Flow Chemistry Market Size, Share, Analysis, Growth, Forecasts 2032

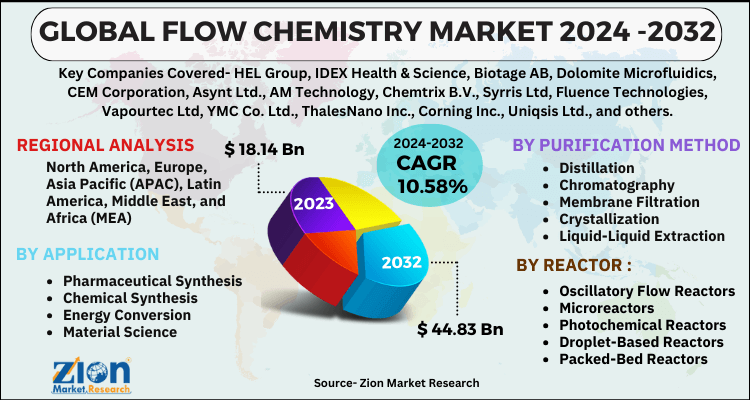

Flow Chemistry Market By Application (Pharmaceutical Synthesis, Chemical Synthesis, Energy Conversion, Material Science, and Others), By Purification Method (Distillation, Chromatography, Membrane Filtration, Crystallization, Liquid-Liquid Extraction, and Others), By Reactor (Oscillatory Flow Reactors, Microreactors, Photochemical Reactors, Droplet-Based Reactors, Packed-Bed Reactors, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2024 - 2032

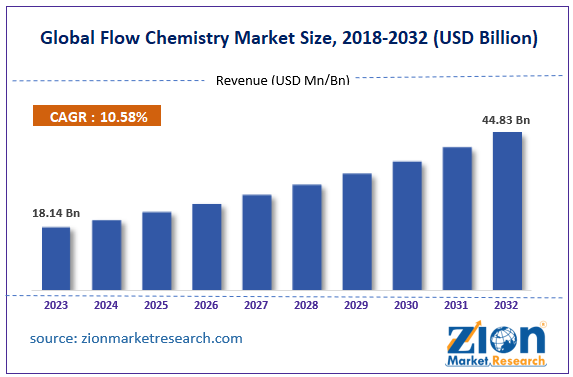

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 18.14 Billion | USD 44.83 Billion | 10.58% | 2023 |

Flow Chemistry Industry Perspective:

The global flow chemistry market size was worth around USD 18.14 billion in 2023 and is predicted to grow to around USD 44.83 billion by 2032, with a compound annual growth rate (CAGR) of roughly 10.58% between 2024 and 2032.

Flow Chemistry Market: Overview

Flow chemistry is a type of chemical process that involves the use of tubing or channel systems to facilitate a chemical reaction. Reaction parameters are better controlled in flow chemistry since the reaction is carried out in a continuous stream as opposed to flask-based reactions.

Thus, researchers can enhance reactivity, and in some cases, it also promotes new reactions. Flow chemistry is a relatively new technology, but has gained extreme growth momentum in the last few years. In the scientific world, flow chemistry is also known as plug flow chemistry and continuous flow.

Some of the most significant breakthroughs achieved through flow chemistry are the production of Artemisinin and Tamoxifen. The former is used for the treatment of malaria while the latter has been extensively applied in the treatment process of breast cancer. The process involves pumping reactors into a mixing device. Until the reaction is complete, the flow is continued using a temperature-controlled reactor.

In some cases, the reactors may also be exposed to photon or electron flux to promote photochemical or electrochemical reactions. The demand for flow chemistry has been growing across industries such as pharmaceutical, research, and others.

However, the high cost of initial infrastructure development and the limited availability of skilled professionals may impact the overall revenue.

Key Insights:

- As per the analysis shared by our research analyst, the global flow chemistry market is estimated to grow annually at a CAGR of around 10.58% over the forecast period (2024-2032)

- In terms of revenue, the global flow chemistry market size was valued at around USD 18.14 billion in 2023 and is projected to reach USD 44.83 billion by 2032.

- The flow chemistry market is projected to grow at a significant rate due to the increasing use in the drug discovery and pharmaceutical industries.

- Based on application, the chemical synthesis segment is growing at a high rate and will continue to dominate the global market as per industry projections.

- Based on reactors, the microreactors segment is anticipated to command the largest market share.

- Based on region, Asia-Pacific is projected to dominate the global market during the forecast period.

Flow Chemistry Market: Growth Drivers

Increasing use in the drug discovery and pharmaceutical industries to promote market growth rate

The global flow chemistry market is projected to witness high growth due to the increasing use of the technology in the pharmaceutical and drug discovery industries.

According to market research, flow chemistry has been integral to the novel transformative approach adopted by drug developers. Flow chemistry is considered an excellent solution to the complexities associated with multi-step drug manufacturing. The main advantage of flow chemistry involves the creation of superior synthetic systems.

For instance, the new chemical reaction-enabling method involves efficient mixing and higher accuracy over control of temperature, pressure, and reaction time.

Furthermore, flow chemistry also facilitates improved process safety due to low reactant hold-up. The demand for flow chemistry in drug development and manufacturing is especially significant in the synthesis of Active Pharmaceutical Ingredients (APIs).

According to the official definition, APIs are the most essential ingredients in a medicine to deliver the expected or desired result.

Furthermore, flow chemistry drug manufacturing is also essential to meet the end demand from the consumers, especially during the production of personalized medicines. Continuous flow is crucial to enable the on-demand manufacturing technique adopted by drug makers worldwide.

Increasing use of green chemical processes to generate higher revenue in the industry

The global flow chemistry market is projected to be further impacted by the growing use of the novel process in green chemical processes.

According to the American Chemical Society, the concept of green chemistry is crucial to sustainable growth in the future. The main principles of green chemistry focus on conserving energy, reducing waste, and discovering alternatives to hazardous chemicals or materials.

Flow chemistry promotes the optimal use of resources, including reaction ingredients and power sources. Leading economies such as the US and European nations are some of the largest contributors to green chemistry.

In March 2024, Beyond Benign and Dow announced the launch of a new partnership focusing on advancing education on green chemistry.

Flow Chemistry Market: Restraints

High initial cost of investment and lack of skilled professionals limit the industry’s expansion trend

The global industry for flow chemistry is projected to be restricted due to the high cost of initial investment. The technique requires the use of specialized equipment including a carefully crafted reactor along with mixers, pumps, heat exchangers, and other control systems.

In addition to this, the technique is heavily dependent on automated solutions which require the implementation of advanced software systems.

The overall expenses associated with the employment of skilled professionals further lead to higher expenses. The limited availability of market experts increases the cost of hiring.

Flow Chemistry Market: Opportunities

Increasing investments in greater commercialization of flow chemistry to generate growth opportunities

The global flow chemistry market is projected to generate growth opportunities due to the increasing investments from major companies in novel technology.

In August 2024, Flamma and Axplora, two dominant giants in the Contract Development and Manufacturing Organization (CDMO) industry, announced considerable investments in the flow chemistry segment. Explora announced that it had completed the installation of a new current Good Manufacturing Practice (cGMP) pilot facility in Germany. On the other hand, Flamma recorded that it will invest nearly USD 2 million in flow chemistry.

The company is expected to begin the investment process by constructing a new set of equipment from Microinnova in Italy. The facility built by Axplora is equipped with cutting-edge solutions that can operate at temperatures ranging from -50°C to 200°C and handle a pressure of 40 bar.

In November 2021, in the backdrop of growing demand for niche chemistry for the production of novel APIs, Angelini Fine Chemicals announced investments in flow chemistry and micro reaction technology for innovation and cGMP of small molecule Highly Potent Active Pharmaceutical Ingredients (HPAPIs), Advanced Intermediates (Adv. IMs.), and APIs.

Flow Chemistry Market: Challenges

Scaling related complaints to challenge the market expansion trends in the future

The global flow chemistry industry is expected to be challenged by the issues related to production scaling. For instance, market research suggests that the lack of availability of a sufficient volume of authorized or validated production units if the market players plan to enhance the production rate.

Flow Chemistry Market: Segmentation

The global flow chemistry market is segmented based on application, purification method, reactor, and region.

Based on the application, the global market segments are pharmaceutical synthesis, chemical synthesis, energy conversion, material science, and others.

In 2023, the highest growth was listed in the chemical synthesis segment. It dominated over 20% of the total market share. It deals with the production of essential chemical compounds using a controlled yet continuous flow. The several advantages offered by flow chemistry in conducting specialized reactions will promote exceptional growth in the industry.

Based on purification methods, the global flow chemistry industry is divided into distillation, chromatography, membrane filtration, crystallization, liquid-liquid extraction, and others.

Based on the reactors, the global market segments are oscillatory flow reactors, microreactors, photochemical reactors, droplet-based reactors, packed-bed reactors, and others.

In 2023, the microreactors segment was the leading revenue generator. The exceptional versatility of microreactors, along with scalability features, helps the segment thrive. Microreactors have shown excellent compatibility with a large range of flow chemistry solutions, promoting their adoption rate. The average cost of lab-scale microreactors is around USD 2000 to USD 15000.

Flow Chemistry Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Flow Chemistry Market |

| Market Size in 2023 | USD 18.14 Billion |

| Market Forecast in 2032 | USD 44.83 Billion |

| Growth Rate | CAGR of 10.58% |

| Number of Pages | 214 |

| Key Companies Covered | HEL Group, IDEX Health & Science, Biotage AB, Dolomite Microfluidics, CEM Corporation, Asynt Ltd., AM Technology, Chemtrix B.V., Syrris Ltd, Fluence Technologies, Vapourtec Ltd, YMC Co. Ltd., ThalesNano Inc., Corning Inc., Uniqsis Ltd., and others. |

| Segments Covered | By Application, By Purification Method, By Reactor, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Flow Chemistry Market: Regional Analysis

Asia-Pacific leads the market growth with the highest revenue rate

The global flow chemistry market is led by Asia-Pacific. In 2023, the region dominated nearly 45.01% of the global revenue, with China, India, South Korea, and Japan acting as the major revenue generators.

The presence of a massive and highly influential chemicals & materials industry in China is a leading contributor to the regional revenue. China has been investing heavily in specialized chemicals and materials production thus subsequently driving the demand for flow chemistry across the region.

In July 2023, reports emerged suggesting that Chinese academic institutions were some of the largest regional contributors to greater adoption of flow chemistry in the country. Regional firm Uniqsis announced that China’s academic segment is the main reason for increased demand for the company’s FlowLab, FlowSyn, and modular-based flow chemistry reactor systems.

In September 2024, Wanhua Chemical Group (Wanhua), a leading supplier of chemical innovative solutions from China, and Air Liquide entered a deal in which the latter will pay Wanhua EUR 60 million for taking over and operating the Air Separation Unit (ASU) previously owned by Wanhua.

Flow Chemistry Market: Competitive Analysis

The global flow chemistry market is led by players like:

- HEL Group

- IDEX Health & Science

- Biotage AB

- Dolomite Microfluidics

- CEM Corporation

- Asynt Ltd.

- AM Technology

- Chemtrix B.V.

- Syrris Ltd

- Fluence Technologies

- Vapourtec Ltd

- YMC Co. Ltd.

- ThalesNano Inc.

- Corning Inc.

- Uniqsis Ltd.

The global flow chemistry market is segmented as follows:

By Application

- Pharmaceutical Synthesis

- Chemical Synthesis

- Energy Conversion

- Material Science

- Others

By Purification Method

- Distillation

- Chromatography

- Membrane Filtration

- Crystallization

- Liquid-Liquid Extraction

- Others

By Reactor

- Oscillatory Flow Reactors

- Microreactors

- Photochemical Reactors

- Droplet-Based Reactors

- Packed-Bed Reactors

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Flow chemistry is a type of chemical process that involves the use of tubing or channel systems to facilitate a chemical reaction.

The global flow chemistry market is projected to witness high growth due to the increasing use of technology in the pharmaceutical and drug discovery industries.

According to study, the global flow chemistry market size was worth around USD 18.14 billion in 2023 and is predicted to grow to around USD 44.83 billion by 2032.

The CAGR value of the flow chemistry market is expected to be around 10.58% during 2024-2032.

The global flow chemistry market is led by Asia-Pacific. In 2023, the region dominated nearly 45.01% of the global revenue, with China, India, South Korea, and Japan acting as the major revenue generators.

The global flow chemistry market is led by players like HEL Group, IDEX Health & Science, Biotage AB, Dolomite Microfluidics, CEM Corporation, Asynt Ltd., AM Technology, Chemtrix B.V., Syrris Ltd, Fluence Technologies, Vapourtec Ltd, YMC Co. Ltd., ThalesNano Inc., Corning Inc., and Uniqsis Ltd.

The report explores crucial aspects of the flow chemistry market including a detailed discussion of existing growth factors and restraints while also browsing future growth opportunities and challenges that impact the market.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed