Commercial Single Ply Membrane Market Size, Share, Trends, Growth and Forecast 2034

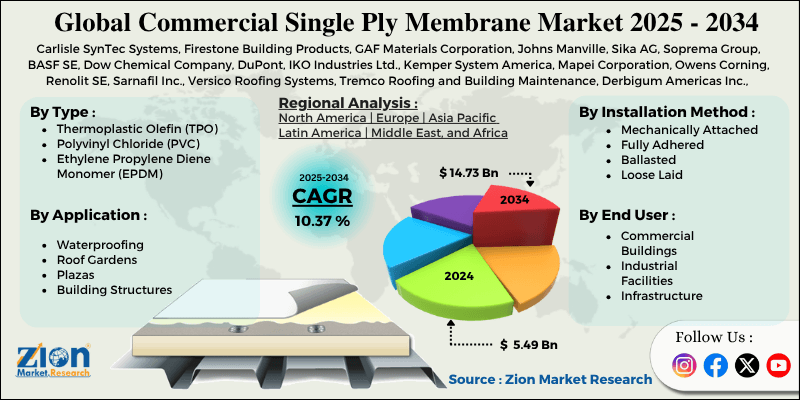

Commercial Single Ply Membrane Market By Type (Thermoplastic Olefin (TPO), Polyvinyl Chloride (PVC), Ethylene Propylene Diene Monomer (EPDM), and Others), By Application (Waterproofing, Roof Gardens, Plazas, Building Structures), By Installation Method (Mechanically Attached, Fully Adhered, Ballasted, Loose Laid), By End-User (Commercial Buildings, Industrial Facilities, Infrastructure), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

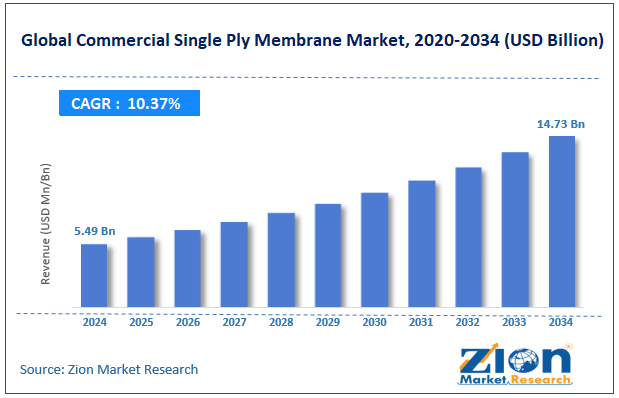

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 5.49 Billion | USD 14.73 Billion | 10.37% | 2024 |

Commercial Single Ply Membrane Industry Perspective:

The global commercial single ply membrane market was valued at approximately USD 5.49 billion in 2024 and is expected to reach around USD 14.73 billion by 2034, growing at a compound annual growth rate (CAGR) of roughly 10.37% between 2025 and 2034.

Commercial Single Ply Membrane Market: Overview

A commercial single ply membrane is a single-layer plastic or rubber sheet used for roofing. It protects buildings from the weather, saves energy, and lasts a long time.

Common types include TPO, PVC, and EPDM, each offering different benefits based on climate and energy needs. These membranes are popular for flat or low-slope roofs in commercial buildings due to their lightweight and easy maintenance.

The growing emphasis on energy-efficient building solutions, increasing renovation activities in the commercial sector, and stringent building code requirements for sustainable materials are expected to drive substantial growth in the global commercial single ply membrane industry over the forecast period.

Key Insights:

- As per the analysis shared by our research analyst, the global commercial single ply membrane market is estimated to grow annually at a CAGR of around 10.37% over the forecast period (2025-2034)

- In terms of revenue, the global commercial single ply membrane market size was valued at around USD 5.49 billion in 2024 and is projected to reach USD 14.73 billion by 2034.

- The commercial single ply membrane market is projected to grow significantly due to rising urban infrastructure development, increased investment in industrial roofing systems, and rising awareness of lifecycle cost savings.

- Based on type, Thermoplastic Olefin (TPO) membranes will continue to lead the global market.

- Based on the application, waterproofing leads the market with the largest revenue share.

- Based on the installation method, mechanically attached systems are anticipated to command the largest market share.

- Based on the end user, commercial buildings are expected to lead the market during the forecast period.

- Based on region, North America is projected to lead the global market during the forecast period.

Commercial Single Ply Membrane Market: Growth Drivers

Sustainable building standards and climate resilience demands

The global commercial single ply membrane industry is growing due to rising demand for weather-resistant building envelopes and the increasing influence of green building certification requirements across sectors. Sustainable certifications impact new commercial construction in developed markets, marking a significant shift from traditional roofing methods.

Energy codes have redefined roofing specifications, making reflective membranes a standard feature. Climate adaptation strategies are boosting adoption rates among property owners and facility managers.

Research indicates resilience metrics include extreme weather resistance, leading to steady, long-term demand rather than periodic replacement cycles.

Material innovation and installation efficiency enhancement

The commercial single ply membrane market has changed industry product formulation and application methods. Multi-function membranes have added energy-saving features and operational benefits for building owners. Advanced adhesives and welding have reduced installation time and improved long-term performance in different climate zones.

Material customization allows for regional climate optimization, building-specific features, and jurisdiction compliance to add value beyond waterproofing. Manufacturing improvements like reducing volatile organic compounds and increasing recycled content are implemented to meet the market demand for green building products.

Commercial Single Ply Membrane Market: Restraints

Raw material volatility and the scarcity of installation expertise

Despite the demand, the commercial single ply membrane market has supply chain instability and skilled labor issues. The petroleum-based membrane formulations have significant price fluctuations, and material cost changes over short periods affect project budgets and contractor margins.

Installation quality dependencies create operational challenges, proper training and certification are a significant barrier to consistent performance, and require considerable investment in workforce development.

Additionally, lead time variability for key components such as adhesives and insulation boards disrupts project timelines and complicates contractor scheduling.

Commercial Single Ply Membrane Market: Opportunities

Integrated system approaches and emerging market expansion

The commercial single ply membrane industry has strong growth opportunities through advanced roofing system development and entry into new regional markets.

More building owners are considering long-term costs, which increases demand for durable and efficient membrane solutions. Reflective membranes are also gaining popularity as cities focus on reducing urban heat, helping save energy while supporting climate goals.

Membranes with built-in sensors fit into the growing trend of smart buildings, offering extra value to manufacturers and contractors. As interest in high-tech and energy-saving roofing grows, customer expectations for commercial buildings are shifting.

Commercial Single Ply Membrane Market: Challenges

Market commoditization and performance verification limitations

The commercial single ply membrane market faces challenges in staying profitable because many buyers still focus more on upfront costs than on long-term performance.

Choosing the right type of membrane is technically complex, especially when factoring in different climates and building types, and it isn't easy to make the right decisions when working with many stakeholders.

Traditional roofing options remain tough competition because they are often cheaper, well-known, and easier for contractors to install. Buyers tend to be price-sensitive for basic projects but are willing to pay more for specialized needs, making it hard for manufacturers to manage both budget-friendly and high-end product lines simultaneously.

Commercial Single Ply Membrane Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Commercial Single Ply Membrane Market |

| Market Size in 2024 | USD 5.49 Billion |

| Market Forecast in 2034 | USD 14.73 Billion |

| Growth Rate | CAGR of 10.37% |

| Number of Pages | 212 |

| Key Companies Covered | Carlisle SynTec Systems, Firestone Building Products, GAF Materials Corporation, Johns Manville, Sika AG, Soprema Group, BASF SE, Dow Chemical Company, DuPont, IKO Industries Ltd., Kemper System America, Mapei Corporation, Owens Corning, Renolit SE, Sarnafil Inc., Versico Roofing Systems, Tremco Roofing and Building Maintenance, Derbigum Americas Inc., FiberTite Roofing Systems, Henry Company, and others. |

| Segments Covered | By Type, By Application, By Installation Method, By End User, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Commercial Single Ply Membrane Market: Segmentation

The global commercial single ply membrane market is segmented into type, application, installation method, end user, and region.

Based on type, the market is segregated into Thermoplastic Olefin (TPO), Polyvinyl Chloride (PVC), Ethylene Propylene Diene Monomer (EPDM), and others. TPO membranes lead the market due to their balanced performance characteristics, competitive pricing structures, excellent UV and ozone resistance, and reduced environmental impact compared to alternative formulations.

Based on the application, the commercial single ply membrane industry is classified into waterproofing, roof gardens, plazas, and building structures. Waterproofing holds the largest market share due to fundamental building protection requirements, stringent building code mandates, moisture-related damage prevention priorities, and long-term asset preservation concerns across diverse commercial property types.

Based on the installation method, the commercial single ply membrane market is divided into mechanically attached, fully adhered, ballasted, and loose-laid systems. Due to installation speed advantages, labor cost optimization, system reliability across varying substrates, and suitability for multiple building types and geometries, the mechanically attached installation will lead the market during the forecast period.

Based on the end user, the industry is categorized into commercial buildings, industrial facilities, and infrastructure applications. Commercial building applications are expected to lead the market due to large roof areas, significant renovation activity, energy efficiency priorities, and regular maintenance programs compared to other categories.

Commercial Single Ply Membrane Market: Regional Analysis

North America to lead the market

North America leads the commercial single ply membrane market due to its large number of commercial buildings, strict energy regulations, and well-established roofing specifications.

The region holds around 40% of the global market share, with the U.S. being the top user of single ply roofing systems. These membranes are used in about 65–70% of low-slope commercial roofs in the U.S. because of their energy efficiency and ease of installation.

Strict building codes often require reflective roofing to cut energy use, and high labor costs make single ply systems attractive due to quicker installation. The reroofing market adds steady demand, especially for lightweight materials suitable for layering. In North America, buyers value strong warranties and reliable performance, leading to consistent product preferences and brand loyalty.

Europe is to maintain a substantial market share.

Europe continues to hold a strong share in the commercial single ply membrane market, driven by strict environmental rules, energy efficiency standards, and a growing focus on circular economy practices. Countries like Germany, France, the UK, and Nordic nations lead adoption with tough building performance demands.

Unlike North America, where cost plays a bigger role, European markets often prioritize environmental impact and long-term durability, especially end-of-life recyclability.

As cities grow denser, lightweight roofing options for renovations are in higher demand, boosting opportunities for single ply systems. European buyers prefer complete, integrated roofing solutions to standalone products, setting a different trend from global norms.

Recent Market Developments:

- In March 2025, GAF introduced its enhanced TPO membrane featuring a proprietary stabilizer package that extends service life by up to 25% while maintaining solar reflectivity over longer than conventional formulations.

- In January 2025, Sika Corporation completed the acquisition of HPS North America, Inc., a regional membrane manufacturer, expanding its production capacity by 30% and strengthening its position in the commercial roofing sector across multiple product categories.

Commercial Single Ply Membrane Market: Competitive Analysis

The global commercial single ply membrane market is led by players like:

- Carlisle SynTec Systems

- Firestone Building Products

- GAF Materials Corporation

- Johns Manville

- Sika AG

- Soprema Group

- BASF SE

- Dow Chemical Company

- DuPont

- IKO Industries Ltd.

- Kemper System America

- Mapei Corporation

- Owens Corning

- Renolit SE

- Sarnafil Inc.

- Versico Roofing Systems

- Tremco Roofing and Building Maintenance

- Derbigum Americas Inc.

- FiberTite Roofing Systems

- Henry Company

The global commercial single ply membrane market is segmented as follows:

By Type

- Thermoplastic Olefin (TPO)

- Polyvinyl Chloride (PVC)

- Ethylene Propylene Diene Monomer (EPDM)

- Others

By Application

- Waterproofing

- Roof Gardens

- Plazas

- Building Structures

By Installation Method

- Mechanically Attached

- Fully Adhered

- Ballasted

- Loose Laid

By End User

- Commercial Buildings

- Industrial Facilities

- Infrastructure

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

A commercial single ply membrane is a synthetic roofing material installed in one layer. It combines plastic or rubber-based materials with reinforcement to protect buildings from weather, improve energy efficiency, and provide long-lasting performance in different climates.

The commercial single ply membrane market is expected to be driven by increasing commercial construction activity, growing renovation and reroofing projects, stringent energy code requirements, rising demand for sustainable building materials, technological advancements in membrane formulations, and greater emphasis on building resilience against extreme weather events.

According to our study, the global commercial single ply membrane market was worth around USD 5.49 billion in 2024 and is predicted to grow to around USD 14.73 billion by 2034.

The CAGR value of the commercial single ply membrane market is expected to be around 10.37% during 2025-2034.

The global commercial single ply membrane market will register the highest growth in North America during the forecast period.

Key players in the commercial single ply membrane market include Carlisle SynTec Systems, Firestone Building Products, GAF Materials Corporation, Johns Manville, Sika AG, Soprema Group, BASF SE, Dow Chemical Company, DuPont, IKO Industries Ltd., Kemper System America, Mapei Corporation, Owens Corning, Renolit SE, Sarnafil Inc., Versico Roofing Systems, Tremco Roofing and Building Maintenance, Derbigum Americas Inc., FiberTite Roofing Systems, and Henry Company.

The report comprehensively analyzes the commercial single ply membrane market, including an in-depth discussion of market drivers, restraints, emerging trends, regional dynamics, and future growth opportunities. It also examines competitive dynamics, technological innovations, product formulation evolution, and the changing specifier and building owner preferences shaping the commercial single ply membrane industry ecosystem.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed