Global Oil Condition Monitoring Market Size, Share, Growth Analysis Report - Forecast 2034

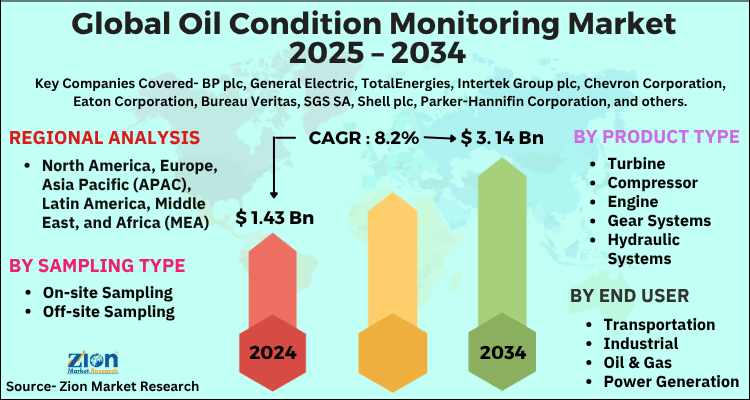

Oil Condition Monitoring Market By Sampling Type (On-site Sampling, Off-site Sampling), By Product Type (Turbine, Compressor, Engine, Gear Systems, Hydraulic Systems), By End user (Transportation, Industrial, Oil & Gas, Power Generation, Mining), and By Region: Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 1.43 Billion | USD 3.14 Billion | 8.2% | 2024 |

Global Oil Condition Monitoring Market: Industry Perspective

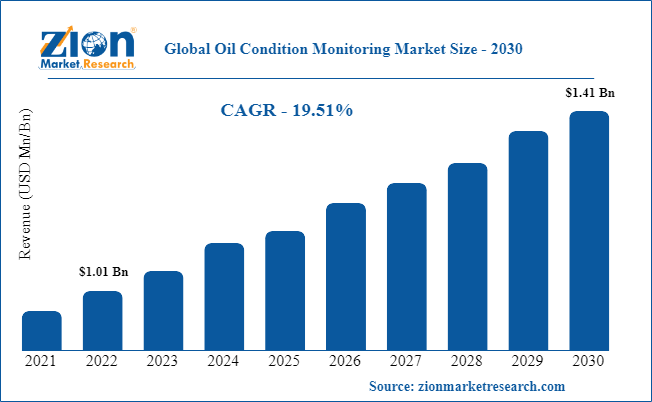

The global oil condition monitoring market size was worth around USD 1.43 Billion in 2024 and is predicted to grow to around USD 3.14 Billion by 2034 with a compound annual growth rate (CAGR) of roughly 8.2% between 2025 and 2034. The report analyzes the global oil condition monitoring market's drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the oil condition monitoring industry.

The report analyzes the global oil condition monitoring market drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the oil condition monitoring industry.

Global Oil Condition Monitoring Market: Overview

Oil condition monitoring (OCM) is the process of monitoring and analyzing the quality of oil used in various end-user verticals like industrial, automotive, aviation, marine, and others. OCM revolves around the analysis of parameters like oxidation, viscosity, acidity, and level of contamination in the oil. These parameters help further understand the condition of the oil and can help companies draw plans for future maintenance needs that may arise due to the regular use of the oil. The information obtained using OCM helps identify any potential failure of equipment which can be put to use for optimizing maintenance schedules and improving equipment reliability along with reduced downtime. It can also be applied to improve the overall lifespan of the equipment. The industry refers to the services and products associated with OCM including software programs, analyzers, sensors, and consulting systems. During the forecast period, the global oil condition monitoring market size is expected to grow at a steady rate.

Global Oil Condition Monitoring Market: Growth Drivers

Growing demand for predictive maintenance to propel market growth

The global oil condition monitoring market is projected to grow owing to the increasing demand for predictive maintenance solutions across industrial applications. It is a maintenance-related strategy employed that leverages the benefits of data analysis tools and other techniques to consistently monitor equipment and predict any maintenance issue that may arise in the coming time. It has several benefits associated with it and hence the demand for such techniques and systems is on the rise in the current machinery and technology-driven world.

For instance, predictive maintenance is known to have a positive impact on increasing equipment uptime since the analytical tools can significantly reduce the downtime of the device by identifying potential errors that may arise in the future giving users enough time to undertake corrective measures. In addition to this, improved safety and equipment reliability along with extended equipment lifespan are other advantages of predictive maintenance.

Restraints:

Technical challenges to restrict the market growth

One of the major growth restraints in the oil condition monitoring industry is in terms of technical challenges that arise while using OCM devices. A small technical glitch in terms of data integration and sensor calibration can impact the overall accuracy of the device causing doubts over its reliability. In addition to this, the lack of standardization across global economies is an added growth limitation for industrial players. It becomes difficult for players to benchmark the performance quality of the system in case of the absence of standard measuring protocols.

Opportunities:

Growing adoption of advanced technologies to provide higher market growth

The oil condition monitoring industry is expected to benefit owing to the rising investments toward the integration of advanced systems like the Internet of Things (IoT) and Artificial Intelligence (AI) along with oil condition monitoring devices and supporting infrastructure. Such integrational measures can allow end-users to monitor the quality of the oil and predict ongoing defaults in the system in real-time along with higher accuracy. Furthermore, cloud-based technology could work in the favor of the players to improve cost efficiency and reporting.

Challenges:

Integration with already existing systems to challenge market growth

It may be difficult for new consumers to integrate newer OCM systems with already existing or legacy protocols in the business. This is especially applicable to incidents where older systems are outdated or lack compatibility with modern technologies. In addition to this, the general reluctance to change in end-user verticals is a crucial challenge for the industry players to tackle. Concerns like the unavailability of skilled professionals cost curiosity, and doubts over reliability are aspects of reluctance in potential consumers.

Key Insights

- As per the analysis shared by our research analyst, the global oil condition monitoring market is estimated to grow annually at a CAGR of around 8.2% over the forecast period (2025-2034).

- Regarding revenue, the global oil condition monitoring market size was valued at around USD 1.43 Billion in 2024 and is projected to reach USD 3.14 Billion by 2034.

- The oil condition monitoring market is projected to grow at a significant rate due to rising demand for predictive maintenance in industries, increasing adoption of IoT-enabled sensors, stringent environmental regulations, and growth in transportation and energy sectors.

- Based on Sampling Type, the On-site Sampling segment is expected to lead the global market.

- On the basis of Product Type, the Turbine segment is growing at a high rate and will continue to dominate the global market.

- Based on the End user, the Transportation segment is projected to swipe the largest market share.

- Based on region, North America is predicted to dominate the global market during the forecast period.

Global Oil Condition Monitoring Market Report Scope:

| Report Attributes | Report Details |

|---|---|

| Report Name | Oil Condition Monitoring Market |

| Market Size in 2024 | USD 1.43 Billion |

| Market Forecast in 2034 | USD 3.14 Billion |

| Growth Rate | CAGR of 8.2% |

| Number of Pages | 210 |

| Key Companies Covered | BP plc, General Electric, TotalEnergies, Intertek Group plc, Chevron Corporation, Eaton Corporation, Bureau Veritas, SGS SA, Shell plc, Parker-Hannifin Corporation, and others. |

| Segments Covered | By Sampling Type, By Product Type, By End user, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2020 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Global Oil Condition Monitoring Market: Segmentation

The global oil conditioning monitoring market is segmented based on product type, sampling type, vertical, and region. All the segments have been analyzed based on present and future trends and the market is estimated from 2025 to 2034.

Based on product type, the global market segments are engine, turbine, hydraulic system, compressor, and others. In 2024, the industry registered the highest growth in the engine segment since it is one of the most widely used parts in the automotive segment, a fast-growing end-user vertical. Engines are also critical in other sectors like power generation, aviation, and marine. Since the product is constantly subjected to changing operating conditions like high pressure, temperature, and speed, engines are more susceptible to wear and tear. OCM in engines can effectively analyze the quality of the engine oil and send out an early warning for the user to undertake precautionary and corrective steps. As per the US Department of Energy, the OCM program in diesel-powered engines can assist in the reduction of engine maintenance costs by 25%.

Based on sampling type, the oil condition monitoring industry segments are off-site and on-site.

Based on vertical, the global market divisions are oil & gas, power generation, industrial, mining, and transportation. The largest revenue contributor in the industry is the oil & gas segment where the technology is used for large-scale applications like drilling, oil exploration, and refining activities. In power generation, the OCM technology is applied for monitoring and analyzing the conditions of turbines, generators, and transformers for their efficient and reliable performance. As per the International Energy Agency (IEA), the oil and gas industry is responsible for consuming approximately 5% of global oil production for drilling operations alone.

The Regional, this segment includes the current and forecast demand for North America, Europe, Asia Pacific, Latin America,and the Middle East and Africa.

Recent Developments:

- In August 2024, Shell, a US-based oil and gas company, announced the launch of a new service dedicated to oil condition monitoring and equipment health. The move came in as a response to collaboration between Shell and Baker Hughes and the product is called VitalyX, a highly advanced and intelligent analytics-based oil condition monitoring, and machinery health service, especially for the marine segment

- In June 2024, Parker Hannifin, a leading provider of motion and control technologies, announced the launch of DIGI Plus, which is regarded as an innovative OCM technology. It offers on-board and on-site monitoring of oil condition

- In June 2024, Rexnord Process & Motion Control (PMC) announced a new addition to its existing line of Smart Condition Monitoring Systems called 1030. The OCM system can monitor oil quality, vibration, and temperature on most of the large gear drives

Global Oil Condition Monitoring Market: Regional Analysis

The Oil Condition Monitoring Market shows strong regional dynamics, with North America leading due to the widespread presence of key industries such as oil and gas, power generation, and transportation, coupled with a high emphasis on predictive maintenance practices. Europe follows closely, driven by stringent regulations on machinery efficiency and environmental standards, particularly in industries like automotive and manufacturing. In Asia-Pacific, rapid industrialization, expanding automotive production, and growing energy needs in countries like China and India are fueling demand for oil condition monitoring solutions. Meanwhile, the Middle East and Africa are witnessing increasing adoption, spurred by the focus on extending the operational life of critical assets in oil and gas operations, while Latin America is gradually gaining momentum as industries invest more in equipment reliability and cost optimization strategies.

Global Oil Condition Monitoring Market: Competitive Analysis

The report provides a company market share analysis to give a broader overview of the key market players. In addition, the report also covers key strategic developments of the market, including acquisitions & mergers, new product launches, agreements, partnerships, collaborations & joint ventures, research & development, and regional expansion of major participants involved in the oil condition monitoring market on a global and regional basis.

The global oil condition monitoring market is dominated by players like:

- BP plc

- General Electric

- TotalEnergies

- Intertek Group plc

- Chevron Corporation

- Eaton Corporation

- Bureau Veritas

- SGS SA

- Shell plc

- Parker-Hannifin Corporation

Global Oil Condition Monitoring Market: Segmentation Analysis

The global oil condition monitoring market is segmented as follows;

By Sampling Type

- On-site Sampling

- Off-site Sampling

By Product Type

- Turbine

- Compressor

- Engine

- Gear Systems

- Hydraulic Systems

By End user

- Transportation

- Industrial

- Oil & Gas

- Power Generation

- Mining

Global Oil Condition Monitoring Market: Regional Segment Analysis

- North America

- The U.S.

- Canada

- Mexico

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Australia

- South Korea

- Rest of Asia Pacific

- The Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- Kuwait

- South Africa

- Rest of the Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

Table Of Content

Methodology

FrequentlyAsked Questions

Oil condition monitoring (OCM) is the process of monitoring and analyzing the quality of oil used in various end-user verticals like industrial, automotive, aviation, marine, and others. OCM revolves around the analysis of parameters like oxidation, viscosity, acidity, and level of contamination in the oil. These parameters help further understand the condition of the oil and can help companies draw plans for future maintenance needs that may arise due to the regular use of the oil. The information obtained using OCM helps identify any potential failure of equipment which can be put to use for optimizing maintenance schedules and improving equipment reliability along with reduced downtime.

The global oil condition monitoring market is expected to grow due to increasing demand for predictive maintenance to reduce operational downtime and maintenance costs, the growing adoption of advanced technologies like IoT and AI for real-time monitoring and data analysis, and stringent regulations across various industrie.

According to a study, the global oil condition monitoring market size was worth around USD 1.43 Billion in 2024 and is expected to reach USD 3.14 Billion by 2034.

The global oil condition monitoring market is expected to grow at a CAGR of 8.2% during the forecast period.

North America is expected to dominate the oil condition monitoring market over the forecast period.

Leading players in the global oil condition monitoring market include BP plc, General Electric, TotalEnergies, Intertek Group plc, Chevron Corporation, Eaton Corporation, Bureau Veritas, SGS SA, Shell plc, Parker-Hannifin Corporation, among others.

The report explores crucial aspects of the oil condition monitoring market, including a detailed discussion of existing growth factors and restraints, while also examining future growth opportunities and challenges that impact the market.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed