Glass Drilling Machine Market Size, Share, Trends, Growth 2034

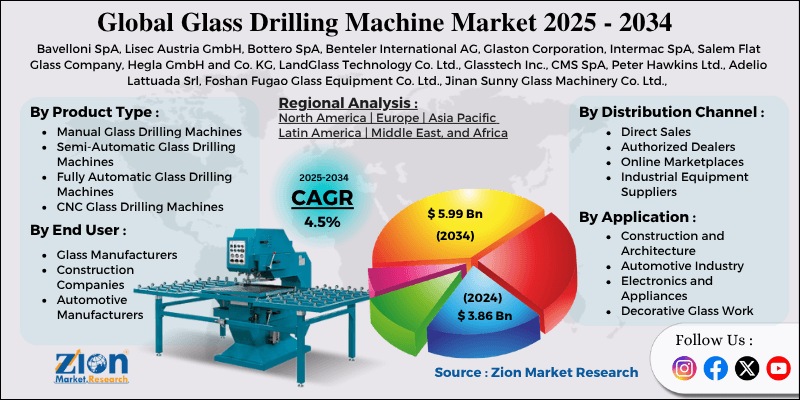

Glass Drilling Machine Market By Product Type (Manual Glass Drilling Machines, Semi-Automatic Glass Drilling Machines, Fully Automatic Glass Drilling Machines, and CNC Glass Drilling Machines), By Application (Construction and Architecture, Automotive Industry, Electronics and Appliances, and Decorative Glass Work), By Distribution Channel (Direct Sales, Authorized Dealers, Online Marketplaces, and Industrial Equipment Suppliers), By End-User (Glass Manufacturers, Construction Companies, Automotive Manufacturers, and Small Scale Fabricators), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

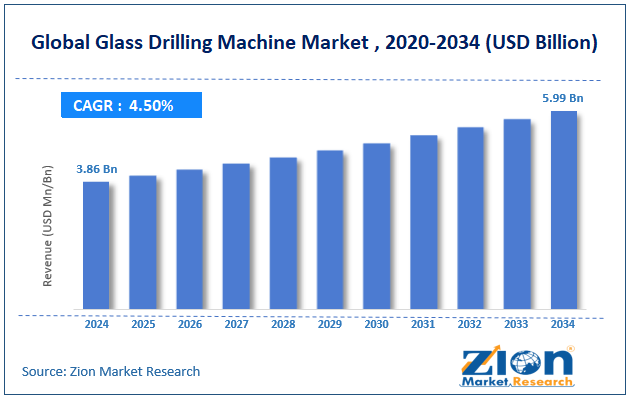

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 3.86 Billion | USD 5.99 Billion | 4.50% | 2024 |

Glass Drilling Machine Industry Perspective:

The global glass drilling machine market was valued at approximately USD 3.86 billion in 2024 and is expected to reach around USD 5.99 billion by 2034, growing at a compound annual growth rate (CAGR) of roughly 4.5% between 2025 and 2034.

Glass Drilling Machine Market: Overview

Glass drilling machines are industrial machines that create precise holes and openings in glass materials without cracking or shattering. They use diamond-tipped drill bits, cooling systems, and controlled drilling parameters to make clean and accurate holes in tempered glass, laminated glass, and other glass products.

The glass drilling machine market serves the construction and architecture industries for window installations, the automotive industry for windshields and windows, the electronics industry for display screens and covers, and the decorative industry for artistic glass work. Advanced models feature computer numerical control, auto-feed, and precision positioning to ensure high-quality and efficient production.

The growing demand for energy-efficient buildings and increasing automotive glass applications are expected to drive significant growth in the global glass drilling machine industry over the forecast period.

Key Insights:

- As per the analysis shared by our research analyst, the global glass drilling machine market is estimated to grow annually at a CAGR of around 4.5% over the forecast period (2025-2034)

- In terms of revenue, the global glass drilling machine market size was valued at around USD 3.86 billion in 2024 and is projected to reach USD 5.99 billion by 2034.

- The glass drilling machine market is projected to grow significantly due to the increasing demand from construction industries, expansion of automotive glass applications, and rising adoption of automated manufacturing processes in glass processing facilities.

- Based on product type, fully automatic glass drilling machines lead the segment and are expected to continue dominating the global market.

- Based on the application, construction and architecture are expected to lead the market.

- Based on the distribution channel, direct sales are anticipated to command the largest market share.

- Based on end-users, glass manufacturers are expected to lead the market during the forecast period.

- Based on region, Asia Pacific is projected to lead the global market during the forecast period.

Glass Drilling Machine Market: Growth Drivers

Increasing construction activities and architectural glass applications

The glass drilling machine market is growing rapidly due to the increasing number of construction projects worldwide and the growing use of glass in modern architecture, which requires precise drilling for mounting systems and hardware installation.

Modern buildings focus on natural light and visual connectivity, so there is a lot of use for curtain walls, glass facades, and large window systems that need hole drilling for structural connections and hardware mounting.

Green building initiatives promote energy-efficient glazing systems that often require specialized drilling for ventilation components, sensors, and control systems.

Automotive industry growth and advanced glass technology adoption

The glass drilling machine industry benefits from the expanding automotive sector and the increasing complexity of vehicle glass systems, which require precise manufacturing processes.

Modern vehicles feature advanced driver assistance systems, heads-up displays, and integrated electronics that necessitate precise hole drilling in windshields and side windows for sensor mounting and wire routing. Electric vehicle production is driving demand for specialized glass components with unique drilling requirements for charging ports, cooling systems, and battery monitoring equipment.

Luxury and premium vehicles use complex glass features, like heated windows, embedded antennas, and smart glass technology, which need precision drilling.

Glass Drilling Machine Market: Restraints

High initial investment costs and technical complexity

Despite the growing market, the glass drilling machine market faces challenges, including high capital investment and technical expertise required for the operation and maintenance of sophisticated drilling equipment. Advanced CNC glass drilling machines are expensive and are a barrier for small and medium-sized glass processing companies with limited capital.

Precision glass drilling requires specific environmental conditions like temperature control, vibration isolation, and a dust-free environment, which may require additional facility investment. Tool wear and replacement costs of diamond drilling bits and other consumables can be high, especially for high-volume production.

Glass Drilling Machine Market: Opportunities

Industrial automation and Industry 4.0 integration

The glass drilling machine market is opening up opportunities through the integration of automation and Industry 4.0 principles, which aim to increase productivity, quality control, and operational efficiency in glass processing.

Smart manufacturing is driving demand for connected drilling machines that give real-time production data, predictive maintenance, and remote monitoring. AI and machine learning are enabling adaptive drilling parameters based on glass type, thickness, and environmental conditions.

Robotic integration enables the automated loading, positioning, and unloading of glass panels, reducing labor costs and improving production consistency. Quality control systems equipped with computer vision and sensor technology can detect drilling defects in real time and adjust parameters to maintain quality standards.

Glass Drilling Machine Market: Challenges

Material handling complexity and safety requirements

The glass drilling machine market faces many challenges, including the handling of fragile glass and strict safety regulations in industrial environments. Glass handling systems must prevent cracking, chipping, and breakage during drilling and maintain precise positioning and alignment for accurate hole placement.

Safety regulations require full protection for operators, including emergency stops, safety barriers, and dust collection systems, to prevent injury from glass fragments and silica dust exposure.

Different types of glass (tempered, laminated, and specialty coatings) require different drilling parameters and handling procedures, which add to machine operation and setup complexity.

Glass Drilling Machine Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Glass Drilling Machine Market |

| Market Size in 2024 | USD 3.86 Billion |

| Market Forecast in 2034 | USD 5.99 Billion |

| Growth Rate | CAGR of 4.5% |

| Number of Pages | 212 |

| Key Companies Covered | Bavelloni SpA, Lisec Austria GmbH, Bottero SpA, Benteler International AG, Glaston Corporation, Intermac SpA, Salem Flat Glass Company, Hegla GmbH and Co. KG, LandGlass Technology Co. Ltd., Glasstech Inc., CMS SpA, Peter Hawkins Ltd., Adelio Lattuada Srl, Foshan Fugao Glass Equipment Co. Ltd., Jinan Sunny Glass Machinery Co. Ltd., Shenzhen Handong Glass Machinery Co. Ltd., Beijing Pujinli Technology Co. Ltd., Guangdong ENKONGS Machinery Co. Ltd., Forel SpA, Turomas Technological Solutions SL., and others. |

| Segments Covered | By Product Type, By Application, By Distribution Channel, By End User, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Glass Drilling Machine Market: Segmentation

The global glass drilling machine market is segmented into product type, application, distribution channel, end-user, and region.

Based on product type, the market is segregated into manual glass drilling machines, semi-automatic glass drilling machines, fully automatic glass drilling machines, and CNC glass drilling machines. Fully automatic glass drilling machines lead the market due to their superior productivity, consistent quality output, and reduced labor requirements for high-volume production operations.

Based on application, the glass drilling machine industry is classified into construction and architecture, the automotive industry, electronics and appliances, and decorative glass work. Construction and architecture hold the largest market share due to the extensive use of glass in modern building designs, infrastructure development projects, and the growing demand for energy-efficient glazing systems.

Based on the distribution channel, the glass drilling machine market is divided into direct sales, authorized dealers, online marketplaces, and industrial equipment suppliers. Direct sales are expected to lead the market during the forecast period, driven by high-value equipment purchases, customization requirements, and the need for technical support from manufacturers.

Based on the end-user, the market is segmented into glass manufacturers, construction companies, automotive manufacturers, and small-scale fabricators. Glass manufacturers lead the market share due to their high-volume production requirements, diverse application needs, and the continuous operation of glass drilling equipment in manufacturing facilities.

Glass Drilling Machine Market: Regional Analysis

Asia Pacific to lead the market

The Asia Pacific leads the global glass drilling machine market due to rapid industrialization, massive construction activities, and the presence of major glass manufacturing hubs in countries such as China, India, Japan, and South Korea. The region accounts for around 45% of the global market share, with China being the largest producer and consumer of glass drilling machines.

The construction growth in emerging Asian economies is driving sustained demand for glass processing equipment as new infrastructure projects incorporate modern glazing systems. Automotive manufacturing centers in the region require specialized glass drilling for vehicle production, and there is consistent demand for advanced drilling machines.

Electronics manufacturing in countries such as South Korea, Taiwan, and China utilizes precision glass drilling for display screens, protective covers, and electronic device components.

Europe is expected to show steady growth.

Europe is experiencing steady growth in the glass drilling machine industry, driven by advanced manufacturing capabilities, high-quality standards, and innovation in glass processing technologies in established industrial hubs. The region’s focus on energy efficiency and sustainable building practices is driving demand for high-end glazing systems that require precision drilling.

Leadership in the automotive industry in countries such as Germany, France, and Italy is driving the adoption of advanced glass drilling machines for vehicle manufacturing applications.

Architectural glass applications in commercial and residential construction projects are maintaining a steady demand for drilling machines in European markets. Research and development in glass processing technologies are supporting the innovation and development of next-generation drilling machines with more capabilities.

Recent Market Developments:

- In April 2025, Precision Glass Technologies introduced an advanced CNC glass drilling system featuring AI-powered parameter optimization and real-time quality monitoring capabilities for high-precision applications.

- In February 2025, European Glass Equipment launched a new series of environmentally friendly glass drilling machines with reduced energy consumption and advanced dust collection systems for improved workplace safety.

Glass Drilling Machine Market: Competitive Analysis

The global glass drilling machine market is led by players like:

- Bavelloni SpA

- Lisec Austria GmbH

- Bottero SpA

- Benteler International AG

- Glaston Corporation

- Intermac SpA

- Salem Flat Glass Company

- Hegla GmbH and Co. KG

- LandGlass Technology Co. Ltd.

- Glasstech Inc.

- CMS SpA

- Peter Hawkins Ltd.

- Adelio Lattuada Srl

- Foshan Fugao Glass Equipment Co. Ltd.

- Jinan Sunny Glass Machinery Co. Ltd.

- Shenzhen Handong Glass Machinery Co. Ltd.

- Beijing Pujinli Technology Co. Ltd.

- Guangdong ENKONGS Machinery Co. Ltd.

- Forel SpA

- Turomas Technological Solutions SL.

The global Glass Drilling Machine market is segmented as follows:

By Product Type

- Manual Glass Drilling Machines

- Semi-Automatic Glass Drilling Machines

- Fully Automatic Glass Drilling Machines

- CNC Glass Drilling Machines

By Application

- Construction and Architecture

- Automotive Industry

- Electronics and Appliances

- Decorative Glass Work

By Distribution Channel

- Direct Sales

- Authorized Dealers

- Online Marketplaces

- Industrial Equipment Suppliers

By End User

- Glass Manufacturers

- Construction Companies

- Automotive Manufacturers

- Small Scale Fabricators

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Glass drilling machines are industrial machines that create precise holes and openings in glass materials without cracking or shattering.

The glass drilling machine market is expected to be driven by increasing construction activities and architectural glass applications, the growth of the automotive industry with advanced glass technologies, the rising adoption of automation in manufacturing processes, and the growing demand for precision glass processing in electronics applications.

According to our study, the global glass drilling machine market was worth around USD 3.86 billion in 2024 and is predicted to grow to around USD 5.99 billion by 2034.

The CAGR value of the glass drilling machine market is expected to be around 4.5% during 2025-2034.

The global glass drilling machine market will register the highest revenue contribution from Asia Pacific during the forecast period.

Key players in the glass drilling machine market include Bavelloni SpA, Lisec Austria GmbH, Bottero SpA, Benteler International AG, Glaston Corporation, Intermac SpA, Salem Flat Glass Company, Hegla GmbH, and Co. KG, LandGlass Technology Co. Ltd., Glasstech Inc., CMS SpA, Peter Hawkins Ltd., Adelio Lattuada Srl, Foshan Fugao Glass Equipment Co. Ltd., Jinan Sunny Glass Machinery Co. Ltd., Shenzhen Handong Glass Machinery Co. Ltd., Beijing Pujinli Technology Co. Ltd., Guangdong ENKONGS Machinery Co. Ltd., Forel SpA, and Turomas Technological Solutions SL.

The report provides a comprehensive analysis of the glass drilling machine market, including an in-depth examination of market drivers, restraints, emerging trends, regional dynamics, and future growth prospects. It also examines the competitive dynamics, technological innovations, distribution strategies, and industrial applications that shape the glass processing equipment market ecosystem.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed