizing manual interventions and enhancing the seamless flow of items. These conveyor systems automate the transfer of belt materials, components, and products, accelerating processes, lowering the risk of errors, and enabling businesses to meet the demands of competitive markets with agility and precision. Owing to this demand spurred for a streamlined belt material handling system, the growth of the global light industrial conveyor belts market is projected to spur during the forecast period.

Light Industrial Conveyor Belts Market: Restraints

High initial capital investment and maintenance cost is the biggest hurdle to the market expansion

A key growth restriction in the light industrial conveyor belts market is the substantial initial capital investment required for their implementation. While these conveyor systems yield long-term advantages in terms of streamlined operations, enhanced efficiency, and reduced labor costs, the upfront expenses can be daunting for businesses, particularly smaller enterprises with limited financial resources. The acquisition cost encompasses not only the conveyor equipment itself but also installation, integration with existing systems, and potential modifications to facility layouts. As a result, the perceived high entry barrier might dissuade some companies from embracing this technology, impeding market growth, especially within budget-constrained sectors.

Moreover, the investment challenge is amplified by the need for customization and maintenance. Each industry has distinct requirements that necessitate tailored conveyor solutions, leading to potentially higher costs and longer lead times. As industries evolve, seeking to optimize their processes and remain competitive, the tension between the cost of implementation and the long-term benefit of operational efficiency becomes a critical factor influencing adoption decisions. Addressing this challenge may involve strategies such as offering flexible financing options, emphasizing long-term cost savings, and providing comprehensive consulting services to showcase the value proposition of light industrial conveyor belts in enhancing overall business performance.

Light Industrial Conveyor Belts Market: Opportunities

Increasing integration of automation and Industry 4.0 technologies across industries to provide growth opportunities

As industries undergo transformative shifts toward enhanced operational efficiency and data-driven decision-making, conveyor systems are positioned as essential components in achieving these goals. By incorporating advanced sensors, Internet of Things (IoT) devices, and real-time connectivity, conveyor belts can be optimized for intelligent belt material handling within the context of smart factory environments.

Conveyor systems equipped with Industry 4.0 capabilities enable real-time monitoring, data collection, and analysis of belt material movement. This integration empowers businesses to implement predictive maintenance strategies, identify operational inefficiencies, and enhance overall production processes. The data-driven insights garnered from smart conveyor belts facilitate informed decision-making, reduce downtime through proactive maintenance, and contribute to resource optimization. As industries increasingly adopt automation and digital transformation, the demand for these technologically advanced conveyor systems is poised to grow, making them a pivotal driver in shaping the future of efficient and interconnected manufacturing processes.

Light Industrial Conveyor Belts Market: Challenges

Competition from alternative solutions to challenge market cap growth

Robotic solutions, for instance, provide the versatility to handle a wide array of tasks with dynamic programming and can be reconfigured for different production needs. Autonomous vehicles and drones offer mobility across varied terrains, making them particularly valuable in environments where conveyor belts are impractical. Additionally, these alternatives can be integrated into existing systems with relative ease, which can be an attractive proposition for businesses looking for agile automation solutions. To address this challenge, the light industrial conveyor belts industry must focus on demonstrating their own advantages and adaptability. Manufacturers need to emphasize the efficiency, reliability, and established track record of conveyor systems in belt material handling, showcasing their capacity to handle a variety of loads and applications. By highlighting how conveyor belts excel in repetitive tasks, large-scale belt material transport, and structured workflows, the market can underscore their significance in achieving consistent and standardized operations. Furthermore, offering hybrid solutions that integrate conveyor systems with robotic or autonomous components can capitalize on the strengths of both technologies, providing a comprehensive solution that addresses the evolving needs of industries seeking efficient belt material handling methods.

Light Industrial Conveyor Belts Market: Segmentation

The global light industrial conveyor belts market is segmented based on Material Type, Belt Type, Application, Load Capacity, Functionality, and region.

Based on Material Type, the global light industrial conveyor belts market is divided into Polyester, Nylon, Rubber, Polypropylene, Composite Materials.

On the basis of Belt Type, the global light industrial conveyor belts market is bifurcated into Flat Belts, Modular Belts, Roller Bed Belts, Incline/Decline Belts, Wire Mesh Belts.

By Application, the global light industrial conveyor belts market is split into Food Processing, Packaging, Automotive Assembly, Pharmaceuticals, Electronics.

In terms of Load Capacity, the global light industrial conveyor belts market is categorized into Light Load Capacity (up to 50 lbs), Medium Load Capacity (51-150 lbs), Heavy Load Capacity (151-300 lbs).

By Functionality, the global Light Industrial Conveyor Belts market is divided into Transporting, Sorting, Assembly, Storage, Universal Applications.

Light Industrial Conveyor Belts Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Light Industrial Conveyor Belts Market |

| Market Size in 2024 | USD 6.79 Billion |

| Market Forecast in 2034 | USD 9.47 Billion |

| Growth Rate | CAGR of 3.2% |

| Number of Pages | 206 |

| Key Companies Covered | AMMEGA, Forbo-Siegling, Habasit, Intralox, Shanghai YongLi Belting Co. Ltd, Continental AG, CHIORINO, Bando, Nitta, Esbelt, Derco, Wuxi Shunsheng Industry Belt Manufacturing Co.Ltd., Volta Belting Technology Ltd., Sparks, Jiangsu New Lianda Belting Technology Co.Ltd., Jiangyin TianGuang Technology Co.Ltd, Mitsuboshi Belting Ltd., and others. |

| Segments Covered | By Material Type, By Belt Type, By Application, By Load Capacity, By Functionality, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2020 to 2024 |

| Forecast Year | 2025 to 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Light Industrial Conveyor Belts Market: Regional Analysis

Asia Pacific to lead the market during the forecast period

The Asia-Pacific region has implicit a prominent position in spearheading the sales and adoption of light industrial conveyor belts. This dominance of the region in the global light industrial conveyor belts market can be attributed to several key factors such as the rapid boom in food & beverage, automobile, and manufacturing sectors. China, with its extensive manufacturing base, has played a pivotal role, showcasing a consistent demand for conveyor systems to facilitate efficient material movement across industries. In fact, China is studied to be the biggest conveyor belt market. China’s F&B industry touched around USD 900 billion in 2022. Also, it is the largest manufacturer of toys, electronic parts, and electric vehicles. Furthermore, Japan and South Korea have contributed significantly due to their advanced technological landscapes and a focus on automation to enhance manufacturing processes. The robust growth in the Asia-Pacific market is underpinned by the region's industrialization drive, rapid urbanization, and increasing labor costs that incentivize businesses to invest in automation for improved productivity. As these countries continue to prioritize technological innovation and infrastructure development, the demand for conveyor systems to streamline material handling processes and support manufacturing growth is expected to persist.

Light Industrial Conveyor Belts Market: Recent Developments

- In March 2023, Intralox, LLC announced plans to invest USD 100 million in a new manufacturing facility in China. The facility is expected to create 500 new jobs.

- In February 2023, Habasit AG partnered with Emerson Process Management to develop a new conveyor belt solution for the food and beverage industry. The solution is said to be more hygienic and efficient than traditional conveyor belts.

- In January 2023, Intralox, LLC partnered with Amazon Robotics to develop a new conveyor belt system for the company's fulfillment centers. The system is said to be more efficient and accurate than traditional conveyor belt systems.

- In January 2023, Ammeraal Beltech partnered with Siemens to develop a new conveyor belt system for the automotive industry. The system is said to be more energy-efficient and sustainable than traditional conveyor belt systems.

Light Industrial Conveyor Belts Market: Competitive Analysis

The report provides a company market share analysis to give a broader overview of the key market players. In addition, the report also covers key strategic developments of the market, including acquisitions & mergers, new product launches, agreements, partnerships, collaborations & joint ventures, research & development, and regional expansion of major participants involved in the light industrial conveyor belts market on a global and regional basis.

The global light industrial conveyor belts market is dominated by players like:

- AMMEGA

- Forbo-Siegling

- Habasit

- Intralox

- Shanghai YongLi Belting Co. Ltd

- Continental AG

- CHIORINO

- Bando

- Nitta

- Esbelt

- Derco

- Wuxi Shunsheng Industry Belt Manufacturing Co.Ltd.

- Volta Belting Technology Ltd.

- Sparks

- Jiangsu New Lianda Belting Technology Co.Ltd.

- Jiangyin TianGuang Technology Co.Ltd

- Mitsuboshi Belting Ltd.

The global light industrial conveyor belts market is segmented as follows;

By Material Type

- Polyester

- Nylon

- Rubber

- Polypropylene

- Composite Materials

By Belt Type

- Flat Belts

- Modular Belts

- Roller Bed Belts

- Incline/Decline Belts

- Wire Mesh Belts

By Application

- Food Processing

- Packaging

- Automotive Assembly

- Pharmaceuticals

- Electronics

By Load Capacity

- Light Load Capacity (up to 50 lbs)

- Medium Load Capacity (51-150 lbs)

- Heavy Load Capacity (151-300 lbs)

By Functionality

- Transporting

- Sorting

- Assembly

- Storage

- Universal Applications

By Region

- North America

- The U.S.

- Canada

- Mexico

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Australia

- South Korea

- Rest of Asia Pacific

- The Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- Kuwait

- South Africa

- Rest of the Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

Table Of Content

Methodology

FrequentlyAsked Questions

Light industrial conveyor belts are essential components within manufacturing, food processing, warehousing, and packaging industries, facilitating the seamless movement of materials, products, and components. Constructed from materials like rubber, PVC, and polyurethane.

The global light industrial conveyor belts market is expected to grow due to rising automation in manufacturing and logistics, the booming e-commerce sector, the growing need for efficient material handling solutions, and continuous technological advancements in belt materials and smart conveyor systems.

According to a study, the global light industrial conveyor belts market size was worth around USD 6.79 Billion in 2024 and is expected to reach USD 9.47 Billion by 2034.

The global light industrial conveyor belts market is expected to grow at a CAGR of 3.2% during the forecast period.

Asia Pacific is expected to dominate the light industrial conveyor belts market over the forecast period.

Leading players in the global light industrial conveyor belts market include AMMEGA, Forbo-Siegling, Habasit, Intralox, Shanghai YongLi Belting Co. Ltd, Continental AG, CHIORINO, Bando, Nitta, Esbelt, Derco, Wuxi Shunsheng Industry Belt Manufacturing Co.Ltd., Volta Belting Technology Ltd., Sparks, Jiangsu New Lianda Belting Technology Co.Ltd., Jiangyin TianGuang Technology Co.Ltd, Mitsuboshi Belting Ltd., among others.

The report explores crucial aspects of the light industrial conveyor belts market, including a detailed discussion of existing growth factors and restraints, while also examining future growth opportunities and challenges that impact the market.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed