Global Ultrasonic Welding Systems Market Size, Share, Growth Analysis Report - Forecast 2034

Ultrasonic Welding Systems Market By Equipment Type (Handheld Ultrasonic Welders, Automated Ultrasonic Welders, Bench-Top Ultrasonic Welders, Custom Ultrasonic Systems), By Application (Automotive Industry, Electrical and Electronics, Medical Devices, Textiles and Nonwovens, Plastic Packaging, Consumer Goods), By Material Type (Thermoplastics, Thermosetting Plastics, Metals, Composites, Rubber), By Industry Vertical (Manufacturing, Aerospace, Construction, Medical and Healthcare, Packaging), By Technology (Continuous Ultrasonic Welding, Pulsed Ultrasonic Welding, Ultrasonic Spot Welding, Ultrasonic Sealing), and By Region: Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

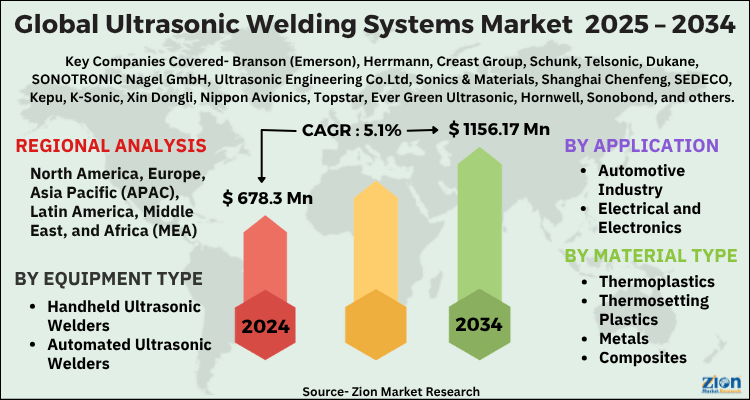

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 678.3 Million | USD 1156.17 Million | 5.1% | 2024 |

Global Ultrasonic Welding Systems Market: Industry Perspective

The global ultrasonic welding systems market size was worth around USD 678.3 Million in 2024 and is predicted to grow to around USD 1156.17 Million by 2034 with a compound annual growth rate (CAGR) of roughly 5.1% between 2025 and 2034. The report analyzes the global ultrasonic welding systems market's drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the ultrasonic welding systems industry.

Global Ultrasonic Welding Systems Market: Overview

To form a solid-state weld between the components that are being held together under pressure, ultrasonic welding uses high-frequency ultrasonic acoustic vibrations that are locally applied. It is frequently used for connecting metals and polymers, particularly when the two materials are different. In ultrasonic welding, the materials are joined together without the need of connecting bolts, nails, solder, or adhesives. Because the temperature is kept much below the melting point of the metals being joined, any undesirable qualities that would result from the metal being exposed to high temperatures are avoided. The market growth of ultrasonic welding systems is being driven by the rising automotive industry, growing adoption in electronics, increasing medical device manufacturing, and advancements in the packaging industry.

Global Ultrasonic Welding Systems Market: Growth Drivers

The increasing automotive sector drives market growth

Ultrasonic welding systems have found extensive applications within the automotive industry due to their ability to provide reliable and efficient joining solutions for various materials used in automotive manufacturing. The application of ultrasonic welding in vehicles is in plastic component assembly, exterior components, electrical & electronics components, and air intake & filtration systems. Thus, the ultrasonic welding system market demand is driven by the growing automotive industry. For instance, according to the Society of Indian Automobile Manufacturers, from 30,69,523 to 38,90,114 units were sold overall as passenger vehicles. In FY-2022–23, sales of Passenger Cars climbed from 14,67,039 to 17,47,376, Utility Vehicles from 14,89,219 to 20,03,718, and Vans from 1,13,265 to 1,39,020 units, all compared to the prior year. Furthermore, from 7,16,566 to 9,62,468 units were sold overall in the commercial vehicle category. In FY-2022–23, sales of Light Commercial Vehicles climbed from 4,75,989 to 6,03,465 units while those of Medium and Heavy Commercial Vehicles increased from 2,40,577 to 3,59,003 units compared to the prior year.

Restraints

Material compatibility acting as a major restraint to the market growth

Only materials that can transmit ultrasonic vibrations may be joined using ultrasonic welding, which is very effective for connecting polymers and some metals. Certain businesses may be unable to employ this technique because some sophisticated materials and composites may not be appropriate. Therefore, material compatibility is expected to be a major restraining factor for the ultrasonic welding system industry over the projection period.

Opportunities

Growing product launches offer a lucrative opportunity for market growth

The growing product launches are expected to offer a lucrative opportunity for global ultrasonic welding systems market growth during the forecast period. For instance, in January 2022, Emerson unveiled a brand-new ultrasonic metal welder for connecting wire terminations, conductors, and bigger batteries. For the larger welds needed by electric vehicles, batteries, and energy storage systems, Emerson's new BransonTM GMX-HP ultrasonic metal welder combines increased power and downforce with a modular equipment design and features that make installation and automation for machine builders and manufacturers easier. Increased weld power is provided by a large 8-kilowatt, 20-kilohertz power supply in the new GMX-HP. A direct-press actuator that transmits welding power and has precise distance sensors, twin linear bearing guides, and a dynamic pressure trigger provides more part-holding downforce and the high stability required for consistent weld quality. Thereby, driving the market growth.

Challenges

Limited thickness and complex joint designs pose a major challenge to market growth

The best materials for ultrasonic welding are those that are thin to medium thick. Heavy-duty applications are limited by the challenge and the need for specialist equipment associated with welding very thick materials. Additionally, even though ultrasonic welding is adaptable, it might not be appropriate for excessively intricate joint designs or inaccessible places. Alternative welding techniques or human work may be necessary in such circumstances. Thus, this is expected to pose a major challenge to the market growth.

Key Insights

- As per the analysis shared by our research analyst, the global ultrasonic welding systems market is estimated to grow annually at a CAGR of around 5.1% over the forecast period (2025-2034).

- Regarding revenue, the global ultrasonic welding systems market size was valued at around USD 678.3 Million in 2024 and is projected to reach USD 1156.17 Million by 2034.

- The ultrasonic welding systems market is projected to grow at a significant rate due to rising automation in manufacturing, increasing demand for precision joining in electronics and automotive sectors, growing adoption of eco-friendly welding solutions, and expanding applications in medical device assembly.

- Based on Equipment Type, the Handheld Ultrasonic Welders segment is expected to lead the global market.

- On the basis of Application, the Automotive Industry segment is growing at a high rate and will continue to dominate the global market.

- Based on the Material Type, the Thermoplastics segment is projected to swipe the largest market share.

- By Industry Vertical, the Manufacturing segment is expected to dominate the global market.

- In terms of Technology, the Continuous Ultrasonic Welding segment is anticipated to command the largest market share.

- Based on region, Asia-Pacific is predicted to dominate the global market during the forecast period.

Global Ultrasonic Welding Systems Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Ultrasonic Welding Systems Market |

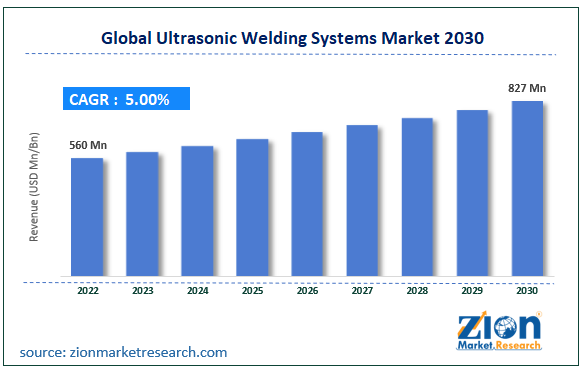

| Market Size in 2022 | USD 560 Million |

| Market Forecast in 2030 | USD 827 Million |

| Growth Rate | CAGR of 5.0% |

| Number of Pages | 211 |

| Key Companies Covered | Creast Group, Branson (Emerson), Dukane, Telsonic AG, Schunk Group, Herrmann, Weihai KAER Ultrasonic Engineering Co. Ltd., Shanghai Chenfeng, SEDECO, Sonics & Materials Inc., SONOTRONIC Nagel GmbH, Kepu, K-Sonic, Xin Dongli, Nippon Avionics, Topstar GmbH, Ever Green Ultrasonic, Hornwell, Sonobond, and others. |

| Segments Covered | By Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2022 |

| Historical Year | 2017 to 2021 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Global Ultrasonic Welding Systems Market: Segmentation Analysis

The global ultrasonic welding systems market is segmented based on Equipment Type, Application, Material Type, Industry Vertical, Technology, and region. All the segments have been analyzed based on present and future trends and the market is estimated from 2025 to 2034.

Based on Equipment Type, the global ultrasonic welding systems market is divided into Handheld Ultrasonic Welders, Automated Ultrasonic Welders, Bench-Top Ultrasonic Welders, Custom Ultrasonic Systems.

On the basis of Application, the global ultrasonic welding systems market is bifurcated into Automotive Industry, Electrical and Electronics, Medical Devices, Textiles and Nonwovens, Plastic Packaging, Consumer Goods.

By Material Type, the global ultrasonic welding systems market is split into Thermoplastics, Thermosetting Plastics, Metals, Composites, Rubber.

In terms of Industry Vertical, the global ultrasonic welding systems market is categorized into Manufacturing, Aerospace, Construction, Medical and Healthcare, Packaging.

By Technology, the global Ultrasonic Welding Systems market is divided into Continuous Ultrasonic Welding, Pulsed Ultrasonic Welding, Ultrasonic Spot Welding, Ultrasonic Sealing.

The Regional segment includes the current and forecast demand for North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

Global Ultrasonic Welding Systems Market: Regional Analysis

Asia Pacific is expected to grow at the highest CAGR during the projection period

The Asia Pacific is expected to grow at the highest CAGR in the global ultrasonic welding systems market during the forecast period. The growth in the region is attributed to the robust manufacturing base across the industry including automotive, electronics, consumer goods, and others. The growth in the region is especially driven by countries like China, Japan, India, South Korea, and Taiwan. For instance, the APAC region is a major hub for automotive manufacturing. Ultrasonic welding systems find extensive use in assembling plastic components in automobiles, contributing to the growth of the market.

Global Ultrasonic Welding Systems Market: Competitive Analysis

The report provides a company market share analysis to give a broader overview of the key market players. In addition, the report also covers key strategic developments of the market, including acquisitions & mergers, new product launches, agreements, partnerships, collaborations & joint ventures, research & development, and regional expansion of major participants involved in the ultrasonic welding systems market on a global and regional basis.

The global ultrasonic welding systems market is dominated by players like:

- Branson (Emerson)

- Herrmann

- Creast Group

- Schunk

- Telsonic

- Dukane

- SONOTRONIC Nagel GmbH

- Ultrasonic Engineering Co.Ltd

- Sonics & Materials

- Shanghai Chenfeng

- SEDECO

- Kepu

- K-Sonic

- Xin Dongli

- Nippon Avionics

- Topstar

- Ever Green Ultrasonic

- Hornwell

- Sonobond

Global Ultrasonic Welding Systems Market: Segmentation Analysis

The global ultrasonic welding systems market is segmented as follows;

By Equipment Type

- Handheld Ultrasonic Welders

- Automated Ultrasonic Welders

- Bench-Top Ultrasonic Welders

- Custom Ultrasonic Systems

By Application

- Automotive Industry

- Electrical and Electronics

- Medical Devices

- Textiles and Nonwovens

- Plastic Packaging

- Consumer Goods

By Material Type

- Thermoplastics

- Thermosetting Plastics

- Metals

- Composites

- Rubber

By Industry Vertical

- Manufacturing

- Aerospace

- Construction

- Medical and Healthcare

- Packaging

By Technology

- Continuous Ultrasonic Welding

- Pulsed Ultrasonic Welding

- Ultrasonic Spot Welding

- Ultrasonic Sealing

Global Ultrasonic Welding Systems Market: Regional Segment Analysis

- North America

- The U.S.

- Canada

- Mexico

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Australia

- South Korea

- Rest of Asia Pacific

- The Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- Kuwait

- South Africa

- Rest of the Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

Table Of Content

Methodology

FrequentlyAsked Questions

To form a solid-state weld between the components that are being held together under pressure, ultrasonic welding uses high-frequency ultrasonic acoustic vibrations that are locally applied. It is frequently used for connecting metals and polymers, particularly when the two materials are different. In ultrasonic welding, the materials are joined together without the need of connecting bolts, nails, solder, or adhesives. Because the temperature is kept much below the melting point of the metals being joined, any undesirable qualities that would result from the metal being exposed to high temperatures are avoided. The market growth of ultrasonic welding systems is being driven by the rising automotive industry, growing adoption in electronics, increasing medical device manufacturing, and advancements in the packaging industry.

The global ultrasonic welding systems market is expected to grow due to increasing demand from the automotive sector, rising adoption in electronics and medical device manufacturing, and growing advancements in automated packaging applications.

According to a study, the global ultrasonic welding systems market size was worth around USD 678.3 Million in 2024 and is expected to reach USD 1156.17 Million by 2034.

The global ultrasonic welding systems market is expected to grow at a CAGR of 5.1% during the forecast period.

Asia-Pacific is expected to dominate the ultrasonic welding systems market over the forecast period.

Leading players in the global ultrasonic welding systems market include Branson (Emerson), Herrmann, Creast Group, Schunk, Telsonic, Dukane, SONOTRONIC Nagel GmbH, Ultrasonic Engineering Co.Ltd, Sonics & Materials, Shanghai Chenfeng, SEDECO, Kepu, K-Sonic, Xin Dongli, Nippon Avionics, Topstar, Ever Green Ultrasonic, Hornwell, Sonobond, among others.

The report explores crucial aspects of the ultrasonic welding systems market, including a detailed discussion of existing growth factors and restraints, while also examining future growth opportunities and challenges that impact the market.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed