Global Mechanical Face Seals Market Size, Share, Growth Analysis Report - Forecast 2034

Mechanical Face Seals Market By Type (Balanced and Unbalanced Seals, Pusher and Non-pusher, Cartridge Seals, Conventional Seals, Others), By Application (Tracked Vehicles, Conveyor Systems, Heavy Trucks, Axles, Tunnel Boring Machines, Agriculture Machines, Mining Machines), and By Region: Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 4.27 Billion | USD 6.69 Billion | 4.3% | 2024 |

Mechanical Face Seals Market: Industry Perspective

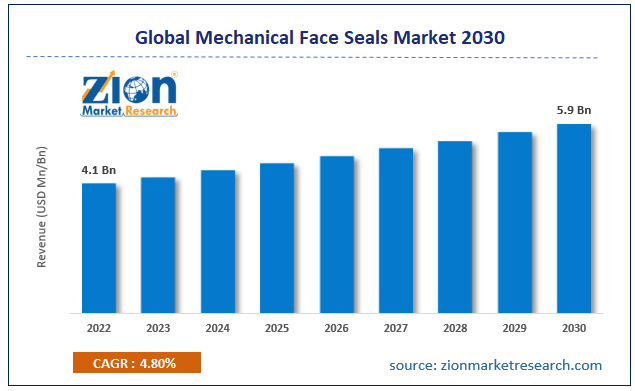

The global mechanical face seals market size was worth around USD 4.27 Billion in 2024 and is predicted to grow to around USD 6.69 Billion by 2034 with a compound annual growth rate (CAGR) of roughly 4.3% between 2025 and 2034. The report analyzes the global mechanical face seals market's drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the mechanical face seals industry.

Mechanical Face Seals Market: Overview

Mechanical face seals—also referred to as toric seals, dual cone seals, floating seals, and heavy-duty seals—are created especially to function in conditions with a lot of outside contamination, such as mud, sand, dirt, and water. In many different pieces of machinery, including pumps, compressors, and mixers, as well as in other settings where downtime would be particularly expensive and conventional sealing solutions lack the necessary durability, such as the oil and gas industry, the robust simplicity of mechanical face seals can be packaged neatly.

Key Insights

- As per the analysis shared by our research analyst, the global mechanical face seals market is estimated to grow annually at a CAGR of around 4.3% over the forecast period (2025-2034).

- Regarding revenue, the global mechanical face seals market size was valued at around USD 4.27 Billion in 2024 and is projected to reach USD 6.69 Billion by 2034.

- The mechanical face seals market is projected to grow at a significant rate due to rising demand for efficient leakage control in various industries, increasing industrialization, stringent environmental regulations, and advancements in seal design and materials for enhanced durability and performance.

- Based on Type, the Balanced and Unbalanced Seals segment is expected to lead the global market.

- On the basis of Application, the Tracked Vehicles segment is growing at a high rate and will continue to dominate the global market.

- Based on region, North America is predicted to dominate the global market during the forecast period.

Mechanical Face Seals Market: Dynamics

Key Growth Drivers:

Mechanical face seals market growth is driven by expanding demand across oil & gas, chemical processing, power generation, water treatment, and automotive sectors where reliable sealing under high pressure and harsh environments is critical. Advances in materials science — including silicon carbide, carbon, and advanced elastomers — and precision manufacturing techniques have improved seal performance and lifespan, encouraging broader adoption. Increasing emphasis on operational uptime and leak prevention to reduce environmental incidents and maintenance costs motivates end-users to invest in high-quality mechanical face seals. Growth is also supported by rising industrialization in emerging economies and the trend toward rotating equipment modernization and retrofits in mature markets.

Restraints:

High initial costs for premium mechanical face seals and the specialized equipment needed for installation and maintenance can deter smaller operators and slow replacement cycles. Volatility in raw material prices (ceramics, specialty metals, elastomers) raises manufacturing costs and compresses margins. Complex qualification and testing requirements for critical applications — for example subsea or high-temperature services — lengthen sales cycles and increase time-to-revenue for new products. Fragmented end-user demand and price competition from lower-cost generic alternatives also restrain market expansion.

Opportunities:

Significant opportunities exist in subsea oil & gas, renewable energy (wind turbines and hydro), and the growing chemical and pharmaceutical industries that require hygienic, high-integrity seals. Development of modular, cartridge-style seal systems simplifies installation and reduces downtime, opening aftermarket and retrofit markets. Innovations such as coatings for extreme wear resistance, hybrid material faces, sensor-embedded “smart” seals for predictive maintenance, and additive manufacturing for rapid prototyping create new value propositions for manufacturers. Expanding service contracts, inspection, and condition-based maintenance offerings also present recurring-revenue opportunities.

Challenges:

Key challenges include ensuring long-term reliability in extreme operating conditions (abrasion, thermal cycling, corrosive media) where seal failure risks safety incidents and costly shutdowns. Supply-chain disruptions and lead-time pressures for specialty materials can delay deliveries and upgrades. Tightening environmental and industry regulations increase compliance complexity for both producers and end users, while the need for highly skilled technicians to select, install, and maintain mechanical face seals limits rapid adoption in some regions. Finally, balancing cost, performance, and customization requirements across diverse applications remains an ongoing engineering and commercial challenge.

Mechanical Face Seals Market: Segmentation

The global Mechanical Face Seals industry is segmented based on type, application, and region. All the segments have been analyzed based on present and future trends and the market is estimated from 2025 to 2034.

Based on the type, the global market is bifurcated into Balanced & Unbalanced Seals, Pusher & Non-pusher, Cartridge Seals, Conventional Seals, and Others. The cartridge seals segment is expected to hold a significant market share over the forecast period. Pumps, mixers, and rotating machinery all require many types of mechanical face seals, but one particular kind is known as a cartridge seal. Compared to conventional component seals, they provide several benefits, including ease of installation and low maintenance needs. These benefits of cartridge seals propel the segment expansion.

Based on the application, the global Mechanical Face Seals industry is bifurcated into tracked vehicles, conveyor systems, heavy trucks, axles, tunnel boring machines, agriculture machines, and mining machines. The tracked vehicles segment is expected to grow at the highest CAGR over the forecast period. When it comes to the efficiency and dependability of tracked vehicles, which are frequently employed in mining, agricultural, construction, and military applications, mechanical face seals are essential. These seals are crucial parts for shielding the tracked vehicles' undercarriage and other vital components from pollution, water intrusion, and abrasive particles. In addition, the growing mining industry is also propelling the segment growth. For instance, according to the data given by Federal Reserves, in August 2023, mining production in the US climbed 3.87 percent over the corresponding month the year before. Thus, this is expected to propel the market growth over the forecast period.

The Regional, this segment includes the current and forecast demand for North America, Europe, Asia Pacific, Latin America,and the Middle East and Africa.

Mechanical Face Seals Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Mechanical Face Seals Market |

| Market Size in 2024 | USD 4.27 Billion |

| Market Forecast in 2034 | USD 6.69 Billion |

| Growth Rate | CAGR of 4.3% |

| Number of Pages | 205 |

| Key Companies Covered | Trelleborg Group, SAP PARTS Pvt. Ltd, ROC Carbon Company, EKK, Grizzly Supplies, Engineered Seal Products, NOK CORPORATION, Beston Seals, FTL/IDEX, Senaa Engineering, Micro Seals India, Meccanotecnica Umbra S.p.A., Tenneco Inc., John Crane, Stein Seal, Technetics Group and Vulcan Engineering Limited, and others. |

| Segments Covered | By Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2020 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Mechanical Face Seals Market: Regional Analysis

The Asia Pacific is expected to dominate the global mechanical face seal market over the forecast period. A center for quick industrialization and economic expansion has been the Asia-Pacific region. Heavy machinery, construction equipment, and mining equipment—important industries that largely rely on mechanical face seals—have seen increasing demand as a result of the significant economic expansion that has taken place in nations like China and India. Moreover, the region is undergoing major infrastructure development, including road, bridge, airport, and urban development projects.

Due to the construction expansion, there is a high need for heavy machinery with mechanical face seals to assure equipment durability and minimize downtime. For instance, according to the data given by Invest India, more than 40% of the population is predicted to dwell in urban India by 2030 (up from 33% presently), creating a demand for 25 million extra mid-range and affordable homes. Under NIP, India has a $1.4 trillion infrastructure investment budget, with 24% going to renewable energy, 18% going to roads and highways, 17% going to urban infrastructure, and 12% going to railroads. Thus, the aforementioned stats are expected to propel the market growth in the region.

Mechanical Face Seals Market: Competitive Analysis

The report provides a company market share analysis to give a broader overview of the key market players. In addition, the report also covers key strategic developments of the market, including acquisitions & mergers, new product launches, agreements, partnerships, collaborations & joint ventures, research & development, and regional expansion of major participants involved in the mechanical face seals market on a global and regional basis.

The global Mechanical Face Seals market is dominated by players like:

- Trelleborg Group

- SAP PARTS Pvt. Ltd

- ROC Carbon Company

- EKK

- Grizzly Supplies

- Engineered Seal Products

- NOK CORPORATION

- Beston Seals

- FTL/IDEX

- Senaa Engineering

- Micro Seals India

- Meccanotecnica Umbra S.p.A.

- Tenneco Inc.

- John Crane

- Stein Seal

- Technetics Group and Vulcan Engineering Limited

The global Mechanical Face Seals market is segmented as follows:

By Type

- Balanced and Unbalanced Seals

- Pusher and Non-pusher

- Cartridge Seals

- Conventional Seals

- Others

By Application

- Tracked Vehicles

- Conveyor Systems

- Heavy Trucks

- Axles

- Tunnel Boring Machines

- Agriculture Machines

- Mining Machines

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Mechanical face seals—also referred to as toric seals, dual cone seals, floating seals, and heavy-duty seals—are created especially to function in conditions with a lot of outside contamination, such as mud, sand, dirt, and water. In many different pieces of machinery, including pumps, compressors, and mixers, as well as in other settings where downtime would be particularly expensive and conventional sealing solutions lack the necessary durability, such as the oil and gas industry, the robust simplicity of mechanical face seals can be packaged neatly.

The global mechanical face seals market is expected to grow due to increasing industrial automation, demand for leak-proof sealing solutions, growth in oil & gas and chemical industries, and advancements in material technology.

According to a study, the global mechanical face seals market size was worth around USD 4.27 Billion in 2024 and is expected to reach USD 6.69 Billion by 2034.

The global mechanical face seals market is expected to grow at a CAGR of 4.3% during the forecast period.

North America is expected to dominate the mechanical face seals market over the forecast period.

Leading players in the global mechanical face seals market include Trelleborg Group, SAP PARTS Pvt. Ltd, ROC Carbon Company, EKK, Grizzly Supplies, Engineered Seal Products, NOK CORPORATION, Beston Seals, FTL/IDEX, Senaa Engineering, Micro Seals India, Meccanotecnica Umbra S.p.A., Tenneco Inc., John Crane, Stein Seal, Technetics Group and Vulcan Engineering Limited, among others.

The report explores crucial aspects of the mechanical face seals market, including a detailed discussion of existing growth factors and restraints, while also examining future growth opportunities and challenges that impact the market.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed