Cross-Belt Analyzers Market Size, Share, Trends Forecast 2034

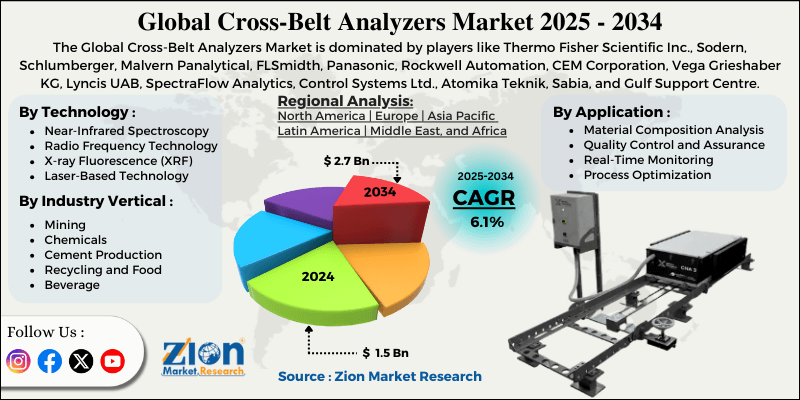

Cross-Belt Analyzers Market By Technology (Near-Infrared Spectroscopy (NIR), Radio Frequency (RF) Technology, X-ray Fluorescence (XRF), and Laser-Based Technology), By Application (Material Composition Analysis, Quality Control and Assurance, Real-Time Monitoring, and Process Optimization), By Industry Vertical (Mining, Chemicals, Cement Production, Recycling, and Food and Beverage), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

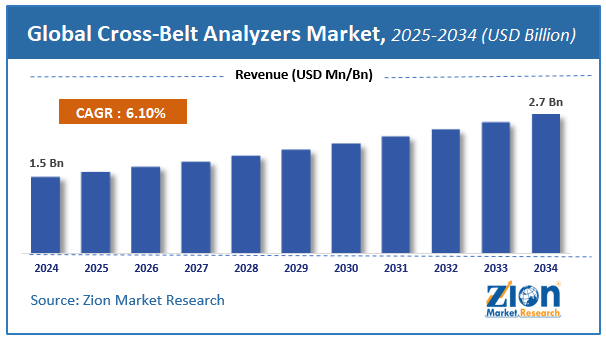

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 1.5 Billion | USD 2.7 Billion | 6.1% | 2024 |

Cross-Belt Analyzers Industry Prospective:

The global cross-belt analyzer market size was worth around USD 1.5 billion in 2024 and is predicted to grow to around USD 2.7 billion by 2034, with a compound annual growth rate (CAGR) of roughly 6.1% between 2025 and 2034.

Key Insights

- As per the analysis shared by our research analyst, the global cross-belt analyzer market is estimated to grow annually at a CAGR of around 6.1% over the forecast period (2025-2034).

- In terms of revenue, the global cross-belt analyzers market size was valued at around USD 1.5 billion in 2024 and is projected to reach USD 2.7 billion by 2034.

- Adoption of automation, Industry 4.0 & smart technologies is expected to drive the cross-belt analyzers market over the forecast period.

- Based on the technology, the Radio Frequency (RF) Technology segment is expected to dominate the market over the projected period.

- Based on the application, the quality control and assurance segment is expected to capture the largest market share over the projected period.

- Based on the industry vertical, the mining segment is expected to capture the largest market share over the projected period.

- Based on region, the Asia Pacific is expected to dominate the market during the forecast period.

Cross-Belt Analyzers Market: Overview

Cross-belt analyzers are high-tech equipment that monitor items above conveyor belts. They provide constant, up-to-date information on the chemical or elemental makeup of bulk materials as they undergo industrial processes. These analyzers can identify the materials present without stopping the flow or requiring a human sample. They use technologies such as prompt gamma neutron activation analysis (PGNAA), pulsed fast thermal neutron activation (PFTNA), and X-ray-based methods. In the cement, mining, coal, metals, and bulk materials-handling industries, cross-belt analyzers are very frequent. They support quality control, improve process efficiency, reduce material variation, and ensure compliance with all applicable government regulations.

They provide rapid, accurate information across the entire material stream, helping users make decisions more quickly, reduce costs, and maintain a more consistent quality of the end product. The main driver of the cross-belt analyzer market is the growing need for real-time, ongoing material examination across industries such as cement, mining, coal, metals, and bulk material processing. Cross-belt analyzers are increasingly used by manufacturers because they provide real-time, representative data without interrupting material flow. This helps improve process control, product quality, and operational efficiency. The market is rising because there is more focus on cutting costs and reducing waste. Real-time composition monitoring optimizes the use of raw materials and reduces rework.

Cross-Belt Analyzers Market Dynamics

Growth Drivers

How does the increasing demand for real-time material analysis propel the cross-belt analyzer industry growth?

The growing need for real-time material analysis is driving industry growth by letting manufacturers make quick, data-driven decisions that improve efficiency, quality, and cost control at every stage of the production process. Real-time analysis lets companies monitor the composition and properties of materials as they move through processes. This reduces the time required for typical lab tests and the risk of producing results that aren't up to standard. This rapid input enables the integration of raw materials, maintains process conditions, reduces waste, and lowers costs by avoiding rework or downtime. Industries like mining, cement, metals, and bulk material processing are under increasing pressure to be more efficient, maintain high product quality, and comply with stricter environmental and quality standards. Because of this, it is very important to obtain accurate, continuous data. The need for real-time material insights is expanding, driving greater use of advanced analytical technologies and overall growth in the sector.

Restraints

High initial costs & capital investment are impeding the industry growth

High start-up costs and capital expenditures make it difficult for small and medium-sized enterprises to enter the market, slowing sector growth. Advanced analytical systems require high up-front costs to purchase, install, integrate, and start up, which can strain capital budgets and lengthen payback periods. Businesses have to pay for more than just the hardware. They also have to pay for software, training, and ongoing technical support, all of which add to the total cost of ownership. These high upfront costs deter decision-makers, leading them to either delay adoption or opt for traditional, lower-cost options, such as routine laboratory tests. This is especially true for firms that are sensitive to price or have thin margins. So, even while current analysis solutions offer long-term benefits in terms of quality and efficiency, the high cost of capital spending makes it hard for them to enter the market and slows the industry's overall expansion.

Opportunities

Will technological advancements offer a potential opportunity for the cross-belt analyzer industry’s growth?

Technological advancement will create significant opportunities for industrial growth by making analytical systems more efficient, accurate, and easier to use. Real-time measurements are becoming more accurate due to ongoing developments in sensor technology, detecting methods, and software analytics. This reduces mistakes and downtime. AI, machine learning, and advanced data analytics work together to make process control smarter, maintenance more predictable, and decision-making faster. This makes these systems more helpful to end users as a whole. New innovations that extend system lifespans, simplify calibration, and enable integration with automation and Industry 4.0 platforms reduce the total cost of ownership and make operations easier to understand. These advances make it easier for more industries to adopt them, especially in cost-sensitive and emerging regions, helping the cross-belt analyzers industry.

Challenges

How do maintenance & calibration requirements pose a major challenge to the cross-belt analyzer market expansion?

The need for maintenance and calibration is a major obstacle to market growth, as it complicates operations, increases costs, and causes downtime for end users. To ensure measurements are accurate, advanced analytical systems must be regularly calibrated. This is especially important when operating in harsh industrial environments characterized by dust, vibration, temperature fluctuations, and moisture. These regular calibrations sometimes require experienced experts, specialized tools, and planned process interruptions, which can slow production and reduce overall efficiency. Also, regular maintenance to prevent sensor drift, parts failures, or system failures raises the total cost of ownership over the life of the equipment. In cost-sensitive industries and in facilities with limited technical expertise, these ongoing needs may be more important than the perceived benefits. This can lead to ambiguity or delayed adoption, slowing cross-belt analyzer market growth.

Cross-Belt Analyzers Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Cross-Belt Analyzers Market |

| Market Size in 2024 | USD 1.5 Billion |

| Market Forecast in 2034 | USD 2.7 Billion |

| Growth Rate | CAGR of 6.1% |

| Number of Pages | 280 |

| Key Companies Covered | Thermo Fisher Scientific Inc., Sodern, Schlumberger, Malvern Panalytical, FLSmidth, Panasonic, Rockwell Automation, CEM Corporation, Vega Grieshaber KG, Lyncis UAB, SpectraFlow Analytics, Control Systems Ltd., Atomika Teknik, Sabia, and Gulf Support Centre, among others. |

| Segments Covered | By Technology, By Application, By Industry Vertical and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America,The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Cross-Belt Analyzers Market: Segmentation

Technology Insights

The Radio Frequency (RF) Technology segment is expected to dominate the market. Cross-belt analyzers that use Radio Frequency (RF) technology could significantly increase market revenue growth by enabling faster, more effective testing of materials. RF-based sensing approaches let analyzers find and describe materials without touching them. These methods are typically employed with near-infrared (NIR), X-ray fluorescence (XRF), and neutron activation. This speeds things up and makes it easier to decide what to do right away.

RF technology can enhance system reliability in challenging industrial applications by facilitating the passage of bulk material streams, reducing sensitivity to external noise, and simplifying calibration. Mining, cement production, coal processing, and recycling are some of the industries that need online compositional analysis that is faster, more precise, and less expensive. RF-enabled cross-belt analyzers can be used in more ways and attract more consumers, which means that producers will sell more of them and make higher profits.

Application Insights

The quality control and assurance segment is expected to hold the largest revenue share over the projected period because it deals with important operational issues in firms that depend on consistent material properties and processing speed. Cross-belt analyzers provide firms with continuous, real-time information on the composition of their raw materials or production streams. This lets them immediately identify differences and take action before producing items that don't meet specifications. This ability reduces waste and rework, ensuring that items always meet high-quality standards and regulatory criteria. This is especially significant in industries like cement, mining, coal, metals, and bulk material handling.

Industry Vertical Insights

The mining segment is expected to hold the largest revenue share over the projected period. The growth is being driven by the industry's need for accurate, real-time material characterization during extraction and processing. In mining, the grade and composition of the ore directly affect the efficiency of processing, the amount recovered, the energy required, and the overall profitability of the operation. Cross-belt analyzers let operators continuously monitor material flow on conveyor belts. They may find changes in mineral composition, adjustments to process settings, improved blending procedures, and reduced waste. Mining companies seeking to maximize resource utilization and gain a competitive advantage should invest in analyzers, as they enable real-time control, leading to improved resource utilization, lower operational costs, and superior product quality.

Cross-Belt Analyzers Market: Regional Analysis

The Asia Pacific is expected to dominate the cross-belt analyzer market growth with a revenue share of 35% in 2024. The cross-belt analyzer market in the Asia Pacific region is growing due to rapid industrialization, the rise of core industries, and the increasing adoption of real-time material analysis technology. There is a growing need for improved process control and quality assurance systems in the mining, cement, steel, and power-generating industries of China, India, Japan, and Southeast Asia. This is because these industries are growing quickly and need to be more efficient and consistent. Real-time analyzers help operators use as much raw material as possible, reduce waste, and maintain high product quality.

This is especially useful when production levels rise. The growing emphasis on digital transformation and industrial automation, including integration with Industry 4.0 systems and advanced analytics, is driving the adoption of sophisticated analyzer solutions across the manufacturing and extraction sectors. Cross-belt analyzers are becoming more popular in the Asia Pacific, one of the regions expanding the fastest for them. This is due to strong government policies, infrastructure investments, and stricter quality and environmental standards.

Cross-Belt Analyzers Market: Competitive Analysis

The global cross-belt analyzers market is dominated by players like-

- Thermo Fisher Scientific Inc.

- Sodern

- Schlumberger

- Malvern Panalytical

- FLSmidth

- Panasonic

- Rockwell Automation

- CEM Corporation

- Vega Grieshaber KG

- Lyncis UAB

- SpectraFlow Analytics

- Control Systems Ltd.

- Atomika Teknik

- Sabia

- Gulf Support Centre

The global cross-belt analyzers market is segmented as follows:

By Technology

- Near-Infrared Spectroscopy (NIR)

- Radio Frequency (RF) Technology

- X-ray Fluorescence (XRF)

- Laser-Based Technology

By Application

- Material Composition Analysis

- Quality Control and Assurance

- Real-Time Monitoring

- Process Optimization

By Industry Vertical

- Mining

- Chemicals

- Cement Production

- Recycling and Food

- Beverage

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed