Global Insoluble Sulfur Market Size, Share, Growth Analysis Report - Forecast 2034

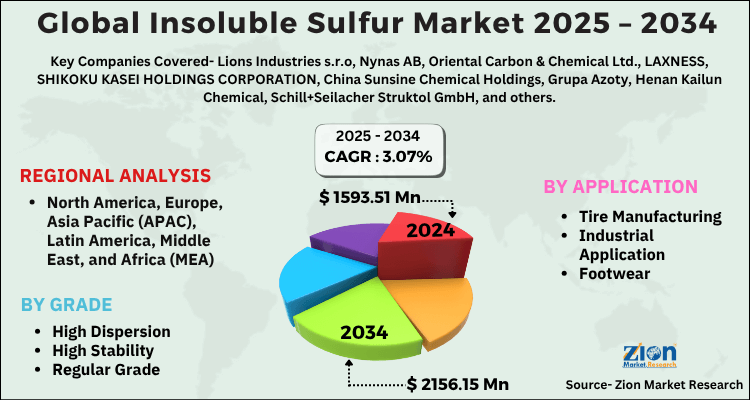

Insoluble Sulfur Market By Grade (High Dispersion, High Stability, Regular), By Application (Tire Manufacturing, Industrials, Footwear, Others), and By Region: Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 1593.51 Million | USD 2156.15 Million | 3.07% | 2024 |

Global Insoluble Sulfur Market: Industry Perspective

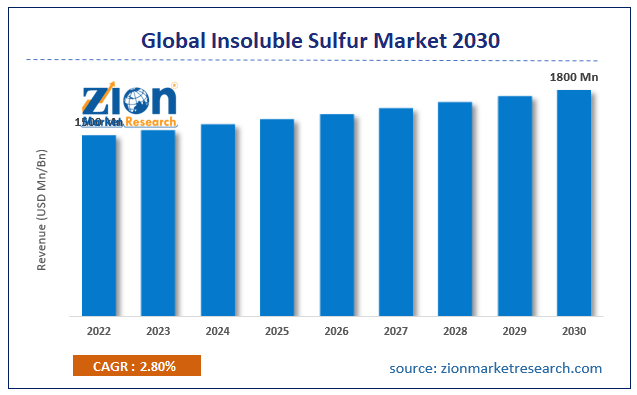

The global insoluble sulfur market size was worth around USD 1593.51 Million in 2024 and is predicted to grow to around USD 2156.15 Million by 2034 with a compound annual growth rate (CAGR) of roughly 3.07% between 2025 and 2034. The report analyzes the global insoluble sulfur market's drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the insoluble sulfur industry.

The report analyzes the global insoluble sulfur market drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the insoluble sulfur industry.

Global Insoluble Sulfur Market: Overview

Insoluble sulfur refers to a form of elemental sulfur that has limited solubility in various organic solvents and rubber matrices. Sulfur itself is a yellow, brittle, and solid chemical element found in nature. It is widely used in the rubber industry as a vulcanizing agent to enhance the properties and durability of rubber materials. Traditional forms of sulfur used in rubber compounding are soluble in organic solvents like carbon disulfide. However, these soluble forms tend to migrate within the rubber matrix, leading to uneven distribution and potential performance issues. To overcome this problem, insoluble sulfur was developed. Insoluble sulfur is produced through a controlled chemical reaction that results in sulfur particles with a polymer coating. This coating makes the sulfur insoluble in common solvents and prevents its migration within rubber compounds. The insoluble nature of this form of sulfur ensures a more uniform distribution within the rubber matrix during compounding and vulcanization, leading to improved product quality and performance.

The use of insoluble sulfur offers several advantages in rubber manufacturing, such as better dispersion, reduced bloom (surface deposition), increased heat resistance, improved aging properties, and enhanced rubber cross-linking. These characteristics contribute to the overall strength, durability, and stability of rubber products, especially those exposed to challenging conditions, such as high temperatures and oxidative environments. Insoluble sulfur is commonly employed in the production of various rubber goods, including tires, conveyor belts, seals, hoses, and other molded or extruded rubber components. Its unique properties make it an essential ingredient in rubber compounding processes, ensuring the reliable performance and longevity of rubber-based products.

Global Insoluble Sulfur Market: Growth Drivers

Growing demand for rubber products drives the market growth

The growing demand for rubber products, particularly in the automotive industry, is a major driver for the insoluble sulfur market. Insoluble sulfur is extensively used as a vulcanizing agent in the production of tires, where it improves the mechanical properties and durability of the rubber. With the expanding automotive industry and the rising demand for high-performance tires, the demand for insoluble sulfur is expected to grow. For instance, according to information from the Ministry of Industry and Information Technology, approximately 26 million vehicles, including 21.48 million passenger cars, were sold in 2021, an increase of 7.1% from the previous year. Moreover, according to the Bureau of Transportation Statistics, the total production of vehicles in the US (including passenger cars and commercial vehicles) understood around 9.1 million units as compared to 8.8 million units in 2020, an increase of 4.5% from the previous year. Therefore, the aforementioned fact supports the market expansion over the forecast period.

Restraints:

Dependency on the rubber industry might be hampering the market growth

The insoluble sulfur industry is closely tied to the rubber industry. Any fluctuations or downturns in the rubber industry can have a direct impact on the demand for insoluble sulfur. Economic uncertainties, changes in consumer preferences, or shifts in automotive and tire production can affect the overall demand for rubber products and consequently impact the market.

Opportunities:

Technological advancements in rubber compounding offer a significant opportunity

The development of advanced rubber compounding technologies has driven the demand for insoluble sulfur. Modern compounding techniques, such as masterbatch systems and automated mixing processes, require insoluble sulfur for optimal dispersion and uniform distribution within rubber compounds. These technological advancements have increased the efficiency and effectiveness of rubber compounding, further driving the demand for insoluble sulfur. For instance, as part of a significant, creative, and strategic transformation journey that would improve and transform its business in the upcoming years, Nynas announced and planned enhancements.

Challenges:

Environmental regulation poses a major challenge to the market expansion

Environmental regulations and sustainability initiatives can impact the market for insoluble sulfur. The rubber industry is increasingly focused on reducing environmental impact and developing sustainable solutions. As a result, there may be a shift towards alternative additives and compounding technologies that have a lower environmental footprint. Compliance with environmental regulations and the need for eco-friendly solutions may pose challenges to the growth of the insoluble sulfur market.

Key Insights

- As per the analysis shared by our research analyst, the global insoluble sulfur market is estimated to grow annually at a CAGR of around 3.07% over the forecast period (2025-2034).

- Regarding revenue, the global insoluble sulfur market size was valued at around USD 1593.51 Million in 2024 and is projected to reach USD 2156.15 Million by 2034.

- The insoluble sulfur market is projected to grow at a significant rate due to growing from the tire manufacturing industry due to the increasing number of on-road vehicles and the rising need for high-performance and durable tires.

- Based on Grade, the High Dispersion segment is expected to lead the global market.

- On the basis of Application, the Tire Manufacturing segment is growing at a high rate and will continue to dominate the global market.

- Based on region, Asia-Pacific is predicted to dominate the global market during the forecast period.

Global Insoluble Sulfur Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Insoluble Sulfur Market |

| Market Size in 2024 | USD 1593.51 Million |

| Market Forecast in 2034 | USD 2156.15 Million |

| Growth Rate | CAGR of 3.07% |

| Number of Pages | 219 |

| Key Companies Covered | Lions Industries s.r.o, Nynas AB, Oriental Carbon & Chemical Ltd., LAXNESS, SHIKOKU KASEI HOLDINGS CORPORATION, China Sunsine Chemical Holdings, Grupa Azoty, Henan Kailun Chemical, Schill+Seilacher Struktol GmbH, and others. |

| Segments Covered | By Grade, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2020 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Global Insoluble Sulfur Market: Segmentation

The global insoluble sulfur industry is segmented based on grade, application, and region. All the segments have been analyzed based on present and future trends and the market is estimated from 2025 to 2034.

Based on the grade, the global market is bifurcated into high dispersion, high stability, and regular grade. The regular grade segment is expected to capture the largest market share over the forecast period. This is due to the product's widespread use across all industries that make rubber compounds. Additionally, the standard grade product—which is often one without any additional mixtures—is regarded in the industry as the most fundamental type of insoluble sulfur. All significant insoluble sulfur industry players make the regular form, which is extensively utilized as a vulcanizing agent. Despite the material being deemed non-hazardous by EC standards, it is nonetheless urged that anybody handling it at work take some basic safety procedures. On the other hand, the high dispersion segment is expected to grow significantly during the forecast period because the material is widely used in the manufacture of tires due to its important properties, such as great dispersibility and strong thermal stability. It typically has 20% or less of oil-treated, insoluble sulfur in powder form. In comparison to the other classes, it often has lower insoluble sulfur concentrations. It is typically made of polymers, including SBR, EPDM, and different dispersion agents. Thereby, driving the segment growth during the forecast period.

Based on the application, the global insoluble sulfur industry is divided into tire manufacturing, industrial application, footwear, and others. The tire manufacturing segment is expected to dominate the market during the forecast period. This is related to the substantial product demand coming from the globally expanding tire manufacturing industry. Because insoluble sulfur is a crucial feedstock for creating high-quality performance goods, tire manufacturers are heavily dependent on these formulators. Many businesses, like Eastman Chemical Company, Oriental Carbon & Chemicals Ltd., and others, are concentrating on creating high-quality products that are simple for tire manufacturers to utilize, which might ultimately result in a reduction in manufacturing time and give high-performance goods. Increased productivity and shorter deadlines eventually result in a drop in the firms' cost-bearing obligations, and are thus seen as essential to the use of the product. Thereby, driving the segment growth.

The Regional, this segment includes the current and forecast demand for North America, Europe, Asia Pacific, Latin America,and the Middle East and Africa.

Global Insoluble Sulfur Market: Regional Analysis

The insoluble sulfur market exhibits diverse regional dynamics, with Asia-Pacific dominating due to its robust tire manufacturing sector and rising automotive production, especially in countries like China and India. North America and Europe also hold significant shares, driven by steady demand in automotive and industrial rubber applications, alongside stringent environmental regulations favoring safer vulcanization agents like insoluble sulfur. Meanwhile, regions such as Latin America and the Middle East & Africa are witnessing gradual growth, fueled by expanding automotive industries and infrastructure projects that increase the consumption of rubber products. Overall, regional growth varies in line with industrialization levels, automotive sector trends, and regulatory landscapes influencing rubber compounding practices.

Global Insoluble Sulfur Market: Competitive Analysis

The report provides a company market share analysis to give a broader overview of the key market players. In addition, the report also covers key strategic developments of the market, including acquisitions & mergers, new product launches, agreements, partnerships, collaborations & joint ventures, research & development, and regional expansion of major participants involved in the insoluble sulfur market on a global and regional basis.

The global insoluble sulfur market is dominated by players like:

- Lions Industries s.r.o

- Nynas AB

- Oriental Carbon & Chemical Ltd.

- LAXNESS

- SHIKOKU KASEI HOLDINGS CORPORATION

- China Sunsine Chemical Holdings

- Grupa Azoty

- Henan Kailun Chemical

- Schill+Seilacher Struktol GmbH

Global Insoluble Sulfur Market: Segmentation Analysis

The global insoluble sulfur market is segmented as follows;

By Grade

- High Dispersion

- High Stability

- Regular Grade

By Application

- Tire Manufacturing

- Industrial Application

- Footwear

- Others

Global Insoluble Sulfur Market: Regional Segment Analysis

- North America

- The U.S.

- Canada

- Mexico

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Australia

- South Korea

- Rest of Asia Pacific

- The Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- Kuwait

- South Africa

- Rest of the Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

Table Of Content

Methodology

FrequentlyAsked Questions

Insoluble sulfur refers to a form of elemental sulfur that has limited solubility in various organic solvents and rubber matrices. Sulfur itself is a yellow, brittle, and solid chemical element found in nature. It is widely used in the rubber industry as a vulcanizing agent to enhance the properties and durability of rubber materials. Traditional forms of sulfur used in rubber compounding are soluble in organic solvents like carbon disulfide. However, these soluble forms tend to migrate within the rubber matrix, leading to uneven distribution and potential performance issues. To overcome this problem, insoluble sulfur was developed. Insoluble sulfur is produced through a controlled chemical reaction that results in sulfur particles with a polymer coating. This coating makes the sulfur insoluble in common solvents and prevents its migration within rubber compounds. The insoluble nature of this form of sulfur ensures a more uniform distribution within the rubber matrix during compounding and vulcanization, leading to improved product quality and performance.

The global insoluble sulfur market is expected to grow due to rising demand in tire and rubber industries, increasing automotive production, stringent quality standards for high-performance materials, and growth in industrial rubber applications.

According to a study, the global insoluble sulfur market size was worth around USD 1593.51 Million in 2024 and is expected to reach USD 2156.15 Million by 2034.

Asia-Pacific is expected to dominate the insoluble sulfur market over the forecast period.

Asia-Pacific is expected to dominate the insoluble sulfur market over the forecast period.

Leading players in the global insoluble sulfur market include Lions Industries s.r.o, Nynas AB, Oriental Carbon & Chemical Ltd., LAXNESS, SHIKOKU KASEI HOLDINGS CORPORATION, China Sunsine Chemical Holdings, Grupa Azoty, Henan Kailun Chemical, Schill+Seilacher Struktol GmbH, among others.

The report explores crucial aspects of the insoluble sulfur market, including a detailed discussion of existing growth factors and restraints, while also examining future growth opportunities and challenges that impact the market.

RelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed