Forging Presses Market Size, Growth, Global Trends, Forecast 2034

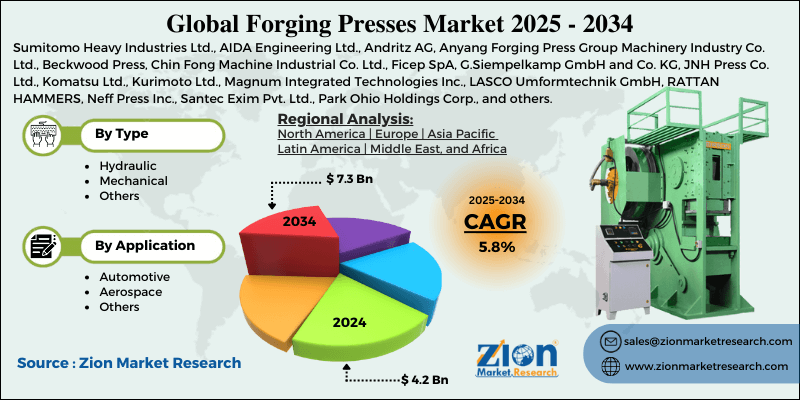

Forging Presses Market By Type (Hydraulic, Mechanical, and Others), By Application (Automotive, Aerospace, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

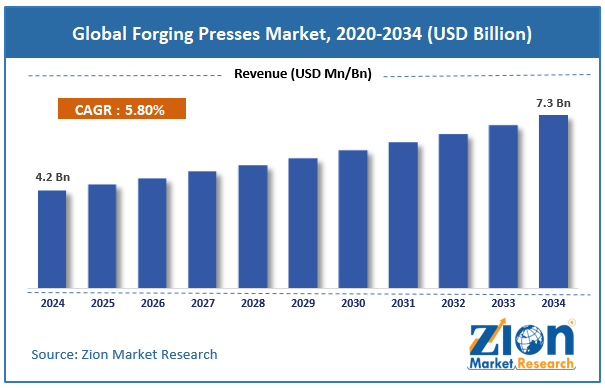

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 4.2 Billion | USD 7.3 Billion | 5.8% | 2024 |

Forging Presses Industry Perspective:

The global forging presses market size was worth around USD 4.2 billion in 2024 and is predicted to grow to around USD 7.3 billion by 2034, with a compound annual growth rate (CAGR) of roughly 5.8% between 2025 and 2034.

Key Insights

- As per the analysis shared by our research analyst, the global forging presses market is estimated to grow annually at a CAGR of around 5.8% over the forecast period (2025-2034).

- In terms of revenue, the global forging presses market size was valued at around USD 4.2 billion in 2024 and is projected to reach USD 7.3 billion by 2034.

- The increasing demand from the end-use industry is expected to drive the forging presses market over the forecast period.

- Based on the type, the hydraulic segment is expected to capture the largest market share over the projected period.

- Based on the application, the automotive segment holds the major market share.

- Based on region, the Asia Pacific is expected to dominate the market during the forecast period.

Forging Presses Market: Overview

Press forging is the process of shaping metal by exerting gradual, controlled pressure between two dies. A forging press is a machine that performs this function. A forging press employs a vertical ram to apply constant force, while drop forging uses repeated impacts. The dies push the metal workpiece into a new shape. This procedure is often used to produce a large number of parts quickly and to strengthen and stabilize the metal by creating a grain flow that forms the part. The market is pushed by increased demand for automobiles, planes, defense, and high-performance applications, as well as technological progress and growth in new industries. however, the hefty costs for capital and upkeep make it hard for the business to grow.

Forging Presses Market Dynamics

Growth Drivers

Why does the rising demand from the automotive sector drive the forging presses market growth?

The market for forging presses is growing quickly, mainly because the auto sector needs more of them. The forging press market is mostly driven by the automobile industry's need for strong, long-lasting, and lightweight parts, such as engine parts, gears, crankshafts, and suspension parts. More automobiles are being made around the world, including classic internal combustion engine vehicles and electric vehicles (EVs). These vehicles need precisely manufactured parts to work better and use less fuel.

For instance, the Society of Indian Automobile Manufacturers reports that overall sales of passenger vehicles increased from 38.90 lakh units in FY 2022-23 to 42.19 lakh units in FY 2023-24. Utility vehicles range in size from 20.04 lakh to 25.21 lakh units, while vans range in size from 1.39 lakh to 1.49 lakh units. Sales of passenger cars went down from 17.47 lakh to 15.49 lakh units in FY 2023–24 compared to the year before. Thus, the aforementioned stats are driving the market growth.

Restraints

Why do the high capital costs & maintenance costs hinder the forging presses market growth?

The forging presses market faces numerous challenges due to the high costs associated with starting up and operating. It costs a lot to buy and set up forging presses, especially complex CNC and hydraulic presses. This may be too much for small and medium-sized firms to handle. Also, the ongoing expenditures are higher since these machines are complicated to use and need specialized skills to operate and maintain. O

verall, the forging presses industry is still not growing as fast as it should because of high capital and maintenance expenses, as well as other challenges, like a lack of educated workers and rigorous rules. But the industry keeps growing because of ongoing technical improvements and rising demand from businesses that employ the products.

Opportunities

How does the rising production capacity of key market players offer a potential opportunity for forging presses industry growth?

Market players in the forging presses industry are actively expanding their production capacity to satisfy the rising demand in various industries, including automotive and aerospace. For instance, in July 2025, Maxiforja begins production on the world's largest forging press, delivered by ANDRITZ Schuler and equipped with the Kinetic Energy Recovering System. In order to increase production capacity for huge knuckles weighing up to 40 kg, the business has installed a record-breaking 6,500-ton forging press from ANDRITZ Schuler, which is now operational. ANDRITZ Schuler's Italian subsidiary, ANDRITZ Farina, designed the GLK 6500 press, which was wholly produced at the Prensas Schuler plant in Brazil. Aside from KERS, the series includes a Scotch Yoke that works directly in the slide, allowing for a more compact design and higher part accuracy. Maxiforja already has forging presses ranging from 800 to 4,000 tons, but for the first time, it decided to invest in ANDRITZ Schuler technology.

Challenges

Why do the energy consumption & operational cost pose a major challenge to market expansion?

Forging presses are well-known for their high energy consumption and maintenance requirements, which greatly increase operational expenses. Traditional forging presses, particularly hydraulic models, consume a significant amount of electricity while operating, as they generate a substantial force for metal deformation. Energy consumption is normally highest during the press's main stroke phases and when maintaining hydraulic pressure.

Modern forging presses, on the other hand, are increasingly constructed with energy economy in mind, with features like energy recovery systems, flywheel energy storage, and improved motor control technologies that help reduce peak power demands and overall electricity consumption. Furthermore, operating costs may provide a significant barrier to industry growth. These costs include energy, routine maintenance, part replacement, and labor for professional operators and maintenance personnel.

Forging Presses Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Forging Presses Market |

| Market Size in 2024 | USD 4.2 Billion |

| Market Forecast in 2034 | USD 7.3 Billion |

| Growth Rate | CAGR of 5.8% |

| Number of Pages | 215 |

| Key Companies Covered | Sumitomo Heavy Industries Ltd., AIDA Engineering Ltd., Andritz AG, Anyang Forging Press Group Machinery Industry Co. Ltd., Beckwood Press, Chin Fong Machine Industrial Co. Ltd., Ficep SpA, G.Siempelkamp GmbH and Co. KG, JNH Press Co. Ltd., Komatsu Ltd., Kurimoto Ltd., Magnum Integrated Technologies Inc., LASCO Umformtechnik GmbH, RATTAN HAMMERS, Neff Press Inc., Santec Exim Pvt. Ltd., Park Ohio Holdings Corp., and others. |

| Segments Covered | By Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Forging Presses Market: Segmentation

The global forging presses industry is segmented based on type, application, and region.

Based on the type, the global forging presses market is bifurcated into hydraulic, mechanical, and others. The hydraulic segment is expected to capture the largest market share over the projected period. The growth of the segment is attributed to the increasing demand for high-strength, lightweight materials. Automotive (particularly EVs), aerospace, and defense industries are rapidly utilizing complex alloys and materials (high-strength steel, aluminum, titanium, and so on) that require the precision and power of hydraulic presses. The goal is to create lighter parts (for fuel/energy efficiency) while meeting strong safety standards. Hydraulic forging presses are ideal for this.

Based on the application, the global forging presses industry is bifurcated into automotive, aerospace, and others. The automotive segment holds the major market share. This growth is attributed to the rising demand for EVs. EVs require components that differ from regular ICE vehicles (battery housings, electric motors, lighter frames, etc.). Many of these necessitate forged components with precise tolerances and strength. Weight savings also benefit EVs more (both in terms of performance and range). As a result, investments are being made in forging presses designed for these applications.

Forging Presses Market: Regional Analysis

Why does the Asia Pacific dominate the forging presses market over the projected period?

The Asia Pacific is expected to dominate the global forging presses market over the projected period. Growing industrialization, a stronger automotive and manufacturing sector, and massive infrastructure development throughout the region are all contributing to a boost in regional revenue. According to certain sources, China's automobile sector is doing very well, largely because sales of New Energy Vehicles (NEVs) have gone up. In the first eight months of 2025, NEV sales reached 9.62 million units. The number of cars sold is also going up.

By August 2025, 21.13 million cars are expected to be sold, representing a 12.6% increase from the previous year. Chinese companies are taking over the passenger vehicle market, with a 66% market share by March 2025. The country is also the world's biggest supplier of cars. Thus, the aforementioned stats are expected to fuel the industry expansion.

Forging Presses Market: Competitive Analysis

The global forging presses market is dominated by players like:

- Sumitomo Heavy Industries Ltd.

- AIDA Engineering Ltd.

- Andritz AG

- Anyang Forging Press Group Machinery Industry Co. Ltd.

- Beckwood Press

- Chin Fong Machine Industrial Co. Ltd.

- Ficep SpA

- G.Siempelkamp GmbH and Co. KG

- JNH Press Co. Ltd.

- Komatsu Ltd.

- Kurimoto Ltd.

- Magnum Integrated Technologies Inc.

- LASCO Umformtechnik GmbH

- RATTAN HAMMERS

- Neff Press Inc.

- Santec Exim Pvt. Ltd.

- Park Ohio Holdings Corp.

The global forging presses market is segmented as follows:

By Type

- Hydraulic

- Mechanical

- Others

By Application

- Automotive

- Aerospace

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Press forging is the process of shaping metal by exerting gradual, controlled pressure between two dies. A forging press is a machine that performs this function. A forging press employs a vertical ram to apply constant force, while drop forging uses repeated impacts.

The forging presses market is being pushed by increased demand for automobiles, planes, defense, and high-performance applications, as well as technological progress and growth in new industries.

The high initial and operational cost is a major challenge for forging presses industry expansion.

Based on the application, the automotive segment is expected to dominate the industry growth during the projected period.

The increasing production capacity by the key market players and technological advancements pose a major impact factor for the industry growth over the projected period.

According to the report, the global forging presses market size was worth around USD 4.2 billion in 2024 and is predicted to grow to around USD 7.3 billion by 2034.

The global forging presses market is expected to grow at a CAGR of 5.8% during the forecast period.

The global forging presses industry growth is expected to be driven by the Asia Pacific region. It is currently the world’s highest-revenue-generating market, driven by the presence of major players and increasing demand from the end-use sector.

The global forging presses market is dominated by players like Sumitomo Heavy Industries Ltd., AIDA Engineering Ltd., Andritz AG, Anyang Forging Press Group Machinery Industry Co. Ltd., Beckwood Press, Chin Fong Machine Industrial Co. Ltd., Ficep SpA, G.Siempelkamp GmbH and Co. KG, JNH Press Co. Ltd., Komatsu Ltd., Kurimoto Ltd., Magnum Integrated Technologies Inc., LASCO Umformtechnik GmbH, RATTAN HAMMERS, Neff Press Inc., Santec Exim Pvt. Ltd., and Park Ohio Holdings Corp., among others.

The forging presses market report covers the geographical market along with a comprehensive competitive landscape analysis. It also includes cash flow analysis, profit ratio analysis, market basket analysis, market attractiveness analysis, sentiment analysis, PESTLE analysis, trend analysis, SWOT analysis, trade area analysis, demand & supply analysis, Porter’s five forces analysis, and value chain analysis.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed