Conformal Coating Market Size, Share, Trends and Analysis 2032

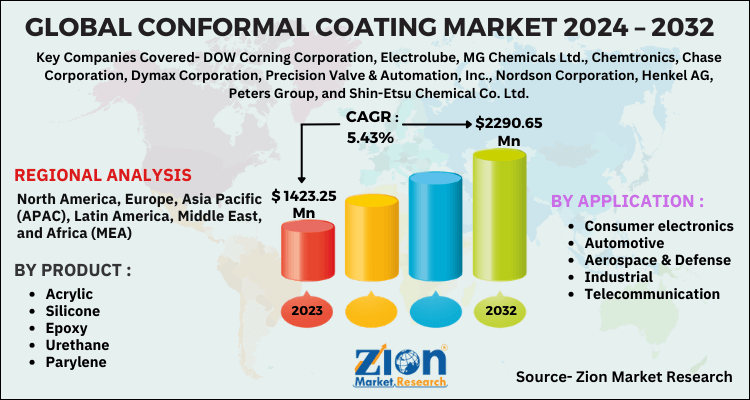

Conformal Coating Market By Product (Acrylic, Silicone, Epoxy, Urethane, and Parylene) and By Application (Consumer electronics, Automotive, Aerospace & Defense, Industrial, and Telecommunication): Global Industry Perspective, Comprehensive Analysis and Forecast, 2024-2032

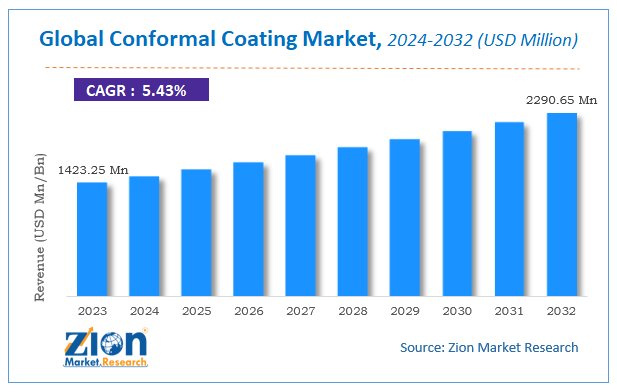

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 1423.25 Million | USD 2290.65 Million | 5.43% | 2023 |

Conformal Coating Market Insights

According to Zion Market Research, the global Conformal Coating Market was worth USD 1423.25 Million in 2023. The market is forecast to reach USD 2290.65 Million by 2032, growing at a compound annual growth rate (CAGR) of 5.43% during the forecast period 2024-2032. The report offers a comprehensive analysis of the market, highlighting the factors that will determine growth, potential challenges, and opportunities that could emerge in the Conformal Coating Market industry over the next decade.

Conformal Coating Market: Overview

Conformal coatings are thin polymeric films which are used for contouring printed circuit board, thereby protecting board component. Conformal coatings are generally of thickness 25-250 micrometers and protect printed circuit boards from moisture, air, chemicals, dust, and high temperature. Conformal coatings are of four types: silicone, acrylic, varnish, and urethane. Type of material of these coatings is selected based on manufacturing processes adopted and surrounding operating conditions. Conformal coatings are applied in variety of methods such as spraying, dip coating, brushing, and dispensing.

Conformal coatings are mainly utilized in providing protection to PCBs from harsh environmental conditions and avoid mold growth, corrosion, and component failures. Conformal coatings are applicable in a wide range of industries such as aerospace, consumer electronics, automotive, and medical as increasing reliability of PCBs is of high importance in such industries to ensure efficient operations. Conformal coatings are of high importance in electromagnetic sensitive components, opened components, optical components, and flexible electronic components.

Conformal Coating Market: Growth Factors

Global semiconductor industry has been driven by rising demand electronic components from industries such as consumer electronics, telecommunications, automotive, and industrial automation. This growth in semiconductor industry worldwide has also been propelled by soaring adoption of automation products for industrial uses. Such growth has propelled the demand for printed circuit boards and various types of electronic components, which is driving the consumption of protecting coatings used on electronic components. Rising consumption of protecting coatings for PCBs is fueling conformal coating market growth.

Automotive, aerospace, and telecommunication industries have experienced adoption of newly advanced innovative technologies for various applications. This trend has accelerated the demand for miniaturized electronic components. Rise in the use of micro-electronic components has also propelled the utilization of coatings in semiconductor applications. Such growth in the use of coatings for avoiding circuit damage should proliferate the demand for conformal coating.

Conformal Coating Market: Segment Analysis

Acrylic is a thermoplastic homopolymer which is used as conformal coating owing to its high dielectric strength and abrasion resistance. Acrylic has been popular among manufacturing companies owing to its easy availability and ability to be removed easily. Use of acrylic conformal coating has increased as these have low cost and reduce overall product cost. Such benefit of acrylic conformal coating has been driving the market growth.

Silicon segment is expected to grow at the highest rate in the global conformal coating market over the forecasted timeline. Silicone conformal coating is utilized for protecting printed circuit boards from physical and thermal shocks, dust, air, moisture, and corrosion. Silicone conformal coating is increasing adopted by semiconductor companies owing to their ability to offer greater protection over a wide range of temperature. Such advantage of silicon resin coatings over different types of conformal coating is likely to fuel the silicon conformal coating market growth.

In terms of applications, the consumer electronics segment held a major share in the global conformal coating market in 2023. Rising sales of consumer electronic goods such as mobile phones, laptops, and home appliances has driven the consumption of electronic components. This rise in the sale of consumer electronic components has augmented the consumption of conformal coating as protection, which should accelerate market growth.

Conformal Coating Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Conformal Coating Market |

| Market Size in 2023 | USD 1423.25 Million |

| Market Forecast in 2032 | USD 2290.65 Million |

| Growth Rate | CAGR of 5.43% |

| Number of Pages | 130 |

| Key Companies Covered | DOW Corning Corporation, Electrolube, MG Chemicals Ltd., Chemtronics, Chase Corporation, Dymax Corporation, Precision Valve & Automation, Inc., Nordson Corporation, Henkel AG, Peters Group, and Shin-Etsu Chemical Co. Ltd |

| Segments Covered | By Product, By Application and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Conformal Coating Market: Regional Analysis Preview

Asia Pacific is home to some of the largest semiconductor markets such as China, Taiwan, Japan, and India. Electronic component sales in Asia Pacific has been rising owing to growing demand for smartphones, laptops, washing machines, and kitchen appliances. This growth in the demand for electronic component has driven the consumption protective coatings in various industries, which is likely to boost the Asia Pacific conformal coating market.

North American region held a significant share in the global conformal coating market in 2023. New trends in electronic industries such as miniaturization of electronic circuits have driven adoption of new manufacturing technologies by companies. Adoption of new technologies is likely to trigger the North America conformal coating market growth.

Conformal Coating Market: Competitive Analysis

The global Conformal Coating market is dominated by players like:

- DOW Corning Corporation

- Electrolube

- MG Chemicals Ltd

- Chemtronics

- Chase Corporation

- Dymax Corporation

- Precision Valve & Automation Inc

- Nordson Corporation

- Henkel AG

- Peters Group

- Shin-Etsu Chemical Co. Ltd.

The global Conformal Coating market is segmented as follows:

By Product

- Acrylic

- Silicone

- Epoxy

- Urethane

- Parylene

By Application

- Consumer electronics

- Automotive

- Aerospace & Defense

- Industrial

- Telecommunication

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

According to Zion Market Research, the global Conformal Coating Market was worth USD 1423.25 Million in 2023. The market is forecast to reach USD 2290.65 Million by 2032.

According to Zion Market Research, the global Conformal Coating Market a compound annual growth rate (CAGR) of 5.43% during the forecast period 2024-2032.

Global semiconductor industry has been driven by rising demand electronic components from industries such as consumer electronics, telecommunications, automotive, and industrial automation. This growth in semiconductor industry worldwide has also been propelled by soaring adoption of automation products for industrial uses. Such growth has propelled the demand for printed circuit boards and various types of electronic components, which is driving the consumption of protecting coatings used on electronic components. Rising consumption of protecting coatings for PCBs is fueling conformal coating market growth.

The Asia Pacific region dominated the global conformal coating market in 2020, constituting a market share of nearly 40%. Asia Pacific is home to some of the largest semiconductor markets such as China, Taiwan, Japan, and India. Electronic component sales in Asia Pacific has been rising owing to growing demand for smartphones, laptops, washing machines, and kitchen appliances. This growth in the demand for electronic component has driven the consumption protective coatings in various industries, which is likely to boost the Asia Pacific conformal coating market.

Some of key players in conformal coating market are DOW Corning Corporation, Electrolube, MG Chemicals Ltd., Chemtronics, Chase Corporation, Dymax Corporation, Precision Valve & Automation, Inc., Nordson Corporation, Henkel AG, Peters Group, and Shin-Etsu Chemical Co. Ltd.

RelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed