Industrial Gearbox Market Size, Share, Analysis, Trends, Growth, Forecasts, 2034

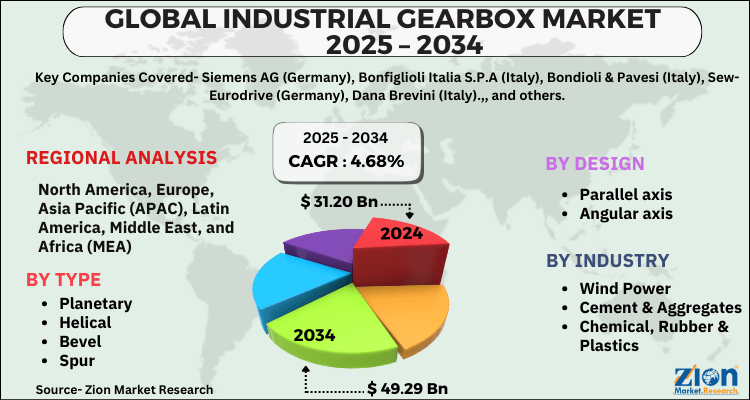

Industrial Gearbox Market By Type(Planetary, Helical, Bevel, Spur, Worm, Other (Helical-Bevel, Planetary Worm)), By Design(Parallel axis, Angular axis, Others (non-coplanar and non-parallel axis)), By Industry(Wind Power, Cement & Aggregates, Chemical, Rubber & Plastics, Construction, Food & Beverage, Marine, Material Handling, Metals & Mining, Power Generation, Recreational Vehicle, Transportation, Industry, Agriculture, Automotive, Others (Aerospace, Defense, Semiconductor, Robotics, Textile, Healthcare)), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data and Forecasts 2025 - 2034

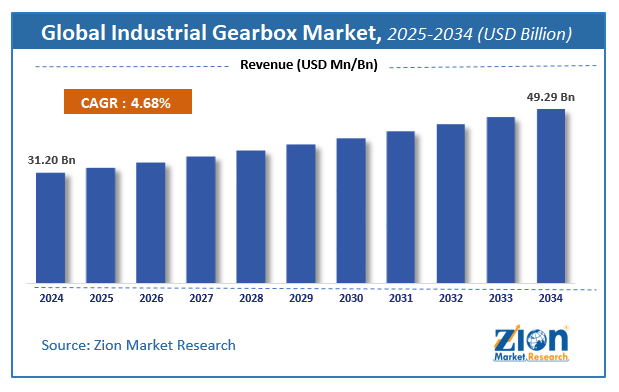

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 31.20 Billion | USD 49.29 Billion | 4.68% | 2024 |

Industrial Gearbox Market Size

The global industrial gearbox market size was worth around USD 31.20 Billion in 2024 and is predicted to grow to around USD 49.29 Billion by 2034 with a compound annual growth rate (CAGR) of roughly 4.68% between 2025 and 2034. The report analyzes the global industrial gearbox market's drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the industrial gearbox industry.

Industrial Gearbox Market: Overview

An industrial gearbox is a machine thatis required by various machine parts and components to function reliably and safely. As amatter of fact, the industrial gearbox acts as a mainstream component for every automobile or vehicle. Industrial gearboxes are also manufactured to control gear and torque of automobiles. Industrial gearbox is enclosed machinery equipment that mainly transmits mechanical energy to output devices. These gearboxes consist of a series of integrated gears enclosed in a system. Industrial gearboxes are used in a wide range of applications or purposes in a diverse range of devices. In simple words, industrial gearboxes simply transfer mechanical energy from one device to another by reducing the speed, thus increasing the torque.

An enclosed system that conveys mechanical energy to an output device is known as an industrial gearbox. Gearboxes can change the speed, torque, and other characteristics of the energy to make it usable. Gearboxes are found in a wide range of devices and serve a variety of functions. To improve torque and speed, these machines can reduce the rate of rotation. The growing use of automation across all industrial sectors is a primary driver for the expansion of the industrial gearbox industry, however direct drive systems are a stumbling block. Misalignment, lubrication concerns, bearing issues, and thermal instability are just a few of the market's challenges.

The global market for industrial gearboxes is primarily driven by the increasing acceptance of Industry 4.0 trends, as well as the rising usage of automated machinery. Furthermore, the introduction of severe government requirements for decreasing noise pollution and power overload across industrial units is boosting the use of industrial gearboxes. A large increase in the renewable energy sector is also driving demand for products that absorb kinetic energy in wind or hydro turbines to generate power. The market for industrial gearboxes is being catalysed by the adoption of favourable government regulations and financial incentives for the development of clean and safe power sources.

Key Insights

- As per the analysis shared by our research analyst, the global industrial gearbox market is estimated to grow annually at a CAGR of around 4.68% over the forecast period (2025-2034).

- Regarding revenue, the global industrial gearbox market size was valued at around USD 31.20 Billion in 2024 and is projected to reach USD 49.29 Billion by 2034.

- The industrial gearbox market is projected to grow at a significant rate due to rising demand in manufacturing, power generation, and automotive sectors, along with technological advancements.

- Based on Type, the Planetary segment is expected to lead the global market.

- On the basis of Design, the Parallel axis segment is growing at a high rate and will continue to dominate the global market.

- Based on the Industry, the Wind Power segment is projected to swipe the largest market share.

- Based on region, Asia-Pacific is predicted to dominate the global market during the forecast period.

Industrial Gearbox Market: Growth Drivers

Rising Adoption of Industrial Adoption & Improving Industrialization to drive global market growth

During the forecast period, factors such as rapidly increasing industrialization and rising measures to modernise industrial infrastructure will propel the industrial gearbox market forward. The market's footprint will grow as more applications and government support are made available for developing advanced energy flexible and effective buildings. Increased automated activities, as well as an increase in the number of growing economies, will expand the market's current boundaries..

Industrial Gearbox Market: Restraints

Higher maintenances costs in Industrial Gearboxes to hamper the market growth

Periodic maintenance, including an oil change, is required for all gearboxes. Contamination from dirt, debris, and other fluids such as water should be examined on a regular basis. Oil should also be replaced on a regular basis, depending on the number of hours of operation and the temperature of the oil.

Global Industrial Gearbox Market: Segmentation

The global Industrial Gearbox market is segregated based on type, desgin, industry, and region.

By type, the market is classified into planetary, helical, bevel, spur, worm, and other (helical-bevel, planetary worm). The teeth of a helical gear cut at an angle to the gear's face in a helical gearbox. When two teeth make contact during the process, it happens gradually, starting at one end of the tooth and continuing until the gear spins in complete engagement. As a result, it is capable of running smooth operations while providing high thrust outputs. It is the most commonly utilized gear in vehicle transmissions since it creates a lot of thrust. Helical gearboxes are distinguished by their extraordinarily high output torques, quiet operation, and long service life. After planetary gearboxes, helical gearboxes are the most efficient gearboxes in the business, working at 98 percent efficiency. Helical gearboxes are used in key industries such as power, fertilizer, rolling mills, automobile, steel, and port industries, as well as manufacturing sectors such as plastics, textiles, and food, due to their high efficiency and thrust-generating capabilities.

Wind power, cement & aggregate, chemical, rubber & plastic, construction, food & beverage, maritime, material handling, metals & mining, power generation, recreational vehicles, transport industry, agricultural, automotive, and others are the end-user segments of the market. The market for wind power is predicted to increase at the fastest rate. With 38.6 GW of wind capacity as of 2020, India is the world's fourth-largest onshore wind market by installations. The country's wind power sector has been developing due to two major factors: increased energy demand and government mandates.

Industrial Gearbox Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Industrial Gearbox Market |

| Market Size in 2024 | USD 31.20 Billion |

| Market Forecast in 2034 | USD 49.29 Billion |

| Growth Rate | CAGR of 4.68% |

| Number of Pages | 188 |

| Key Companies Covered | Siemens AG (Germany), Bonfiglioli Italia S.P.A (Italy), Bondioli & Pavesi (Italy), Sew-Eurodrive (Germany), Dana Brevini (Italy).,, and others. |

| Segments Covered | By Type, By Design, By Industry, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2020 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Recent Developments

- March 2021: Nanjing High Accuracy Drive Equipment Manufacturing Group Co., a company based in NGC, placed an order for roughly 656 gearboxes, which included specifically PDM460 dual-stage gears. The Perth subway system in Australia has placed an order for gearboxes. The PDM460 subway gearbox utilized in this order was advertised as having strong bearing capacity, great reliability, and other qualities.

- October 2020- It's ideal for varied loads and high vibrations (improves gearbox transmission performance) in a temperature range of -25°C to 50°C.At the China Wind Power (CWP) 2020 show in, Nanjing High Accurate Drive Equipment Manufacturing Group Co. Ltd (NGC) debuted its WinGearTM brand 3.x MW main gearbox platform. The gearbox uses improved bearing technology and a modular design idea to achieve high torque density while lowering electricity costs. Moreover, the gearbox is lighter in weight as compared to other industrial gearboxes available.

Global Industrial Gearbox Market: Regional Landscape

Due to rising demand for gearboxes in various applications such as the manufacturing sector, power industry, and others, the Asia-Pacific region accounted for a major proportion of the industrial gearbox market in 2020. China has played a critical role in the global industrial sector's expansion. In the chemical, steel, power, and cement industries, the country is the market leader, and it is also a major player in the petrochemical and refining industries. In addition, steel production in 2020 is expected to expand by 6.5 percent over the previous year. China is the world's largest producer and exporter of crude steel, accounting for more than half of worldwide output. Steel consumption is likely to rise as a result of China's One Belt One Road project, which aims to close the region's infrastructural gap. Furthermore, one refinery is undergoing expansion as of August 2021, and three new refineries are slated to start operations in 2021. By 2022, one refinery is planned to be operational. As a result, the country is likely to see a growth in industrial gearbox installations in the energy sector throughout the projection period, thanks to the expansion of refineries and petrochemical businesses, as well as the planned coal-fired plants.

Global Industrial Gearbox Market: Competitive Landscape

The report provides a company market share analysis to give a broader overview of the key market players. In addition, the report also covers key strategic developments of the market, including acquisitions & mergers, new product launches, agreements, partnerships, collaborations & joint ventures, research & development, and regional expansion of major participants involved in the industrial gearbox market on a global and regional basis.

Some of the main competitors dominating the global Industrial Gearbox market include

- Siemens AG (Germany)

- Bonfiglioli Italia S.P.A (Italy)

- Bondioli & Pavesi (Italy)

- Sew-Eurodrive (Germany)

- Dana Brevini (Italy).

Global Industrial Gearbox market is segmented as follows:

By Type

- Planetary

- Helical

- Bevel

- Spur

- Worm

- Other (Helical-Bevel, Planetary Worm)

By Design

- Parallel axis

- Angular axis

- Others (non-coplanar and non-parallel axis)

By Industry

- Wind Power

- Cement & Aggregates

- Chemical, Rubber & Plastics

- Construction

- Food & Beverage

- Marine

- Material Handling

- Metals & Mining

- Power Generation

- Recreational Vehicle

- Transportation Industry

- Agriculture

- Automotive

- Others (Aerospace, Defense, Semiconductor, Robotics, Textile, Healthcare)

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

The global industrial gearbox market is expected to grow due to rising automation in industries, increasing adoption in wind energy applications, and growing demand for efficient power transmission systems in manufacturing and construction.

According to a study, the global industrial gearbox market size was worth around USD 31.20 Billion in 2024 and is expected to reach USD 49.29 Billion by 2034.

The global industrial gearbox market is expected to grow at a CAGR of 4.68% during the forecast period.

Asia-Pacific is expected to dominate the industrial gearbox market over the forecast period.

Leading players in the global industrial gearbox market include Siemens AG (Germany), Bonfiglioli Italia S.P.A (Italy), Bondioli & Pavesi (Italy), Sew-Eurodrive (Germany), Dana Brevini (Italy).,, among others.

The report explores crucial aspects of the industrial gearbox market, including a detailed discussion of existing growth factors and restraints, while also examining future growth opportunities and challenges that impact the market.

RelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed