Stinging Nettle Fibers Market Size, Share, Trends, Growth & Forecast 2034

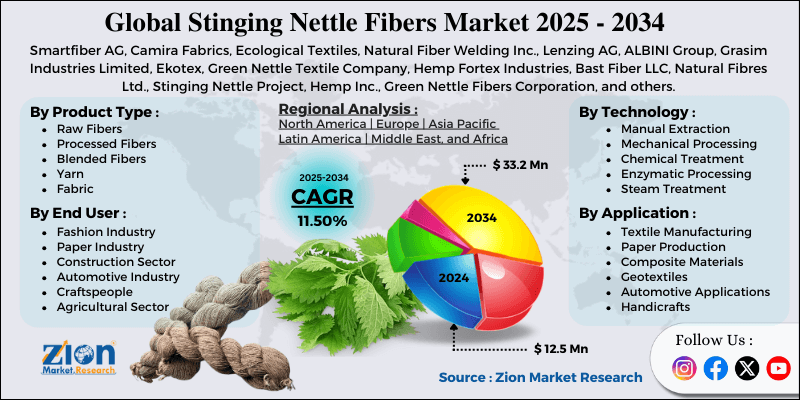

Stinging Nettle Fibers Market By Product Type (Raw Fibers, Processed Fibers, Blended Fibers, Yarn, Fabric, and Others), By Technology (Manual Extraction, Mechanical Processing, Chemical Treatment, Enzymatic Processing, Steam Treatment, and Others), By Application (Textile Manufacturing, Paper Production, Composite Materials, Geotextiles, Automotive Applications, and Handicrafts), By End-User (Fashion Industry, Paper Industry, Construction Sector, Automotive Industry, Craftspeople, and Agricultural Sector), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

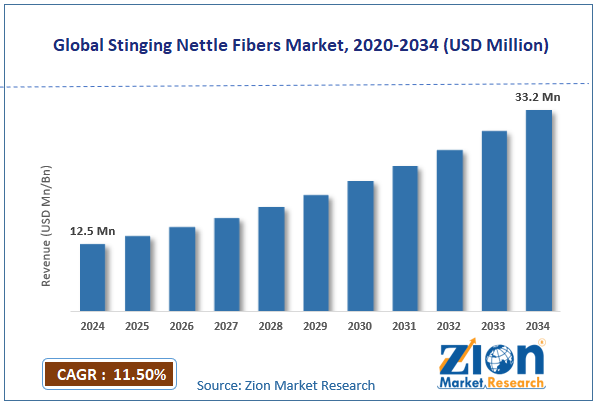

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 12.5 Million | USD 33.2 Million | 11.50% | 2024 |

Stinging Nettle Fibers Industry Perspective:

The global stinging nettle fibers market size was worth approximately USD 12.5 million in 2024 and is projected to grow to around USD 33.2 million by 2034, with a compound annual growth rate (CAGR) of roughly 11.50% between 2025 and 2034.

Key Insights:

- As per the analysis shared by our research analyst, the global stinging nettle fibers market is estimated to grow annually at a CAGR of around 11.50% over the forecast period (2025-2034).

- In terms of revenue, the global stinging nettle fibers market size was valued at approximately USD 12.5 million in 2024 and is projected to reach USD 33.2 million by 2034.

- The stinging nettle fibers market is projected to grow significantly due to increasing sustainability concerns in the textile industry and rising consumer preference for eco-friendly natural materials.

- Based on product type, the processed fibers segment is expected to lead the stinging nettle fibers market, while the blended fibers segment is anticipated to experience significant growth.

- Based on technology, the mechanical processing segment is expected to lead the stinging nettle fibers market, while the enzymatic processing segment is anticipated to witness notable growth.

- Based on application, the textile manufacturing segment is the dominating segment, while the composite materials segment is projected to witness sizeable revenue over the forecast period.

- Based on end-user, the fashion industry segment is expected to lead the market compared to the craftspeople segment.

- Based on region, Europe is projected to dominate the global stinging nettle fibers market during the estimated period, followed by North America.

Stinging Nettle Fibers Market: Overview

Stinging nettle fiber is a natural plant-based fiber obtained from the stems of the stinging nettle plant. It is considered a sustainable and eco-friendly substitute for common textile and synthetic materials. It offers strong physical properties, natural antibacterial benefits, and good moisture control, making it suitable for various uses across different sectors. Nettle fiber has been used for many centuries in traditional cultures, but its popularity has decreased during the Industrial Revolution, when cotton and synthetic fibers became more dominant.

Recent advancements in extraction and processing have brought renewed interest in nettle fiber because it requires very little pesticide, fertilizer, and water during cultivation. The plant grows widely in many regions, is often seen as a weed, and can be harvested in a sustainable manner without replacing food crops. Nettle fiber shares similarities with flax and hemp, providing a soft texture when processed correctly, along with durability and strength. It can also be blended with other natural or synthetic fibers to improve fabric performance. Beyond textiles, nettle fiber is used in paper, composite materials, and several industrial products. Its cultivation supports soil health, biodiversity, carbon absorption, and rural employment.

The increasing environmental awareness and growing demand for sustainable materials are expected to drive growth in the stinging nettle fibers market throughout the forecast period.

Stinging Nettle Fibers Market Dynamics

Growth Drivers

How are rising environmental concerns and the sustainable textile movement increasing demand for the nettle fiber market?

The stinging nettle fiber industry is growing as the textile industry looks for eco-friendly options instead of resource-intensive fibers with high environmental impact. Cotton farming uses large amounts of water, heavy pesticide use, and wide land areas, causing serious ecological concerns among aware consumers and brands. Synthetic fibers made from petroleum cause plastic pollution, microfiber release, and high carbon emissions across their life cycle. Stinging nettle grows with very little water, no pesticide use, and can survive on poor soil not used for food crops. Cultivation improves soil quality, prevents erosion, and supports the growth of insects and biodiversity.

Harvesting nettle does not harm the roots, allowing for natural regrowth for repeated harvests. Processing nettle fiber needs less energy and fewer chemicals compared to cotton or synthetic fiber production. The fiber is fully biodegradable, helping reduce textile waste in landfills and oceans. Fashion brands seeking to demonstrate environmental responsibility are choosing sustainable materials. Government rules in many countries support renewable resources and reduce polluting practices. Certifications and sustainability standards promote the use of low-impact natural fibers.

Circular economy and regenerative agriculture trend

The global stinging nettle fibers market is growing as circular economy ideas gain importance and industries look for materials suited to regenerative production. Nettle fiber fits circular economy goals due to renewable sourcing, full biodegradability, and strong lifecycle management. The plant can be grown using organic farming methods, which maintain ecosystem health and avoid harmful chemicals. Fiber extraction can use plant parts once seen as waste, thereby increasing resource efficiency and creating extra income sources. Used nettle textiles can be composted at the end of life, returning nutrients to soil instead of adding to waste. Brands working on circular fashion see nettle fiber as a good choice for closed-loop product systems.

Industrial ecology models benefit from a local nettle fiber supply linking farming with manufacturing. Textile waste reduction efforts value its efficient processing and low byproduct levels. Regenerative farming groups support the cultivation of nettle for its benefits to soil health and carbon capture. Policy support for bio-based economies and research on plant fibers is further encouraging industry growth.

Restraints

Processing challenges and limited infrastructure

A major challenge for the stinging nettle fibers industry is the complex processing needs, limited industrial support, and difficulty in achieving consistent quality on a large scale. Extracting fibers from nettle stems needs specialized equipment and methods different from those used for cotton or synthetic fiber systems. The retting process, which separates fibers from stems, needs careful control of timing, moisture, and temperature for good results.

Inconsistent quality from different harvests creates problems for manufacturers who need uniform material for smooth production. Turning raw nettle fibers into yarns and fabrics suitable for modern use often needs machine upgrades or new equipment. Few processing facilities exist, limiting capacity and access for users. Transitioning from small-scale production to industrial volumes is challenging while maintaining quality and controlling costs. Seasonal harvesting affects supply, and blending with other fibers needs testing and expertise. Weak quality standards and high investment needs for new infrastructure also hold back industry growth.

Opportunities

Will innovation in the fashion industry create opportunities for stinging nettle fiber market players?

The stinging nettle fibers market is seeing strong opportunities as fashion brands, designers, and textile innovators explore alternative materials with unique qualities and clear sustainability value. Luxury fashion houses are using nettle fiber in their premium collections, giving it a high-end image and raising interest in eco-friendly materials. Sustainable fashion movements and conscious shoppers are seeking clothing made from new plant-based fibers that offer environmental benefits. Designer partnerships with fiber producers are gaining attention and showing creative uses for nettle textiles.

Fashion events and exhibitions featuring nettle fiber products are increasing awareness among buyers, media, and trend experts. Sports and outdoor brands appreciate nettle fiber for natural moisture-wicking and antibacterial performance. Regions with a history in natural fiber work are returning to nettle cultivation and processing. Artisan makers are producing handcrafted nettle goods for consumers who value tradition and authenticity.

Challenges

How are building supply chains and achieving cost competitiveness creating stinging nettle fibers market limitations?

The stinging nettle fibers industry faces key challenges in building a steady supply chain, increasing production levels, and competing on cost with established fiber markets. Nettle farming for fiber needs farmer training, technical support, and investment in planting materials and harvesting tools. Coordinating harvests across many small growers to provide a consistent supply for processing units is difficult, and the transport of bulky plant material from farms to processing centers adds extra expense. Processing remains costly due to low production volumes, specialized equipment needs, and limited processors, so final product prices must recover costs while still appealing to buyers.

Clear quality grading and fair pricing for raw stems can support stronger relationships between growers and processors, while vertical integration from farming to finished goods may reduce coordination issues but requires high capital. Consumer education, certification fees, climate risks affecting harvests, and limited research funding for efficiency and quality improvements all add pressure on this growing industry.

Stinging Nettle Fibers Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Stinging Nettle Fibers Market |

| Market Size in 2024 | USD 12.5 Million |

| Market Forecast in 2034 | USD 33.2 Million |

| Growth Rate | CAGR of 11.50% |

| Number of Pages | 213 |

| Key Companies Covered | Smartfiber AG, Camira Fabrics, Ecological Textiles, Natural Fiber Welding Inc., Lenzing AG, ALBINI Group, Grasim Industries Limited, Ekotex, Green Nettle Textile Company, Hemp Fortex Industries, Bast Fiber LLC, Natural Fibres Ltd., Stinging Nettle Project, Hemp Inc., Green Nettle Fibers Corporation, and others. |

| Segments Covered | By Product Type, By Technology, By Application, By End User, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Stinging Nettle Fibers Market: Segmentation

The global stinging nettle fibers market is segmented based on product type, technology, application, end-user, and region.

Based on product type, the global stinging nettle fibers industry is segregated into raw fibers, processed fibers, blended fibers, yarn, fabric, and others. Processed fibers lead the market due to their ready usability in textile manufacturing, consistent quality characteristics, and the elimination of additional preparation steps for end-users.

Based on technology, the industry is classified into manual extraction, mechanical processing, chemical treatment, enzymatic processing, steam treatment, and others. Mechanical processing leads the market due to its scalability for commercial production and cost-effectiveness compared to manual methods.

Based on application, the global stinging nettle fibers market is segmented into textile manufacturing, paper production, composite materials, geotextiles, automotive applications, and handicrafts. The textile manufacturing sector is expected to lead the market during the forecast period, driven by growing interest in sustainable materials from the fashion industry and increasing consumer demand for eco-friendly clothing.

Based on end-user, the global market is divided into the fashion industry, paper industry, construction sector, automotive industry, craftspeople, and agricultural sector. The fashion industry holds the largest market share due to strong sustainability commitments and willingness to invest in innovative materials.

Regional Analysis

Europe holds a leading position in the global market

Europe holds a leading position in the stinging nettle fibers market due to strong environmental awareness, supportive policies, and a long history of natural fiber production. Many European countries have strict sustainability rules and standards that encourage the use of low-impact renewable materials. Government funding and farming subsidies enable farmers to transition to alternative fiber crops, such as stinging nettles, while research centers across the region investigate the properties of nettle fiber, processing methods, and potential new applications.

Europe has a rich textile heritage, with a past use of nettle fibers, so cultural acceptance and awareness already exist. Strong organic farming movements and consumer preference for natural products create a ready market for nettle goods. Fashion hubs like Paris, Milan, and London drive sustainable fashion trends and encourage designers to explore alternative materials. Collaboration between textile manufacturers, research bodies, and farming groups supports knowledge exchange and innovation.

EU programs promoting bioeconomy growth and circular economy goals provide direction and resources, and sustainable fashion brands across Europe offer clear retail channels for nettle textiles. Growing interest from eco-focused influencers and media is also boosting the visibility of nettle fiber. With the rising demand for responsible fashion in Europe, the region is well placed to drive global growth for nettle-based products.

What factors are driving North America’s increasing interest in the stinging nettle fiber market?

North America is showing growing interest in the stinging nettle fibers market as sustainability awareness increases and material innovators explore new plant-based options. Environmental movements and climate concerns are encouraging brands to rethink material sourcing and choose lower-impact fibers, while many sustainable fashion labels in the region are adding plant-based textiles into their collections and storytelling. Universities researching sustainable farming and material science are studying nettle cultivation and better processing methods, and Indigenous communities with knowledge of native plant fibers are sharing their cultural practices for modern use.

Consumer interest in natural products, organic textiles, and eco-friendly shopping is helping create steady demand for nettle fiber goods. Industry groups and fiber associations are incorporating alternative fibers into their training programs, and some farming areas are seeing nettle as a promising crop for generating income growth.

Green building sectors are exploring nettle fiber for insulation and bio-composites, and outdoor wear brands value its natural moisture control and antimicrobial qualities for performance clothing. Artisan markets are also spreading awareness through handmade nettle products, and rules on textile waste and microplastic pollution are pushing brands to adopt biodegradable fibers. In North America, collaboration between farmers, researchers, and brands has strong potential to become a key growth region for nettle fiber products.

Recent Market Developments:

- In June 2025, MIC spa launched HILAYA MIC, a yarn blending organic cotton and Himalayan nettle fibers, marking a commercial step for nettle-based textiles.

- In August 2025, Haelixa and Nettle Circle announced a strategic partnership to apply DNA-tracing technology to nettle fibers, enabling full supply-chain traceability for nettle-based textiles.

Stinging Nettle Fibers Market: Competitive Analysis

The leading players in the global stinging nettle fibers market are:

- Smartfiber AG

- Camira Fabrics

- Ecological Textiles

- Natural Fiber Welding Inc.

- Lenzing AG

- ALBINI Group

- Grasim Industries Limited

- Ekotex

- Green Nettle Textile Company

- Hemp Fortex Industries

- Bast Fiber LLC

- Natural Fibres Ltd.

- Stinging Nettle Project

- Hemp Inc.

- Green Nettle Fibers Corporation

The global stinging nettle fibers market is segmented as follows:

By Product Type

- Raw Fibers

- Processed Fibers

- Blended Fibers

- Yarn

- Fabric

- Others

By Technology

- Manual Extraction

- Mechanical Processing

- Chemical Treatment

- Enzymatic Processing

- Steam Treatment

- Others

By Application

- Textile Manufacturing

- Paper Production

- Composite Materials

- Geotextiles

- Automotive Applications

- Handicrafts

By End User

- Fashion Industry

- Paper Industry

- Construction Sector

- Automotive Industry

- Craftspeople

- Agricultural Sector

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Stinging nettle fiber is a natural plant-based fiber obtained from the stems of the stinging nettle plant. It is considered a sustainable and eco-friendly substitute for common textile and synthetic materials.

The global stinging nettle fibers market is projected to grow due to increasing environmental awareness, rising demand for sustainable textile materials, growing circular economy initiatives, and expanding applications beyond traditional textile uses into composite materials and industrial products.

According to a study, the global stinging nettle fibers market size was worth around USD 12.5 million in 2024 and is predicted to grow to around USD 33.2 million by 2034.

The CAGR value of the stinging nettle fibers market is expected to be around 11.50% during 2025-2034.

Europe is expected to lead the global stinging nettle fibers market during the forecast period.

The major players profiled in the global stinging nettle fibers market include Smartfiber AG, Camira Fabrics, Ecological Textiles, Natural Fiber Welding Inc., Lenzing AG, ALBINI Group, Grasim Industries Limited, Ekotex, Green Nettle Textile Company, Hemp Fortex Industries, Bast Fiber LLC, Natural Fibres Ltd., Stinging Nettle Project, Hemp Inc., and Green Nettle Fibers Corporation.

The report examines key aspects of the stinging nettle fibers market, including a detailed analysis of existing growth factors and restraints, as well as an examination of future growth opportunities and challenges that will impact the market.

In the stinging nettle fibers market, growth is supported by strict environmental regulations promoting low-impact natural materials, restrictions on harmful chemicals in textiles, and policies encouraging renewable resource use. Government sustainability standards, circular economy policies, and regulations targeting textile waste and microplastic pollution are pushing industries toward biodegradable alternatives such as nettle fibers.

In the stinging nettle fibers market, macroeconomic factors such as rising consumer spending on sustainable products, government incentives for green industries, and increasing raw material and energy costs will shape future growth.

In the stinging nettle fibers market, investment and partnership opportunities lie in farmer–manufacturer collaborations, processing technology upgrades, and brand alliances for sustainable product development.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed