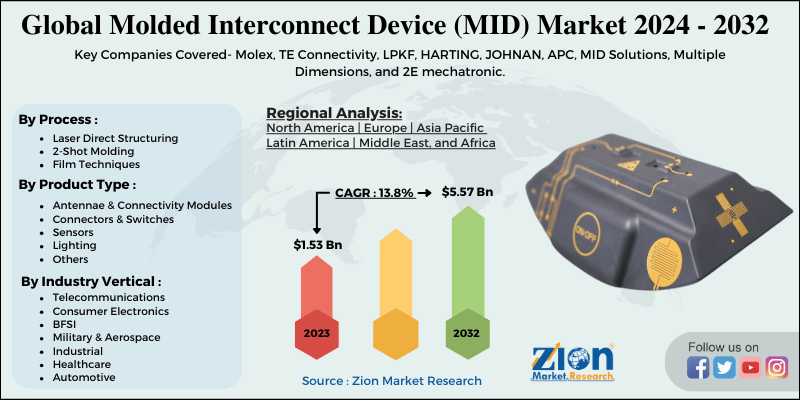

Molded Interconnect Device (MID) Market Size, Share, Growth, Forecast 2032

Molded Interconnect Device (MID) Market By Process (Laser Direct Structuring, 2-Shot Molding, Film Techniques) by Product Type (Antennae & Connectivity Modules, Connectors & Switches, Sensors, Lighting, Others) by Industry Vertical (Telecommunications, Consumer Electronics, BFSI, Military & Aerospace, Industrial, Healthcare, Automotive, Others): Global Industry Perspective, Comprehensive Analysis and Forecast, 2024 - 2032-

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 1.53 Billion | USD 5.57 Billion | 13.8% | 2023 |

Molded Interconnect Device (MID) Market Insights

According to Zion Market Research, the global Molded Interconnect Device (MID) Market was worth USD 1.53 Billion in 2023. The market is forecast to reach USD 5.57 Billion by 2032, growing at a compound annual growth rate (CAGR) of 13.8% during the forecast period 2024-2032. The report offers a comprehensive analysis of the market, highlighting the factors that will determine growth, potential challenges, and opportunities that could emerge in the Molded Interconnect Device (MID) Market industry over the next decade.

Global Molded Interconnect Device (MID) Market: Overview

Molded interconnect devices (MIDs) are injection-molded thermoplastic substrates with conductive circuit patterns that combine mechanical and electrical functions. They are generally 3-dimensional, and a number of techniques can be used to apply the components and conductors. Although the technology has advanced significantly in recent years, especially with the advancement of light-temperature resins and the use of rapid prototyping techniques to produce pre-production examples, however, traditional planar printed circuit board technology will continue to meet the demands for multilayers, large component densities, and plated-through holes.

With the introduction of features such as soldering pads and plated through-hole vias, it has become increasingly popular for MID solutions to include other components such as antennas and sensor interfaces. Consumer electronics, telecommunications, automobile, and medical are key markets for MID technology. MIDs are widely used as integrated antennas in cellphones and other mobile devices such as laptops and netbooks.

Global Molded Interconnect Device (MID) Market: Growth Factors

Today's portable electronic devices with various functions in a small package are in high demand. To satisfy the miniaturisation requirement, mechanical and electrical systems must be integrated into a single product, which can be easily accomplished using MID. It aids in the integration of circuitry, connectors, housing, and cables into a single component. In consumer electronics, there is a growing need for more electronic circuits to be integrated into smaller spaces. For example, a smartphone needs an antenna; rather than engineering a stand-alone antenna.

The two-shot molding segment dominates the industry, owing to its ability to improve the performance and aesthetics of rubber and plastic molding products. Moreover, the process needs only one machine cycle, which reduces manufacturing costs and deliver more products per process. Since the process ensures a strong connection between materials, it is widely used in automotive interior components and medical devices among others.

The growing demand for designing medical-grade components, tools, and equipment would increase the demand for two-shot molding processes, providing an advantage for the growth of the molded interconnect devices industry. In healthcare applications, the process can handle requirements such as medical cleanliness and complex designs.

To achieve a competitive advantage over other players, companies are implementing innovation and growth strategies in the molding processes. For instance, in January 2019, GW Plastics announced plans to expand its multi-shot molding capabilities in order to increase automation and meet the needs of healthcare OEMs.

Global Molded Interconnect Device (MID) Market: Segmentation

Injection molding, laser activation, and metallization are the three fundamental stages in Laser Direct Structure (LDS). LDS requires only a single thermoplastic material to create a MID, making the molding phase a one-shot operation. The fact that there is only one part, implies that the circuitry is produced on the plastic itself, which is one of the distinctive characteristics of LDS. Laser activation is the second stage in the LDS process. At this stage, a physiochemical reaction takes place, which laser etched the wiring pattern onto the part and sets it for metallization. To allow LDS to function properly, the part molded in phase one must be made of an LDS grade material. These products, which are available from most major plastics suppliers, are doped versions of standard plastics such as acrylonitrile-butadiene-styrene (ABS) or nylon.

Automotive applications held a significant market share in 2020 and is projected to expand at a rapid pace in the near future. The spike is due to the increasing use of molded interconnect devices in a variety of automotive applications such as steering wheel hubs, position sensors, lighting and brake sensors.

In automotive applications, these devices are used to lower the number of wirings and integrate the requisite circuitry, including housings and connectors, into a single piece. Because of these features, molded interconnect devices will be in high demand from automotive manufacturers looking to create compact devices at a lower cost.

The industry would benefit from increasing customer demand for more electronic features in vehicles. Major players in the automotive industry are launching a slew of new safety and entertainment features in order to provide comfort and meet market demand. According to the OICA (International Organization of Motor Vehicle Manufacturers), automobile production in 2018 increased by 5.2% in Brazil, 8.0% in India,13.9% and 67.7% in Russia and Portugal respectively.

Molded Interconnect Device (MID) Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Molded Interconnect Device (MID) Market |

| Market Size in 2023 | USD 1.53 Billion |

| Market Forecast in 2032 | USD 5.57 Billion |

| Growth Rate | CAGR of 13.8% |

| Number of Pages | 110 |

| Key Companies Covered | Molex, TE Connectivity, LPKF, HARTING, JOHNAN, APC, MID Solutions, Multiple Dimensions, and 2E mechatronic |

| Segments Covered | By Process, By Product Type, By Industry Vertical and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Global Molded Interconnect Device (MID) Market: Regional Analysis

By Geography, the MID market is segmented into North America, Europe, Latin America, Asia Pacific, and Middle East and Africa.

The Asia Pacific molded interconnect devices market will develop at a rapid pace in the near future. This is due to the increasing consumer electronics industry in India and China, which has an ample supply of raw materials and a large pool of cheap labour.

This has encouraged many leaders in the consumer electronics industry to increase their presence in the region. Technology companies are focusing on providing more secure and lightweight portable electronic devices, generating massive business opportunities for market participants. In addition, many government measures to broaden the manufacturing sector would benefit the industry.

Global Molded Interconnect Device (MID) Market: Competitive Players

The major players in the global MID market include

- Molex

- TE Connectivity

- LPKF

- HARTING

- JOHNAN

- APC

- MID Solutions

- Multiple Dimensions

- 2E mechatronic

The report segment of global MID market are as follows:

Global Molded Interconnect Device (MID) Market: Process Segment Analysis

- Laser Direct Structuring

- 2-Shot Molding

- Film Techniques

Global Molded Interconnect Device (MID) Market: Product Type Segment Analysis

- Antennae & Connectivity Modules

- Connectors & Switches

- Sensors

- Lighting

- Others

Global Molded Interconnect Device (MID) Market: Industry Vertical Segment Analysis

- Telecommunications

- Consumer Electronics

- BFSI

- Military & Aerospace

- Industrial

- Healthcare

- Automotive

- Others

Global Molded Interconnect Device (MID) Market: Regional Segment Analysis

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

A molded interconnect device (MID) is a three-dimensional, injection-molded object combining mechanical and electronic capabilities into one single device. By directly integrating electrical circuits straight onto a plastic substrate, MIDs enable the construction of intricate electronic circuits into molded plastic products. This special ability helps MIDs to fulfill both structural and electronic needs, hence lowering the demand for several parts and connectors in electronic assemblies.

Where space-saving and lightweight components are vital for vehicle design and efficiency, the automotive sector uses MIDs in sensors, lights, and infotainment systems progressively.

According to Zion Market Research, the global Molded Interconnect Device (MID) Market was worth USD 1.53 Billion in 2023. The market is forecast to reach USD 5.57 Billion by 2032.

According to Zion Market Research, the global Molded Interconnect Device (MID) Market a compound annual growth rate (CAGR) of 13.8% during the forecast period 2024-2032.

By Geography, the MID market is segmented into North America, Europe, Latin America, Asia Pacific, and Middle East and Africa.

The major players in the global MID market include Molex, TE Connectivity, LPKF, HARTING, JOHNAN, APC, MID Solutions, Multiple Dimensions, and 2E mechatronic among others.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed

-market-size.png)