Bevel Gearbox Market Size, Share, Value, Industry Trends 2034

Bevel Gearbox Market By Gear Type (Straight Bevel Gears, Spiral Bevel Gears, Zerol Bevel Gears, Hypoid Bevel Gears, Miter Gears, and Others), By Application (Automotive, Industrial Machinery, Aerospace, Construction Equipment, Marine, Power Generation), By Material (Steel, Cast Iron, Aluminum Alloy, Bronze, Composite Materials), By Configuration (Right Angle, Horizontal, Vertical, Custom Configurations), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

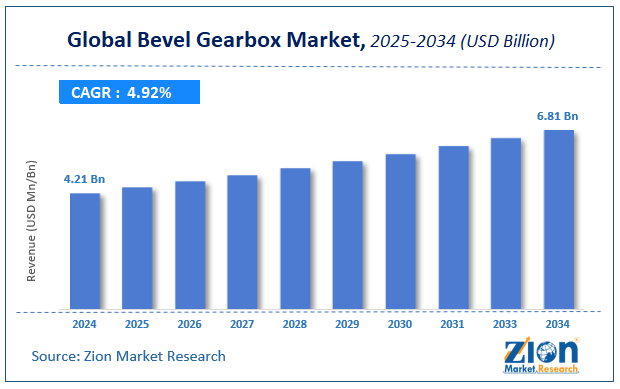

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 4.21 Billion | USD 6.81 Billion | 4.92% | 2024 |

Bevel Gearbox Industry Prospective

The global bevel gearbox market size was worth approximately USD 4.21 billion in 2024 and is projected to grow to around USD 6.81 billion by 2034, with a compound annual growth rate (CAGR) of roughly 4.92% between 2025 and 2034.

Key Insights

- As per the analysis shared by our research analyst, the global bevel gearbox market is estimated to grow annually at a CAGR of around 4.92% over the forecast period (2025-2034).

- In terms of revenue, the global bevel gearbox market size was valued at approximately USD 4.21 billion in 2024 and is projected to reach USD 6.81 billion by 2034.

- The bevel gearbox market is projected to grow significantly due to increasing industrial automation, expansion of construction and mining activities, growth in renewable energy installations, and rising automotive production worldwide.

- Based on gear type, the spiral bevel gears segment is expected to lead the bevel gearbox market, while the hypoid bevel gears segment is anticipated to experience significant growth.

- Based on application, the automotive segment is expected to lead the bevel gearbox market, while the power generation segment is anticipated to witness notable growth.

- Based on material, the steel segment is the dominating segment, while the aluminum alloy segment is projected to witness sizeable revenue over the forecast period.

- Based on the configuration, the right-angle segment is expected to lead the market compared to the custom configurations segment.

- Based on region, Asia Pacific is projected to dominate the global bevel gearbox market during the estimated period, followed by North America.

Bevel Gearbox Market: Overview

A bevel gearbox is a mechanical power transmission device designed to change the direction of rotation and transfer torque between intersecting shafts using cone-shaped gears. Bevel gearboxes help machines move power from one direction to another, such as from horizontal motion to vertical motion, making them essential in compact and complex equipment layouts. These gearboxes are widely used where space limits or design requirements need angled power flow. Precision manufacturing methods produce accurately shaped gear teeth, enabling smooth and efficient gear engagement at common angles such as 90 degrees. The automotive industry uses bevel gearboxes in differential systems to support smooth turning and reduce tire wear. Heavy equipment such as cranes, excavators, and mining machines depends on bevel gearboxes for lifting and motion control. Marine systems apply bevel gearboxes to connect engines with propeller shafts, while aerospace designs rely on lightweight versions for helicopter and aircraft controls. Manufacturing plants use bevel gearboxes in conveyors, packaging lines, and robotic systems. Agricultural machinery uses bevel gearboxes to drive mowers and harvesters.

Spiral bevel gears deliver quieter operation, higher load capacity, and better efficiency. Durable steel materials support heavy-duty use, while aluminum options reduce weight. Proper lubrication ensures long service life and reliable performance in demanding applications. The expanding industrial automation sector and increasing demand for efficient power transmission systems are expected to drive growth in the bevel gearbox market throughout the forecast period.

Bevel Gearbox Market Dynamics

Growth Drivers

How is industrial automation expansion driving demand for the bevel gearbox market?

The bevel gearbox market shows strong growth as manufacturing adopts automation requiring power transmission for robots and conveyor systems. Factory automation focuses on efficiency, lower labor costs, and better quality using precise motion control supported by reliable bevel gearboxes. Collaborative robots that work alongside human workers require compact, efficient gearboxes that power multiple joints and enable articulated movement within limited spaces. Automated guided vehicles in warehouses and factories use bevel gearboxes for steering, drive control, and accurate material transport operations. High-speed packaging machinery depends on bevel gearboxes for timing, directional motion changes, and synchronized operation across production stations.

Assembly line automation uses bevel gearboxes to transfer power from central motors to tools and fixtures positioned at various angles. Industry 4.0 and smart manufacturing trends increase demand for advanced machinery with motion control and bevel gearbox solutions. Automotive, electronics, food, beverage, pharmaceutical, and material handling sectors rely on bevel gearboxes for accuracy, hygiene, and continuous operation. Distribution centers employ bevel gearboxes in sortation systems, vertical lifts, and automated storage and retrieval equipment to facilitate efficient logistics flow.

Renewable energy sector expansion is creating new opportunities.

The global bevel gearbox market benefits from rapid growth in wind turbine installations and in solar tracking systems, driven by the need for reliable power transmission equipment. Wind turbines use large bevel gearboxes in yaw systems to rotate the nacelle toward the prevailing wind, improving efficiency and ensuring consistent, clean energy generation. Blade pitch control systems employ compact bevel gearboxes that adjust angles across varying wind speeds, supporting safe operation and optimal renewable power output. Offshore wind, hydroelectric, tidal, and geothermal projects demand durable bevel gearboxes resisting corrosion, heat, moisture, and continuous renewable energy operation. Energy storage facilities, including pumped hydro systems, use industrial bevel gearboxes to move water between reservoirs at different elevations efficiently. Global carbon-neutrality goals and renewable energy incentives drive investment, creating steady demand for bevel gearbox manufacturing and aftermarket replacement services.

Restraints

High manufacturing costs and complexity are limiting market accessibility

A major challenge for the bevel gearbox industry is the high manufacturing costs associated with complex production methods, specialized machinery, and skilled labor. Bevel gearbox manufacturing uses precise machining processes, including cutting, grinding, and lapping, to create accurate gear teeth for smooth, angled power transfer. Advanced CNC machines required for bevel gear production demand heavy capital investment, creating entry barriers for small gearbox manufacturers. Skilled gear machinists and inspectors remain limited as experienced workers retire and fewer people choose industrial manufacturing careers. Quality inspection requires advanced measurement tools, heat-treatment control, and careful assembly alignment, thereby increasing production costs and technical complexity. Custom bevel gearbox designs need engineering analysis, prototyping, and validation, which raises development cost for specialized industrial applications. High-grade steel material pricing, low production volumes, and import competition continue to pressure market profitability. Warranty risk and safety margins push manufacturers toward conservative designs, increasing cost within the global bevel gearbox market.

Opportunities

How is the electric vehicle revolution creating growth potential for the bevel gearbox industry?

The bevel gearbox industry gains a strong opportunity as the automotive sector shifts toward electric vehicles, needing advanced power transmission and torque control solutions. Electric vehicles employ various drivetrain layouts in which electric motors deliver instantaneous torque, necessitating bevel gearboxes designed for high load and wide-speed operation. Compact bevel gearboxes support motor placement near axles and wheel hubs while enabling efficient directional power flow. All-wheel-drive electric vehicles use bevel gears inside differentials, distributing power between axles for improved traction, stability, and driving efficiency. Electric commercial vehicles, buses, construction equipment, and agricultural machinery require durable bevel gearboxes handling frequent starts, heavy loads, and continuous duty cycles. Marine electrification drives demand for corrosion-resistant bevel gearboxes supporting electric propulsion systems and auxiliary drives. Sensor-integrated modular bevel gearbox designs support predictive maintenance, regenerative braking loads, and compatibility with emerging electric motor technologies across vehicle platforms.

Challenges

How are maintenance requirements and reliability concerns creating obstacles for the bevel gearbox market?

The bevel gearbox industry faces major challenges from high maintenance demands and strict reliability expectations affecting cost, ownership, and customer satisfaction. Bevel gearboxes require regular lubrication, including oil changes, filter replacement, and contamination inspection, to reduce wear and the risk of failure. Complex bevel gear tooth geometry makes uniform lubrication difficult inside compact housings under centrifugal forces and harsh industrial conditions. Heavy industry environments expose bevel gearboxes to dust, moisture, vibration, and temperature extremes, accelerating wear and seal damage. Installation misalignment, foundation movement, and unbalanced loads create vibration, causing bearing fatigue, gear tooth damage, and noise issues. Inspection, diagnosis, and repair often require disassembly or advanced condition monitoring equipment, thereby increasing downtime and maintenance complexity.

Spare parts shortages, limited technician availability, and training needs raise service delays and rebuild costs. End users seek longer service intervals, quieter operation, leak prevention, and durable bevel gearbox designs supporting industrial uptime goals. Predictive maintenance sensors, improved sealing materials, and advanced lubrication systems remain key innovation priorities across the bevel gearbox market.

Bevel Gearbox Market : Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Bevel Gearbox Market Research Report |

| Market Size in 2024 | USD 4.21 Billion |

| Market Forecast in 2034 | USD 6.81 Billion |

| Growth Rate | CAGR of 4.92% |

| Number of Pages | 220 |

| Key Companies Covered | Siemens AG, Bonfiglioli Riduttori S.p.A., Dana Incorporated, Sumitomo Heavy Industries Ltd., Rexnord Corporation, Brevini Power Transmission S.p.A., Cone Drive Operations Inc., Rossi S.p.A., Renold Plc, Elecon Engineering Company Limited, Kissling AG, Wikov Industry a.s., NGC Transmission Europe S.p.A., Kumera Corporation, and David Brown Santasalo |

| Segments Covered | By Gear Type, By Application, By Material, By Configuration, And By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Bevel Gearbox Market: Segmentation

The global bevel gearbox market is segmented based on gear type, application, material, configuration, and region.

Based on gear type, the global bevel gearbox industry is segregated into straight bevel gears, spiral bevel gears, zerol bevel gears, hypoid bevel gears, miter gears, and others. Spiral bevel gears lead the market due to their superior performance characteristics, including smoother operation, higher load capacity, reduced noise compared to straight bevel designs, and the ability to operate at higher speeds with improved efficiency.

Based on application, the industry is segmented into automotive, industrial machinery, aerospace, construction equipment, marine, and power generation. Automotive leads the market due to the widespread use of bevel gearboxes in differential systems, the large global vehicle production volume, and the increasing adoption of bevel gearboxes in electric vehicle powertrains.

Based on material, the global bevel gearbox market is classified into steel, cast iron, aluminum alloy, bronze, and composite materials. Steel is expected to lead the market during the forecast period due to its excellent strength-to-weight ratio, durability under high loads and stresses, and cost-effectiveness for most industrial applications.

Based on configuration, the global market is divided into right-angle, horizontal, vertical, and custom configurations. Right-angle holds the largest market share due to the common requirement for ninety-degree directional changes in machinery layouts, standardization that reduces costs, and compatibility with most industrial applications.

Bevel Gearbox Market: Regional Analysis

What factors are contributing to Asia Pacific's dominance in the global bevel gearbox market?

Asia Pacific is estimated to grow at a CAGR of around 7.8% during the forecast period, remaining the fastest-growing region in the global bevel gearbox market. Asia Pacific leads the bevel gearbox market due to large manufacturing capacity, rapid industrial growth, expanding automotive output, and ongoing infrastructure development across countries. China stands as the largest producer of industrial machinery, automotive vehicles, construction equipment, and power systems using high volumes of bevel gearboxes. Strong investment in manufacturing technology, automation, and workforce training supports advanced bevel gear production and cost-efficient large-scale output. India shows fast growth in automotive manufacturing, construction activity, infrastructure expansion, and industrial equipment demand, thereby increasing bevel gearbox consumption nationwide. Japan offers high-precision manufacturing expertise, producing bevel gearboxes for robotics, automotive systems, industrial automation, and advanced motion control equipment.

South Korea supports demand through shipbuilding, heavy machinery, automotive production, and marine equipment requiring durable high-torque bevel gearboxes. Southeast Asian countries, including Thailand, Vietnam, and Indonesia, attract global manufacturers building factories serving regional and export markets. Large infrastructure projects across the Asia Pacific involve rail networks, ports, highways, airports, and smart cities using construction machinery with reliable bevel gearboxes. Competitive labor costs, supply chain maturity, and component availability support affordable bevel gearbox manufacturing compared with Western regions. Government industrial policies encourage domestic production, technological upgrading, export growth, and the localization of gearbox manufacturing capabilities.

Renewable energy expansion across coastal regions drives demand for bevel gearboxes used in wind turbines, yaw systems, and pitch control applications. Growth in agricultural mechanization increases tractor and implement sales, with bevel gearboxes used for efficient power transfer across farming operations. Export-focused manufacturing hubs strengthen the Asia Pacific position, supplying bevel gearboxes to global automotive, industrial, and renewable energy markets. Established logistics networks, ports, supplier ecosystems, and regional trade agreements further support the sustained growth of the Asia Pacific bevel gearbox market.

North America maintains a significant market share.

North America is estimated to grow at a CAGR of around 3.5% during the forecast period, maintaining its position as the second-leading region in the bevel gearbox market. North America holds a strong position in the bevel gearbox market through advanced manufacturing capabilities, innovative product development, and wide industrial usage across multiple sectors. The United States supports large automotive production with major manufacturers, supplier networks, and continuous demand for bevel gearboxes used in vehicles and driveline systems. Aerospace and defense industries across North America require high-precision bevel gearboxes meeting strict performance, safety, and durability standards.

Oil and gas operations across onshore and offshore locations depend on heavy equipment using robust bevel gearboxes for drilling, pumping, and refining processes. Construction activity covering infrastructure, commercial buildings, and residential projects sustains a steady demand for machinery equipped with reliable bevel gearbox solutions. Agricultural productivity across the Midwest relies on mechanized equipment using bevel gearboxes in tractors, harvesters, planters, and irrigation systems. Mining operations that extract coal, metals, and industrial minerals use heavy machinery that requires durable bevel gearboxes under extreme load conditions. Renewable energy expansion, especially wind farms across the Great Plains, increases demand for bevel gearboxes used in yaw and pitch systems. Advanced manufacturing methods, including precision machining, automation, and additive manufacturing, support efficient domestic bevel gearbox production.

Well-developed distribution networks across North America provide fast spare parts availability, technical support, and aftermarket service for bevel gearbox users. A skilled workforce with mechanical engineering expertise supports custom bevel gearbox design, assembly, testing, and application-specific optimization. Intellectual property protection encourages innovation, investment, and long-term development of advanced bevel gearbox technologies. Stable regulatory frameworks, advanced infrastructure, and strong industrial demand continue supporting the steady growth of the North America bevel gearbox market.

Recent Developments

- In November 2025, Milestone Gears Ltd filed a Draft Red Herring Prospectus with SEBI to raise ₹1,100 crores through an IPO, underlining expansion plans for precision gear manufacturing, including bevel gears and drivetrain components.

Bevel Gearbox Market: Competitive Analysis

The leading players in the global bevel gearbox market are

- Siemens AG

- Bonfiglioli Riduttori S p A

- Dana Incorporated

- Sumitomo Heavy Industries Ltd

- Rexnord Corporation

- Brevini Power Transmission S p A

- Cone Drive Operations Inc

- Rossi S p A

- Renold Plc

- Elecon Engineering Company Limited

- Kissling AG

- Wikov Industry a s

- NGC Transmission Europe S p A

- Kumera Corporation

- David Brown Santasalo

The global bevel gearbox market is segmented as follows:

By Gear Type

- Straight Bevel Gears

- Spiral Bevel Gears

- Zerol Bevel Gears

- Hypoid Bevel Gears

- Miter Gears

- Others

By Application

- Automotive

- Industrial Machinery

- Aerospace

- Construction Equipment

- Marine

- Power Generation

By Material

- Steel

- Cast Iron

- Aluminum Alloy

- Bronze

- Composite Materials

By Configuration

- Right Angle

- Horizontal

- Vertical

- Custom Configurations

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed