Global Spraying Nozzles Market Size, Share, Growth Analysis Report - Forecast 2034

Spraying Nozzles Market By Type (Padded, Non-padded), By Application (Seamed, Seamless), and By Region: Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

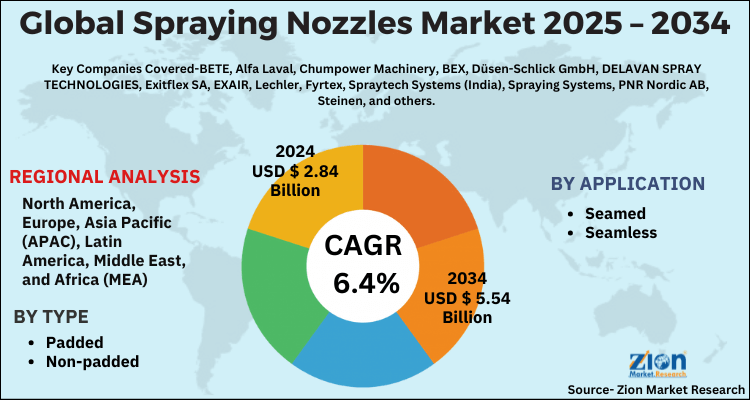

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 2.84 Billion | USD 5.54 Billion | 6.4% | 2024 |

Spraying Nozzles Market: Industry Perspective

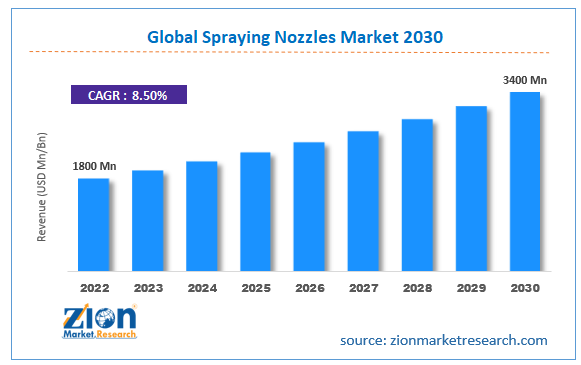

The global spraying nozzles market size was worth around USD 2.84 Billion in 2024 and is predicted to grow to around USD 5.54 Billion by 2034 with a compound annual growth rate (CAGR) of roughly 6.4% between 2025 and 2034. The report analyzes the global spraying nozzles market's drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the spraying nozzles industry.

Spraying Nozzles Market: Overview

A device that helps a liquid disperse by creating a spray is known as a spray nozzle or an atomizer. To create a spray, liquid structures like liquid sheets or ligaments must be broken up into droplets, frequently by employing kinetic energy to offset the expense of adding more surface area. Many different types of spray nozzles employ one or more liquid breakup processes. These mechanisms may be categorized into three groups: liquid sheet breakup, jets, and capillary waves. When a spray nozzle is built to have the proper spray properties, it is crucial for many applications.

Key Insights

- As per the analysis shared by our research analyst, the global spraying nozzles market is estimated to grow annually at a CAGR of around 6.4% over the forecast period (2025-2034).

- Regarding revenue, the global spraying nozzles market size was valued at around USD 2.84 Billion in 2024 and is projected to reach USD 5.54 Billion by 2034.

- The spraying nozzles market is projected to grow at a significant rate due to rising demand in agriculture, automotive, and manufacturing sectors, technological advancements in precision spraying, and increasing focus on efficient resource utilization.

- Based on Type, the Padded segment is expected to lead the global market.

- On the basis of Application, the Seamed segment is growing at a high rate and will continue to dominate the global market.

- Based on region, North America is predicted to dominate the global market during the forecast period.

Spraying Nozzles Market: Dynamics

Key Growth Drivers:

The spraying nozzles market is propelled by expanding agricultural activities and the increasing adoption of precision farming techniques that require efficient, uniform spray application to maximize crop yields. Growth is also driven by rising demand in industrial applications—such as coating, cooling, and cleaning—in sectors like automotive, chemical processing, and food & beverage, where optimized fluid distribution improves process efficiency. Technological advancements in nozzle design and materials (wear-resistant alloys, ceramics, and polymers) that extend service life and reduce downtime further stimulate market growth. Additionally, stricter environmental and safety regulations encouraging reduced chemical use and drift mitigation boost demand for high-precision, low-drift nozzles.

Restraints:

Market expansion is constrained by the high initial cost of advanced, precision-engineered nozzles and related monitoring systems, which can deter small-scale farmers and low-margin industrial users. Inconsistent quality and performance among low-cost, unbranded nozzles available in some regions lead to reliability concerns and limit adoption of better-performing alternatives. Maintenance needs—such as clogging from particulates and wear from abrasive fluids—raise operational costs and reduce the perceived value of upgrades for budget-conscious buyers. Fragmented procurement channels and lack of standardized testing protocols in certain markets also hinder wide-scale deployment.

Opportunities:

There are strong opportunities in smart agriculture and IoT-enabled spraying systems that integrate flow sensors, GPS, and variable-rate application control to optimize input use and lower operational costs. Growing urbanization and expansion of commercial landscaping and green infrastructure create new demand pockets for specialized nozzles designed for turf care and ornamental spraying. Emerging markets investing in mechanization present opportunities for international manufacturers to introduce durable, low-maintenance nozzle solutions. Innovations in anti-drip, self-cleaning, and corrosion-resistant nozzle technologies can unlock cross-industry adoption and aftermarket service revenues.

Challenges:

Key challenges include the need to continuously innovate while keeping manufacturing costs competitive, since customers often prioritize price over lifetime value. Adapting products to a wide variety of fluids, pressures, temperatures, and particulate loads across different end-use sectors requires extensive R&D and field testing. Supply chain disruptions for specialty materials and precision components can delay production and damage customer trust. Finally, educating end users about the long-term benefits of precision nozzles versus cheap replacements remains difficult, slowing the transition to higher-performance products.

Spraying Nozzles Market: Segmentation

The global Spraying Nozzles industry is segmented based on type, application, and region. All the segments have been analyzed based on present and future trends and the market is estimated from 2025 to 2034.

Based on the type, the global market is bifurcated into full cone spray nozzles, hollow cone spray nozzles, fine spray hydraulic nozzles, air atomizing nozzles, automatic spray nozzles, and others. The full cone spray nozzles segment is expected to dominate the market over the forecast period. Full cone spray nozzles are a particular style of spraying device that is frequently employed in a variety of sectors for tasks requiring the even distribution of liquids, gases, or powders in a complete 360-degree circular pattern. These nozzles provide a full cone-shaped spray pattern, making a variety of applications possible. Its adoption is in a wide range of industries including chemical processing, pharmaceuticals, automotive, food & beverages, and others. On the other hand, the hollow cone spray nozzles are expected to hold a significant revenue share over the forecast period. The primary advantages of hollow cone nozzles are that they create the smallest drop sizes, giving the spray a bigger surface area and enabling a speedier transmission of heat, suitable for applications like pasteurization where the target has to be heated or cooled down quickly. Thereby, driving the segment growth.

Based on the application, the global spraying nozzles market is bifurcated into pesticide spraying, household showers, workshop humidification, dust removal, and others. The workshop humidification segment is expected to capture a maximum market share during the forecast period. When producing their final product, the specific industry, such as textiles, employs workshop humidification. The fabric is particularly sensitive to the condition of the air. It is necessary to keep the air clean when taking manufacturing. The yarn typically rips due to the low humidity. The electrical discharge from the treated material is also reduced by humidification. For the humidification process, spraying nozzles are therefore utilized globally. The need for spraying nozzles in the workshop humidification application has grown as a result of the expansion of industrial sectors in recent years.

The Regional, this segment includes the current and forecast demand for North America, Europe, Asia Pacific, Latin America,and the Middle East and Africa.

Spraying Nozzles Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Spraying Nozzles Market |

| Market Size in 2024 | USD 2.84 Billion |

| Market Forecast in 2034 | USD 5.54 Billion |

| Growth Rate | CAGR of 6.4% |

| Number of Pages | 230 |

| Key Companies Covered | BETE, Alfa Laval, Chumpower Machinery, BEX, Düsen-Schlick GmbH, DELAVAN SPRAY TECHNOLOGIES, Exitflex SA, EXAIR, Lechler, Fyrtex, Spraytech Systems (India), Spraying Systems, PNR Nordic AB, Steinen, and others. |

| Segments Covered | By Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2020 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Spraying Nozzles Market: Regional Analysis

Asia-Pacific leads the spraying nozzles market, driven by large-scale agricultural adoption, rapid industrialization, and government support for mechanization. North America remains strong because of advanced manufacturing, stringent environmental and spray-efficiency regulations, and significant demand from automotive and energy sectors. Europe shows steady growth with emphasis on industrial applications, building and process optimization for energy efficiency, and regulatory-driven replacement cycles. Latin America, the Middle East, and Africa are emerging markets with growing uptake in oil and gas, mining, and agriculture, supported by infrastructure investments. Overall, regional demand is shaped by automation and precision-spray technologies, rising focus on water and chemical-use efficiency, and increasing aftermarket and replacement needs.

Spraying Nozzles Market: Competitive Analysis

The report provides a company market share analysis to give a broader overview of the key market players. In addition, the report also covers key strategic developments of the market, including acquisitions & mergers, new product launches, agreements, partnerships, collaborations & joint ventures, research & development, and regional expansion of major participants involved in the spraying nozzles market on a global and regional basis.

The global Spraying Nozzles market is dominated by players like:

- BETE

- Alfa Laval

- Chumpower Machinery

- BEX

- Düsen-Schlick GmbH

- DELAVAN SPRAY TECHNOLOGIES

- Exitflex SA

- EXAIR

- Lechler

- Fyrtex

- Spraytech Systems (India)

- Spraying Systems

- PNR Nordic AB and Steinen

The global Spraying Nozzles market is segmented as follows:

By Type

- Padded

- Non-padded

By Application

- Seamed

- Seamless

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

A device that helps a liquid disperse by creating a spray is known as a spray nozzle or an atomizer. To create a spray, liquid structures like liquid sheets or ligaments must be broken up into droplets, frequently by employing kinetic energy to offset the expense of adding more surface area. Many different types of spray nozzles employ one or more liquid breakup processes. These mechanisms may be categorized into three groups: liquid sheet breakup, jets, and capillary waves. When a spray nozzle is built to have the proper spray properties, it is crucial for many applications.

The global spraying nozzles market is expected to grow due to increasing demand for automation and efficiency across various industries, the growing need for consistent and high-quality surface finishes and precise fluid application, and rising concerns for worker safety and environmental regulations promoting resource optimization.

According to a study, the global spraying nozzles market size was worth around USD 2.84 Billion in 2024 and is expected to reach USD 5.54 Billion by 2034.

The global spraying nozzles market is expected to grow at a CAGR of 6.4% during the forecast period.

North America is expected to dominate the spraying nozzles market over the forecast period.

Leading players in the global spraying nozzles market include BETE, Alfa Laval, Chumpower Machinery, BEX, Düsen-Schlick GmbH, DELAVAN SPRAY TECHNOLOGIES, Exitflex SA, EXAIR, Lechler, Fyrtex, Spraytech Systems (India), Spraying Systems, PNR Nordic AB, Steinen, among others.

The report explores crucial aspects of the spraying nozzles market, including a detailed discussion of existing growth factors and restraints, while also examining future growth opportunities and challenges that impact the market.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed