Global Abrasive Waterjet Cutting Machine Market Size, Share, Report 2034

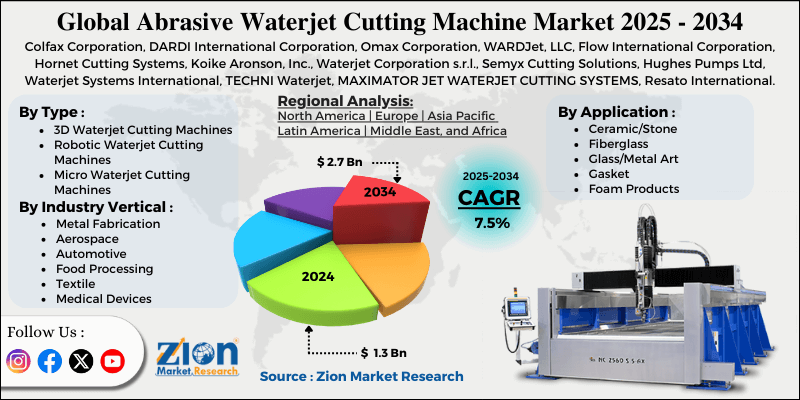

Abrasive Waterjet Cutting Machine Market By Type (3D Waterjet Cutting Machines, Robotic Waterjet Cutting Machines, and Micro Waterjet Cutting Machines), By Application (Exotic Metal & Non-Traditional Material, Ceramic/Stone, Fiberglass, Glass/Metal Art, Gasket, and Foam Products), By Industry Vertical (Metal Fabrication, Aerospace, Automotive, Food Processing, Machine Manufacturing, Textile, and Medical Devices), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

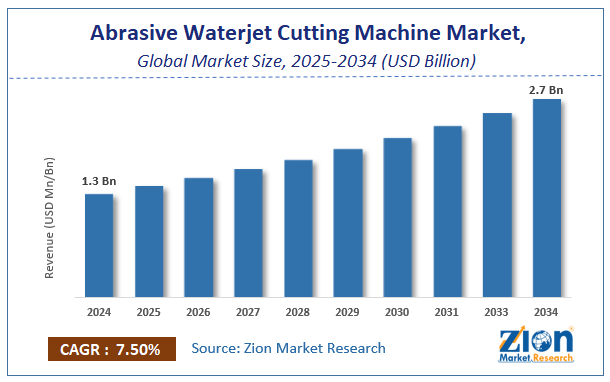

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 1.3 Billion | USD 2.7 Billion | 7.5% | 2024 |

Abrasive Waterjet Cutting Machine Industry Prospective:

The global abrasive waterjet cutting machine market size was worth around USD 1.3 billion in 2024 and is predicted to grow to around USD 2.7 billion by 2034, with a compound annual growth rate (CAGR) of roughly 7.5% between 2025 and 2034.

Key Insights

- As per the analysis shared by our research analyst, the global abrasive waterjet cutting machine market is estimated to grow annually at a CAGR of around 7.5% over the forecast period (2025-2034).

- In terms of revenue, the global abrasive waterjet cutting machine market size was valued at around USD 1.3 billion in 2024 and is projected to reach USD 2.7 billion by 2034.

- Increasing demand from the end-use industry is expected to drive the abrasive waterjet cutting machine market over the forecast period.

- Based on the type, the 3D waterjet cutting machines segment is expected to capture the largest market share over the projected period.

- Based on the application, the exotic metal & non-traditional material segment is expected to capture the largest market share over the projected period.

- Based on the industry vertical, the metal fabrication segment is expected to capture the largest market share over the projected period.

- Based on region, North America is expected to dominate the market during the forecast period.

Abrasive Waterjet Cutting Machine Market: Overview

An abrasive waterjet cutting machine is a type of industrial equipment that uses a high-pressure stream of water mixed with abrasive particles, such as garnet, to cut metals, stone, glass, and composites with very precise control. The process starts with a high-pressure pump that raises the water pressure to 60,000 psi or more. The water then passes through a small opening, creating a supersonic jet. Further, abrasive particles are added to the mixing chamber or nozzle, where they are accelerated to wear down the workpiece without creating hot spots.

This flexible, non-thermal machining method is great for manufacturing, aerospace, and fabrication, as it can handle thicknesses from 1 mm to 250 mm, requires little force, and works with tolerances of +/- 0.005 inches. The abrasive waterjet cutting machine market is being driven by several factors, including growth in metal-cutting and fabrication workloads, aerospace, automotive, and advanced manufacturing needs, a shift toward 5-axis and more complex cutting, and automation/ industry 4.0 integration. However, the high upfront capital cost poses a major challenge to the industry's growth.

Abrasive Waterjet Cutting Machine Market Dynamics

Growth Drivers

How does the growing focus on sustainability propel the growth of the abrasive waterjet cutting machines industry?

The abrasive waterjet cutting machines market is growing as manufacturers strive to make their products cleaner and more environmentally friendly. Abrasive waterjet cutting doesn't make any heat-affected zones, noxious fumes, or dangerous emissions like laser or plasma cutting does. This lowers scrap rates and improves material efficiency by reducing energy loss, material deformation, and the need for secondary finishing. The approach also enables precise cuts with narrow kerf widths, reducing waste and improving manufacturing efficiency.

Abrasive waterjet devices can work with recycled metals, composites, glass, and stone without altering their properties. This aligns with the ideals of the circular economy and green manufacturing. Also, an increasing number of individuals are employing systems for recycling water and recovering abrasives. These systems consume less water and generate less waste, making the machines better for the environment. The need for abrasive waterjet cutting machines is expanding as industries, including aerospace, automotive, metal fabrication, and construction, place greater emphasis on complying with environmental legislation and ESG rules.

Restraints

High upfront capital cost is impeding the industry's growth

The high initial capital cost remains a major barrier to the growth of the abrasive waterjet cutting machine market. Ultra-high-pressure pumps, CNC-controlled cutting tables, abrasive supply systems, catcher tanks, and water treatment equipment are all highly expensive; therefore, abrasive waterjet systems require a significant upfront investment. Users often have to pay for additional infrastructure, including reinforced flooring, power supply upgrades, and safety measures, in addition to the main equipment. This raises the cost of capital. This high entry barrier makes it hard for small and medium-sized firms and job shops to adopt it, especially when plasma or laser cutting equipment is sufficient for basic tasks. Because of this, budget limits and longer payback periods continue to impede industry growth, especially in manufacturing industries that are sensitive to price changes and are growing.

Opportunities

Will technological advancement offer a potential opportunity for the abrasive waterjet cutting machines industry's growth?

There are numerous technological developments in the Abrasive Waterjet Cutting Machine Market that enhance cutting accuracy and efficiency. Manufacturers can now achieve tighter tolerances and higher cutting speeds due to enhanced control systems and improved nozzle design. Adding automation and robotics to waterjet systems, for example, makes things easier, reduces labor costs, and lessens the risk of human error. Recent research shows that the market for waterjet cutting technology will increase at a compound annual growth rate of about 7.8% over the next five years. The primary reason for this rise is the demand for high-quality cutting solutions across sectors such as aerospace, automotive, and metal manufacturing.

Challenges

Does slower cutting speed/lower throughput, as compared to laser or plasma, pose a major challenge to the abrasive waterjet cutting machine market expansion?

The abrasive waterjet cutting machine business has been struggling to grow, as cutting speeds are slower and throughput is lower than with laser or plasma cutting. Abrasive waterjet technology is highly accurate and can cut without heat, but it typically requires longer processing times, especially when multiple parts are being cut. For companies that want to make many things quickly, laser and plasma cutting technologies often enable faster processing speeds and increased productivity, thereby lowering the cost per part for large quantities. Because of their lower speed, abrasive waterjet machines are less suitable for applications that require high throughput. This makes them less competitive in businesses where efficiency and cycle time are important, which slows overall market growth.

Abrasive Waterjet Cutting Machine Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Abrasive Waterjet Cutting Machine Market |

| Market Size in 2024 | USD 1.3 Billion |

| Market Forecast in 2034 | USD 2.7 Billion |

| Growth Rate | CAGR of 7.5% |

| Number of Pages | 290 |

| Key Companies Covered | Colfax Corporation, DARDI International Corporation, Omax Corporation, WARDJet, LLC, Flow International Corporation, Hornet Cutting Systems, Koike Aronson, Inc., Waterjet Corporation s.r.l., Semyx Cutting Solutions, Hughes Pumps Ltd, Waterjet Systems International, TECHNI Waterjet, MAXIMATOR JET WATERJET CUTTING SYSTEMS, Resato International, and Uhde High Pressure Technologies GmbH, among others. |

| Segments Covered | By Type, By Application, By Industry Vertical and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America,The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Abrasive Waterjet Cutting Machine Market: Segmentation

Type Insights

The 3D waterjet cutting machines segment is expected to capture the largest market share over the forecast period. Companies in the aerospace, automotive, and advanced fabrication industries need more complicated shapes and precise 3D contours. Because 3D waterjet systems with multi-axis motion and advanced CNC control can cut complex parts from a wide range of hard materials with minimal heat impact, they are attracting increasing investment. This additional flexibility has played a big role in the overall growth of market revenue. The largest share of the waterjet cutting market comprises 3D waterjet products, which drive global sales. Ongoing scientific advancement, increased factory automation, and more applications in industries that require precision and minimal thermal distortion all help drive sales. All of these factors increase demand for advanced 3D abrasive waterjet solutions, which drives prices up.

Application Insights

The exotic metal & non-traditional material segment is expected to hold the largest revenue share over the projected period. The fact that exotic metals and non-traditional materials endure for extended periods in industries that require high accuracy and speed sets them apart. This category is the most popular because it serves important industries like aerospace and automotive, where titanium and composites are used a lot. These materials need special cutting technologies because of their unique properties and performance needs.

Industry Vertical Insights

The metal fabrication segment is expected to capture a substantial market share. This is because the technology can quickly and accurately work with a wide range of metals used in many different industries. Metal fabricators increasingly use abrasive waterjet systems because they can cut high-strength, complex alloys such as stainless steel, aluminum, and titanium, as well as high-hardness steels, without creating a heat-affected zone. This keeps the material's properties intact and cuts down on the need for finishing after cutting. This flexibility lets fabricators integrate different cutting methods into one solution, which speeds up the workflow and lowers operational expenses.

Abrasive Waterjet Cutting Machine Market: Regional Analysis

North America accounts for 45% of the revenue share of the abrasive waterjet cutting machine market during the analysis period. The region's strong industrial base and early use of advanced manufacturing technology are driving this growth. The main driver of growth is increased demand from the aerospace and defense, automotive, industrial machinery, and metal fabrication industries that require high precision and material integrity. Because it can cut cold, abrasive waterjet cutting is becoming more popular among North American manufacturers. This means there are fewer heat-affected zones and that it can efficiently handle high-strength metals, composites, and other materials that aren't typically used.

Also, more money is going into automation, multi-axis and 3D waterjet systems, and Industry 4.0-ready manufacturing lines. This is making work more productive and encouraging people to upgrade their equipment. Because the area prioritizes environmental protection, worker safety, and stringent environmental regulations, waterjet technology is preferred over older thermal cutting methods. Because of this, the North American abrasive waterjet cutting machine market is projected to grow steadily as more industries modernize and require precise cutting solutions.

Abrasive Waterjet Cutting Machine Market: Competitive Analysis

The global abrasive waterjet cutting machine market is dominated by players like-

- Colfax Corporation

- DARDI International Corporation

- Omax Corporation

- WARDJet

- Flow International Corporation

- Hornet Cutting Systems

- Koike Aronson

- Waterjet Corporation s.r.l.

- Semyx Cutting Solutions

- Hughes Pumps Ltd

- Waterjet Systems International

- TECHNI Waterjet

- MAXIMATOR JET WATERJET CUTTING SYSTEMS

- Resato International

- Uhde High Pressure Technologies GmbH

- among others.

The global abrasive waterjet cutting machine market is segmented as follows:

By Type

- 3D Waterjet Cutting Machines

- Robotic Waterjet Cutting Machines

- Micro Waterjet Cutting Machines

By Application

- Exotic Metal & Non-Traditional Material

- Ceramic/Stone

- Fiberglass

- Glass/Metal Art

- Gasket

- Foam Products

By Industry Vertical

- Metal Fabrication

- Aerospace

- Automotive

- Food Processing

- Machine Manufacturing

- Textile

- Medical Devices

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

What are the emerging trends and innovations impacting the abrasive waterjet cutting machine market?

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed