Conditioning Monitoring Product Market Size, Share, Trends, Growth 2034

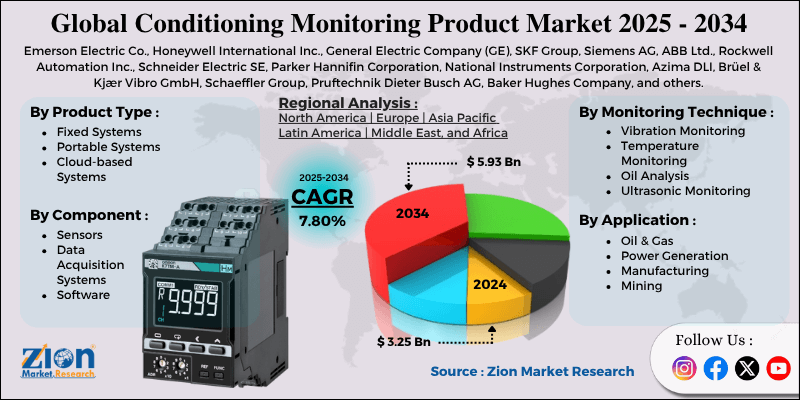

Conditioning Monitoring Product Market By Product Type (Fixed Systems, Portable Systems, Cloud-based Systems), By Component (Sensors, Data Acquisition Systems, Software), By Monitoring Technique (Vibration Monitoring, Temperature Monitoring, Oil Analysis, Ultrasonic Monitoring), By Application (Oil & Gas, Power Generation, Manufacturing, Mining), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

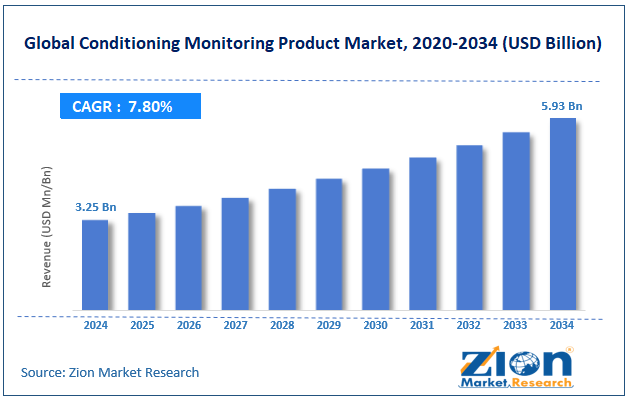

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 3.25 Billion | USD 5.93 Billion | 7.80% | 2024 |

Conditioning Monitoring Product Industry Perspective:

The global conditioning monitoring product market size was worth around USD 3.25 billion in 2024 and is predicted to grow to around USD 5.93 billion by 2034, with a compound annual growth rate (CAGR) of roughly 7.80% between 2025 and 2034.

Key Insights:

- As per the analysis shared by our research analyst, the global conditioning monitoring product market is estimated to grow annually at a CAGR of around 7.80% over the forecast period (2025-2034)

- In terms of revenue, the global conditioning monitoring product market size was valued at around USD 3.25 billion in 2024 and is projected to reach USD 5.93 billion by 2034.

- The conditioning monitoring product market is projected to grow significantly due to increasing industrial automation and digitization, the growth of IIoT (Industrial Internet of Things) applications, and surging demand in the energy, oil & gas, and manufacturing sectors.

- Based on product type, the fixed systems segment is expected to lead the market, while the cloud-based systems segment is expected to grow considerably.

- Based on component, the sensors segment is the dominating segment, while the software segment is projected to witness sizeable revenue over the forecast period.

- Based on the monitoring technique, the vibration monitoring segment leads the market, while the temperature monitoring segment is projected to grow considerably over the forecast period.

- Based on application, the power generation segment is expected to lead the market compared to the manufacturing segment.

- Based on region, North America is projected to dominate the global market during the estimated period, followed by the Asia Pacific.

Conditioning Monitoring Product Market: Overview

Condition monitoring products are the devices and systems that assess the performance and health of machinery in real-time. They detect changes in parameters like pressure, temperature, and noise to predict possible failures before they happen. These solutions improve equipment reliability, optimize maintenance timelines, and reduce unplanned downtime in diverse major industries. The global conditioning monitoring product market is poised for notable growth due to the increasing focus on predictive maintenance, the integration of smart sensors and IoT, and the expansion of industrial automation.

Industries are progressively adopting predictive maintenance tactics to predict equipment failures before they happen. This move reduces unplanned downtime, extends asset lifespans, and reduces maintenance costs. As companies seek higher productivity, the demand for condition monitoring tools has increased in crucial operations.

Moreover, IoT-based sensors enable continuous data collection from machines, allowing real-time insights into health and performance. These smart devices help detect anomalies early, avoiding operational disturbances. The connectivity and scalability of IoT solutions are making condition monitoring more efficient and accessible.

Furthermore, as industries adopt automation to improve productivity and precision, monitoring equipment health becomes vital. Automation systems depend on predictive tools and sensors to avert disturbances in production. This trend fuels demand for integrated monitoring systems in process and manufacturing industries.

Nevertheless, the global market faces limitations due to factors such as high initial integration and installation costs, as well as a lack of skilled personnel. The setup of advanced condition monitoring systems comprises significant investment in software, hardware, and training. Several medium and small-sized businesses struggle to justify these upfront costs. This cost obstacle slows adoption, mainly in cost-sensitive industries.

Similarly, the successful implementation of monitoring systems needs skilled professionals to interpret complex data. Yet, there is a lack of a trained workforce capable of managing these solutions. This skill gap hinders the full potential of predictive maintenance programs. Still, the global conditioning monitoring product industry benefits from several favorable factors, such as the growing adoption of Industry 4.0 technologies and the mounting demand for cloud-based and wireless solutions. The growth of Industry 4.0 is transforming conventional manufacturing into connected and smart systems. Condition monitoring integrated with automated analytics and digital twins improves operational visibility. This convergence offers substantial growth potential for technology providers.

Additionally, wireless and cloud technologies are enabling remote equipment monitoring with minimal infrastructure. This streamlines implementation and cost-efficiency in distributed facilities. Hence, demand for cloud-based and flexible condition monitoring platforms is surging.

Conditioning Monitoring Product Market Dynamics

Growth Drivers

How is the growing focus on predictive maintenance fueling the growth of the conditioning monitoring product market?

Predictive maintenance is becoming a key strategy to extend equipment life and reduce operational costs. Deloitte’s 2025 survey anticipates a 20% annual rise in predictive maintenance adoption in European and North American manufacturing plants. CMPs detect early signs of wear, allowing timely maintenance interventions. Companies are using machine learning within monitoring systems to anticipate failures before they occur. In March 2025, SKF introduced an AI-enhanced bearing monitoring solution that reportedly cuts maintenance costs by 30% in automotive plants.

How are regulatory compliance and safety standards driving the conditioning monitoring product market?

Strict safety standards and regulatory norms in industries like chemicals, energy, and oil & gas are fueling the adoption of CMP, driving the conditioning monitoring product market. Updated ISO and IEC standards focus on predictive monitoring for industrial equipment. Compliance requires continuous tracking of vital assets, which is effectively provided by CMP solutions. Non-compliance may result in operational shutdowns or fines, which could trigger investment in advanced monitoring tools. In August 2025, Shell mandated real-time vibration monitoring on all offshore platforms to comply with updated safety regulations.

Restraints

Cybersecurity and data security concerns negatively impact the market progress

As CMPs progressively use cloud computing, IoT, and real-time data, the risk of data breaches and cyberattacks grows. A 2025 Capgemini report studied that nearly 57% of industrial IoT networks have experienced security incidents, causing companies to hesitate in full CMP deployment. Unauthorized access may disturb operations, create safety risks, or steal IP, while large corporations invest in secure protocols. In August 2025, a German chemical plant faced a ransomware attack that temporarily disabled its monitoring system, underscoring the need for strong CMP cybersecurity.

Opportunities

How do digitalization and smart factory initiatives open lucrative opportunities for the advancement of the conditioning monitoring product market?

The worldwide push for smart manufacturing and Industry 4.0 is fueling substantial adoption of CMP, with economies like India and China promoting industrial digitalization. Frost and Sullivan 2025 anticipates a CAGR of 9.8% for CMP adoption in APAC from 2025 to 2030. Digital factories are dependent on continuous monitoring to minimize unplanned downtime and enhance efficiency.

Recently, Bosch Rexroth introduced AI-enabled conditioning monitoring product solutions for Indian factories in July 2025, aiming to improve predictive maintenance and influence the development of the conditioning monitoring product industry.

Challenges

Uncertain ROI in low-intensity industries restricts the market growth

Industries with low margins or irregular equipment use may find it harder to justify investments in condition monitoring products. According to the reports (2025), sectors like small-scale agriculture or textiles usually experience ROI periods of 3-5 years. This is longer than capital-intensive sectors like energy or automation. This uncertainty slows the adoption of CMP in cost-sensitive regions despite clear long-term advantages. Vendors are now discovering modular or subscription-based CMP solutions to reduce financial hindrances.

Lately, McKinsey (2025) noted that many Latin American SMEs delayed CMP deployment because of unclear short-term returns, underscoring ongoing adoption intricacies.

Conditioning Monitoring Product Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Conditioning Monitoring Product Market |

| Market Size in 2024 | USD 3.25 Billion |

| Market Forecast in 2034 | USD 5.93 Billion |

| Growth Rate | CAGR of 7.80% |

| Number of Pages | 212 |

| Key Companies Covered | Emerson Electric Co., Honeywell International Inc., General Electric Company (GE), SKF Group, Siemens AG, ABB Ltd., Rockwell Automation Inc., Schneider Electric SE, Parker Hannifin Corporation, National Instruments Corporation, Azima DLI, Brüel & Kjær Vibro GmbH, Schaeffler Group, Pruftechnik Dieter Busch AG, Baker Hughes Company, and others. |

| Segments Covered | By Product Type, By Component, By Monitoring Technique, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Conditioning Monitoring Product Market: Segmentation

The global conditioning monitoring product market is segmented based on product type, component, monitoring technique, application, and region.

Based on product type, the global conditioning monitoring product industry is divided into fixed systems, portable systems, and cloud-based systems. The fixed systems segment registered a leading share of the market since industries prefer continuous and real-time monitoring of crucial assets for enhanced reliability.

On the other hand, the cloud-based systems segment holds a second position because of remote monitoring capabilities, integration with predictive analytics, and scalability.

Based on component, the global market is segmented into sensors, data acquisition systems, and software. The sensors segment holds a dominating share since they are vital for collecting real-time data on equipment health in industries.

Conversely, the software segment holds a second-leading share because of the growing use of AI, analytics, and predictive maintenance platforms to interpret sensor data.

Based on the monitoring technique, the global conditioning monitoring product market is segmented into vibration monitoring, temperature monitoring, oil analysis, and ultrasonic monitoring. The vibration monitoring segment registers a significant share of the market since it effectively identifies early mechanical faults in crucial and rotating machinery.

Nonetheless, the temperature monitoring segment holds a second-leading rank due to its broader applicability in tracking overheating and preventing equipment failures in industries.

Based on application, the global market is segmented into oil & gas, power generation, manufacturing, and mining. The power generation segment holds leadership because continuous monitoring of turbines, transformers, and generators is crucial to avoid costly downtime.

However, the manufacturing segment follows the above segment due to the high adoption of predictive maintenance in automated production lines, which reduces operational disturbances and promises efficiency.

Conditioning Monitoring Product Market: Regional Analysis

Why does North America hold a dominant position in the global Conditioning Monitoring Product Market?

North America is projected to maintain its dominant position in the global conditioning monitoring product market owing to advanced industrial infrastructure, early adoption of predictive maintenance technologies, and substantial technological improvements. North America holds a well-established industrial base, comprising oil & gas, manufacturing, and power generation industries. These sectors need continuous monitoring of vital machinery to maintain safety and productivity. Companies in the region are the leaders in adopting preventive and predictive maintenance strategies. Early adoption has created a sophisticated market for cloud-based and fixed monitoring systems. This sophistication offers the region a competitive edge, with the predictive maintenance industry projected to progress at a 12% CAGR by 2030.

Furthermore, the area houses the leading research institutions and technology providers that fuel advancements in AI, sensor technologies, and IoT. Advanced analytics platforms developed here enhance decision-making and fault detection in real-time. North America registers for approximately 40% of worldwide condition monitoring technology patents, underscoring its dominance.

Asia Pacific maintains its position as the second-leading region in the global conditioning monitoring product industry due to rapid industrialization, a growing power and energy sector, and the adoption of advanced technologies. The APAC region, dominated by India, Southeast Asia, and China, is witnessing augmented industrial growth. Manufacturing hubs are increasingly adopting condition monitoring systems to reduce unplanned downtime. This growth in industrial activity is fueling significant demand for CMP products. Moreover, smart grid expansions and renewable energy installations are increasing equipment monitoring requirements. Economies like Japan and India are investing in condition monitoring for generators, turbines, and transmission systems.

Additionally, AI-based analytics, IoT-enabled sensors, and predictive maintenance tools are becoming paramount in industrial operations. Companies are using these solutions to monitor equipment performance in real-time and avoid failures. This technological move is raising the demand for well-developed condition monitoring solutions.

Conditioning Monitoring Product Market: Competitive Analysis

The leading players in the global conditioning monitoring product market are:

- Emerson Electric Co.

- Honeywell International Inc.

- General Electric Company (GE)

- SKF Group

- Siemens AG

- ABB Ltd.

- Rockwell Automation Inc.

- Schneider Electric SE

- Parker Hannifin Corporation

- National Instruments Corporation

- Azima DLI

- Brüel & Kjær Vibro GmbH

- Schaeffler Group

- Pruftechnik Dieter Busch AG

- Baker Hughes Company

Conditioning Monitoring Product Market: Key Market Trends

Adoption of AI and machine learning analytics:

Machine learning and artificial intelligence are used to analyze equipment data patterns. These solutions predict failures before they happen, enhancing maintenance efficiency. AI-based CMP solutions reduce operational costs and improve accuracy.

Shift toward wireless and remote monitoring:

Remote monitoring solutions and wireless sensors are replacing conventional wired systems. This trend enables real-time equipment monitoring without extensive infrastructure changes. Remote monitoring supports industries with geographically dispersed assets like power and oil & gas.

The global conditioning monitoring product market is segmented as follows:

By Product Type

- Fixed Systems

- Portable Systems

- Cloud-based Systems

By Component

- Sensors

- Data Acquisition Systems

- Software

By Monitoring Technique

- Vibration Monitoring

- Temperature Monitoring

- Oil Analysis

- Ultrasonic Monitoring

By Application

- Oil & Gas

- Power Generation

- Manufacturing

- Mining

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Condition monitoring products are the devices and systems that assess the performance and health of machinery in real-time. They detect changes in parameters like pressure, temperature, and noise to predict possible failures before they happen. These solutions improve equipment reliability, optimize maintenance timelines, and reduce unplanned downtime in diverse major industries.

The global conditioning monitoring product market is projected to grow due to the growing adoption of predictive maintenance strategies, increasing focus on asset reliability and uptime optimization, and improvements in wireless and cloud-based monitoring systems.

According to study, the global conditioning monitoring product market size was worth around USD 3.25 billion in 2024 and is predicted to grow to around USD 5.93 billion by 2034.

The CAGR value of the conditioning monitoring product market is expected to be around 7.80% during 2025-2034.

Technological advancements like AI, IoT, and wireless sensors are enhancing real-time monitoring, predictive maintenance, and overall efficiency in the conditioning monitoring product market.

Stringent safety, industrial, and environmental regulations are driving the adoption of condition monitoring products to reduce operational risks and ensure compliance.

North America is expected to lead the global conditioning monitoring product market during the forecast period.

The key players profiled in the global conditioning monitoring product market include Emerson Electric Co., Honeywell International Inc., General Electric Company (GE), SKF Group, Siemens AG, ABB Ltd., Rockwell Automation, Inc., Schneider Electric SE, Parker Hannifin Corporation, National Instruments Corporation, Azima DLI, Brüel & Kjær Vibro GmbH, Schaeffler Group, Pruftechnik Dieter Busch AG, and Baker Hughes Company.

Leading players are adopting strategic initiatives such as partnerships, mergers & acquisitions, regional expansions, and product innovations to strengthen their market presence and reach new customers.

The report examines key aspects of the conditioning monitoring product market, offering a detailed analysis of current growth factors and restraints, as well as future opportunities and challenges that will impact the market.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed