Packaging Straps and Buckles Market Size, Share, Trends, Growth 2034

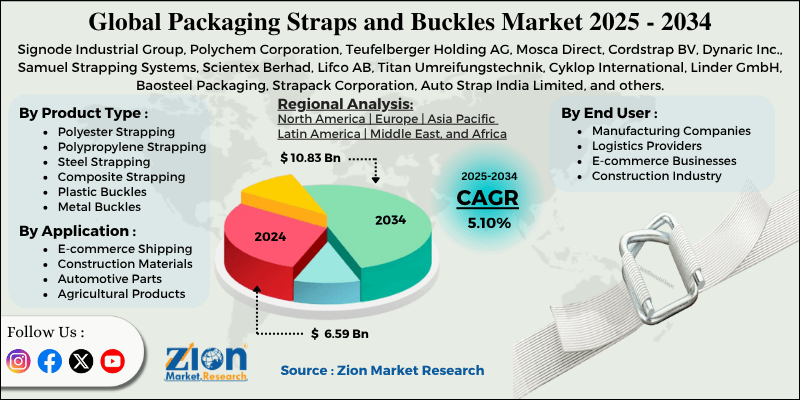

Packaging Straps and Buckles Market By Product Type (Polyester Strapping, Polypropylene Strapping, Steel Strapping, Composite Strapping, Plastic Buckles, Metal Buckles), By Application (Heavy-Duty Industrial Packaging, E-commerce Shipping, Construction Materials, Automotive Parts, Agricultural Products, Logistics and Transportation), By End User (Manufacturing Companies, Logistics Providers, E-commerce Businesses, Construction Industry, Agricultural Suppliers, Shipping Companies), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

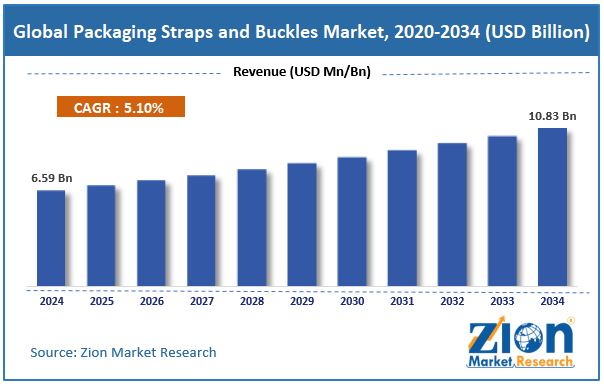

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 6.59 Billion | USD 10.83 Billion | 5.10% | 2024 |

Packaging Straps and Buckles Industry Perspective:

The global packaging straps and buckles market size was worth approximately USD 6.59 billion in 2024 and is projected to grow to around USD 10.83 billion by 2034, with a compound annual growth rate (CAGR) of roughly 5.10% between 2025 and 2034. The report analyzes the global packaging straps and buckles market's drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the retail earplugs industry.

Key Insights:

- As per the analysis shared by our research analyst, the global packaging straps and buckles market is estimated to grow annually at a CAGR of around 5.10% over the forecast period (2025-2034).

- In terms of revenue, the global packaging straps and buckles market size was valued at approximately USD 6.59 billion in 2024 and is projected to reach USD 10.83 billion by 2034.

- The packaging straps and buckles market is projected to grow significantly due to the expansion of global logistics networks and the rise of automated packaging system initiatives.

- Based on product type, the polyester strapping segment is expected to lead the packaging straps and buckles market, while the composite strapping segment is anticipated to experience significant growth.

- Based on application, the heavy-duty industrial packaging segment is the dominating segment, while the e-commerce shipping segment is projected to witness sizeable revenue over the forecast period.

- Based on end-user, the manufacturing companies segment is expected to lead the market compared to the agricultural suppliers’ segment.

- Based on region, North America is projected to dominate the global packaging straps and buckles market during the estimated period, followed by Europe.

Packaging Straps and Buckles Market: Overview

Packaging straps and buckles are essential securing tools made to keep packaged goods safe and stable during storage, handling, and transportation. These durable materials combine strong strapping options with reliable fastening systems to maintain load stability and stop cargo from shifting. Common solutions include polyester composite straps, steel reinforcements, and alternative plastics. The market provides a wide range of securement products, such as automatic tensioning systems, manual tools, corner protectors, and reusable fasteners.

To ensure performance, manufacturers use precise extrusion methods, advanced polymer blends, and strict testing under different load conditions. Industry rules and safety standards make sure packaging straps and buckles meet strength needs, resist environmental factors, and support workplace safety while delivering dependable securement and efficiency.

The increasing focus on supply chain security is expected to drive growth in the packaging straps and buckles market throughout the forecast period.

Packaging Straps and Buckles Market Dynamics

Growth Drivers

How is the increase in global trade volume and logistics expansion driving the packaging straps and buckles market growth?

The packaging straps and buckles market is growing as international commerce demands secure cargo containment solutions for safe transportation across extended supply chains. These tools provide stability that stops product damage, lowers insurance claims, and ensures shipping rules are met. With rising cross-border trade activities and container shipping volumes, companies are investing in reliable strapping systems to maintain cargo integrity during long-distance transportation. Celebrity logistics endorsements, social media supply chain showcases, and premium packaging demonstrations are further driving awareness.

Leading shipping companies use high-performance strapping to protect valuable cargo and justify premium logistics pricing. As the global freight industry continues to expand, strapping consumption for international shipping applications is rising steadily. The just-in-time delivery culture, particularly in competitive market conditions and customer satisfaction-driven requirements, is also boosting demand for dependable cargo securing solutions.

Developments in automated strapping technologies and smart packaging integration

The global packaging straps and buckles market is being driven by manufacturers developing automated application systems that improve efficiency while reducing labor requirements and workplace injuries. These innovations include servo-controlled tensioning, integrated cutting mechanisms, and programmable application sequences, which enhance productivity without compromising securing effectiveness.

A key trend is the integration of tracking sensors and load monitoring capabilities in premium strapping applications. These automated practices are gaining popularity not only in manufacturing facilities but also in distribution centers, shipping terminals, and logistics hubs. As companies focus more on efficiency and safety, packaging straps and buckles are vital for modern packaging and automated material handling. This growing emphasis on automation also allows facilities to differentiate themselves in a competitive logistics marketplace while meeting productivity targets.

Restraints

Material cost volatility and equipment investment requirements

A major constraint for the packaging straps and buckles industry is the fluctuating cost of raw materials, which includes petroleum-based polymers, steel commodities, and specialized additives. These price variations often make strapping operations more expensive than alternative securing methods, limiting adoption among budget-conscious packaging operations. These factors prevent 35% to 50% of potential users in price-sensitive market segments from regularly investing in advanced strapping equipment and premium materials. This makes it challenging for packaging straps and buckles to gain widespread acceptance in smaller operations where capital expenditure and equipment maintenance matter most. Technical training requirements for automated strapping systems also discourage adoption among facilities without specialized personnel.

Opportunities

How are sustainability initiatives and recyclable material innovations creating opportunities for the packaging straps and buckles market?

The packaging straps and buckles market is expanding due to material technologies that deliver superior performance while supporting circular economy objectives and environmental responsibility. Advanced bio-based polymers, recyclable steel alternatives, and reusable buckle systems help achieve reliable cargo securement with minimal environmental impact. These innovations make sustainable strapping solutions accessible to environmentally conscious companies and green logistics initiatives.

Additionally, closed-loop recycling programs are integrated with traditional strapping operations to enable material recovery and waste reduction. This combination of performance and sustainability makes packaging straps and buckles attractive not just to large-scale logistics operations but also to eco-conscious shippers and sustainable packaging advocates. This also helps reduce disposal costs and enhances corporate sustainability reporting for environmentally responsible organizations.

Challenges

How are standardization issues and application complexity limiting the growth of the packaging straps and buckles market?

The packaging straps and buckles market faces challenges due to differing standards and varying methods across industries and regions. Many standards make it hard to deploy common equipment, causing compatibility issues and operational challenges. Companies hesitate to buy special strapping tools because of the complexity and training needs.

Without clear use guidelines or global standards, suppliers also struggle to offer full solutions. This shows the need for more standardization and better support. Stronger cooperation between manufacturers, suppliers, and users can reduce complexity and build confidence. Modular tools and universal systems are being tested to fix these issues.

Packaging Straps and Buckles Market: Segmentation

The global packaging straps and buckles market is segmented based on product type, application, end-user, and region. All the segments have been analyzed based on present and future trends and the market is estimated from 2023 to 2030.

Based on product type, the global packaging straps and buckles industry is divided into polyester strapping, polypropylene strapping, steel strapping, composite strapping, plastic buckles, and metal buckles. Polyester strapping leads the market due to its superior tensile strength, weather-resistant properties, and extensive compatibility with automated application equipment and diverse cargo types.

Based on application, the global packaging straps and buckles market is classified into heavy-duty industrial packaging, e-commerce shipping, construction materials, automotive parts, agricultural products, and logistics and transportation. Heavy-duty industrial packaging is expected to lead the market during the forecast period due to its demanding load requirements, critical safety applications, and strong need for reliable cargo containment and transportation security.

Based on end-user, the global market is segmented into manufacturing companies, logistics providers, e-commerce businesses, the construction industry, agricultural suppliers, and shipping companies. Manufacturing companies hold the largest market share due to their extensive packaging volumes, diverse product portfolios, and consistent demand for reliable cargo securing solutions in production and distribution operations.

The Regional, this segment includes the current and forecast demand for North America, Europe, Asia Pacific, Latin America,and the Middle East and Africa.

Packaging Straps and Buckles Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Packaging Straps and Buckles Market |

| Market Size in 2024 | USD 6.59 Billion |

| Market Forecast in 2034 | USD 10.83 Billion |

| Growth Rate | CAGR of 5.10% |

| Number of Pages | 214 |

| Key Companies Covered | Signode Industrial Group, Polychem Corporation, Teufelberger Holding AG, Mosca Direct, Cordstrap BV, Dynaric Inc., Samuel Strapping Systems, Scientex Berhad, Lifco AB, Titan Umreifungstechnik, Cyklop International, Linder GmbH, Baosteel Packaging, Strapack Corporation, Auto Strap India Limited, and others. |

| Segments Covered | By Product Type, By Application, By End User, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Packaging Straps and Buckles Market: Regional Analysis

North America is expected to lead the market

North America leads the global packaging straps and buckles market due to its advanced logistics infrastructure, strict transportation safety regulations, and high adoption of automated packaging technologies. Approximately 40% of global strapping equipment consumption occurs in this region, with the United States at the forefront, recognized for its distribution networks and cargo securement standards. North American companies value reliable strapping not only for cargo protection but also for regulatory compliance and liability reduction. Strict transportation regulations and workplace safety requirements also ensure the adoption of high-performance strapping solutions. Growing e-commerce activity, infrastructure modernization, and emphasis on supply chain efficiency further fuel regional expansion.

Most innovations in automated application systems, smart monitoring technologies, and sustainable materials originate in North America and influence global industry developments. The rise of cold chain logistics and food packaging safety is further increasing the demand for reliable strapping systems. Regional governments are also supporting technology upgrades to improve cargo handling efficiency. Continuous research and development investments in advanced polymers and stronger buckle systems give North America a competitive edge in the global market.

What factors are contributing to Europe's rapid growth in the global packaging straps and buckles market?

Europe is experiencing strong growth in the packaging straps and buckles market, as manufacturers increasingly seek regulatory-compliant solutions, sustainable materials, and advanced application technologies. Companies in Germany, France, and the UK are leading with high-performance materials and automated systems. Strong factories and modern automation support growth, meeting quality and environmental goals. Rising focus on safety, cargo protection, and sustainability has encouraged the adoption of advanced strapping, including bio-based, reusable, and ergonomic tools.

Strict rules on transport safety and the environment have built a strong base for innovation. More cross-border trade, premium logistics, and green mandates make firms more aware of performance and eco-factors. To meet demand, European firms are working with tech providers to improve automated strapping and eco-friendly solutions. Rapid growth in e-commerce deliveries across the region is also boosting the need for secure and fast strapping solutions. Regional funding for sustainable packaging innovation is driving the development of new products.

Recent Market Developments:

- In May 2025, PAC Strapping Products announced it would showcase its latest strap-dispenser innovation, the DSP-TOOL, at PACK EXPO Las Vegas, aimed at improving operator ergonomics and strapping efficiency under the FROMM Packaging umbrella.

- In May 2025, ErgoStrap launched its reusable Velcro pallet strapping system (ErgoStrap RE), claiming it doubles process speed while eliminating single-use plastic straps in industrial packaging.

Packaging Straps and Buckles Market: Competitive Analysis

The leading players in the global packaging straps and buckles market are:

- Signode Industrial Group

- Polychem Corporation

- Teufelberger Holding AG

- Mosca Direct

- Cordstrap BV

- Dynaric Inc.

- Samuel Strapping Systems

- Scientex Berhad

- Lifco AB

- Titan Umreifungstechnik

- Cyklop International

- Linder GmbH

- Baosteel Packaging

- Strapack Corporation

- Auto Strap India Limited

The global packaging straps and buckles market is segmented as follows:

By Product Type

- Polyester Strapping

- Polypropylene Strapping

- Steel Strapping

- Composite Strapping

- Plastic Buckles

- Metal Buckles

By Application

- Heavy-Duty Industrial Packaging

- E-commerce Shipping

- Construction Materials

- Automotive Parts

- Agricultural Products

- Logistics and Transportation

By End User

- Manufacturing Companies

- Logistics Providers

- E-commerce Businesses

- Construction Industry

- Agricultural Suppliers

- Shipping Companies

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Packaging straps and buckles represent essential securing components designed to provide reliable containment and protection for packaged goods during storage, handling, and transportation processes. These robust materials combine high-tensile strength strapping materials with secure fastening mechanisms to ensure load stability and prevent cargo shifting.

The global packaging straps and buckles market is projected to grow due to increasing global trade volume and logistics expansion, rising adoption of automated packaging systems, and growing demand for secure cargo transportation solutions.

According to a study, the global packaging straps and buckles market size was worth around USD 6.59 billion in 2024 and is predicted to grow to around USD 10.83 billion by 2034.

The CAGR value of the packaging straps and buckles market is expected to be around 5.10% during 2025-2034.

Which region will contribute notably to the market value of the packaging straps and buckles market?

North America is expected to lead the global packaging straps and buckles market during the forecast period.

The major players profiled in the global packaging straps and buckles market include Signode Industrial Group, Polychem Corporation, Teufelberger Holding AG, Mosca Direct, Cordstrap BV, Dynaric Inc., Samuel Strapping Systems, Scientex Berhad, Lifco AB, Titan Umreifungstechnik, Cyklop International, Linder GmbH, Baosteel Packaging, Strapack Corporation, and Auto Strap India Limited.

The report examines key aspects of the packaging straps and buckles market, including a detailed analysis of existing growth factors and restraints, as well as an examination of future growth opportunities and challenges that will impact the market.

The growth of the packaging straps and buckles market is impacted by environmental and regulatory factors such as transportation safety requirements, workplace safety standards, sustainable material regulations, and environmental protection policies promoting recyclable and reusable cargo securing alternatives.

Leading players in the packaging straps and buckles market are adopting comprehensive strategies focusing on automation innovation, sustainable materials, global expansion, partnerships, and circular economy practices.

Significant opportunities existing in the packaging straps and buckles market include collaborations with logistics providers, equipment manufacturers, recycling firms, e-commerce platforms, and investments in smart tracking and sustainable material technologies.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed