Global CNC Video Measuring Market Size, Share, Growth Analysis Report - Forecast 2034

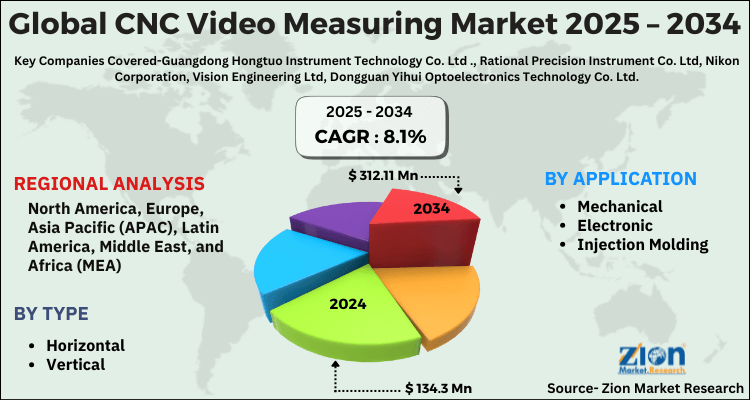

CNC Video Measuring Market By Type (Horizontal, Vertical), By Application (Mechanical, Electronic, Injection Molding, Others), and By Region: Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 134.3 Million | USD 312.11 Million | 8.1% | 2024 |

CNC Video Measuring Market: Industry Perspective

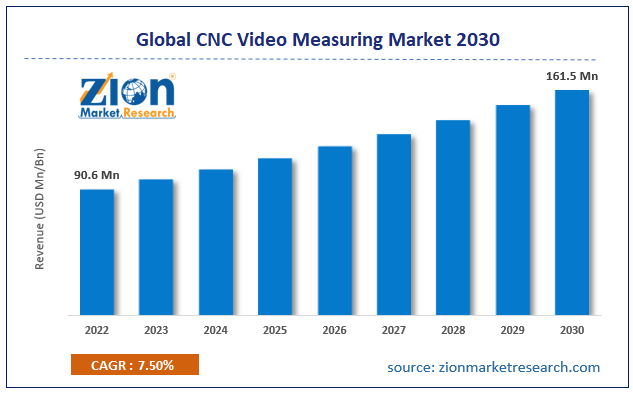

The global CNC video measuring market size was worth around USD 134.3 Million in 2024 and is predicted to grow to around USD 312.11 Million by 2034 with a compound annual growth rate (CAGR) of roughly 8.1% between 2025 and 2034. The report analyzes the global CNC video measuring market's drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the CNC video measuring industry.

CNC Video Measuring Market: Overview

A CNC video measuring machine is an automated measurement device that examines characteristics and estimates measurements of various products using a camera and computer software. It is extensively utilized in the industrial sector for dimensional analysis, reverse engineering, and quality control. The market is anticipated to develop significantly as a result of technological improvements, growing industry automation, and an increase in demand for precise and accurate measuring systems. The CNC video measuring industry is expected to develop even more as a result of the incorporation of machine learning and artificial intelligence algorithms with CNC video measuring machines. The machines will be able to assess dimensions, carry out intricate analyses, and interpret data due to these developments.

Key Insights

- As per the analysis shared by our research analyst, the global CNC video measuring market is estimated to grow annually at a CAGR of around 8.1% over the forecast period (2025-2034).

- Regarding revenue, the global CNC video measuring market size was valued at around USD 134.3 Million in 2024 and is projected to reach USD 312.11 Million by 2034.

- The CNC video measuring market is projected to grow at a significant rate due to increasing demand for high-precision quality control and assurance in various manufacturing industries, rising adoption of automation and smart manufacturing practices, and growing complexity and miniaturization of electronic and mechanical components.

- Based on Type, the Horizontal segment is expected to lead the global market.

- On the basis of Application, the Mechanical segment is growing at a high rate and will continue to dominate the global market.

- Based on region, Asia-Pacific is predicted to dominate the global market during the forecast period.

CNC Video Measuring Market: Dynamics

Key Growth Drivers:

The CNC video measuring market is propelled by increasing demand for high-precision dimensional inspection across automotive, aerospace, electronics, and medical device manufacturing where tighter tolerances and quality standards are critical. Advancements in imaging sensors, optics, and software — including 3D measurement capabilities and automation integration with CNC systems — improve throughput and measurement accuracy, encouraging adoption. Rising emphasis on reducing scrap and rework, along with Industry 4.0 initiatives that prioritize inline inspection and data-driven quality control, further accelerate market growth. Additionally, growing production complexity and miniaturization of components require non-contact, high-resolution metrology solutions, boosting demand for advanced CNC video measuring systems.

Restraints:

High upfront capital costs for advanced CNC video measuring equipment and the expense of integrating them into existing production lines can deter small and medium-sized manufacturers from investing. The need for skilled metrology and maintenance personnel to operate, calibrate, and interpret results limits rapid deployment in regions with talent shortages. Compatibility challenges with legacy manufacturing systems and variable part fixturing requirements increase implementation complexity and costs. Moreover, frequent calibration and stringent environmental control (temperature, vibration, lighting) required for accurate measurements can raise ongoing operational expenses and hinder wider adoption.

Opportunities:

Opportunities arise from growing adoption of automation and inline inspection in smart factories, where CNC video measuring systems can be integrated with robotics and MES for real-time quality feedback. Emerging markets that are scaling advanced manufacturing capacity present significant untapped demand, especially in electronics, medical devices, and precision machining. Development of more compact, cost-effective, and portable video metrology systems opens sales avenues to smaller shops and field-inspection use cases. Software-driven improvements — AI-assisted defect detection, cloud-based analytics, and digital twins — create new service and subscription revenue models and increase the value proposition of video measuring solutions.

Challenges:

Key challenges include maintaining measurement accuracy across diverse part geometries, materials, and surface finishes, which can complicate system setup and reduce first-pass yield for inspections. Rapid technological change demands continuous R&D investment from vendors to stay competitive, while short product life cycles strain return-on-investment calculations for buyers. Interoperability between different metrology systems, CAD/CAM software, and factory IT infrastructure remains a barrier to seamless data flow. Finally, convincing conservative manufacturers to shift from traditional contact metrology to optical CNC video systems requires clear demonstrations of reliability and long-term cost benefits.

CNC Video Measuring Market: Segmentation

The global CNC Video Measuring industry is segmented based on the type, application, and region. All the segments have been analyzed based on present and future trends and the market is estimated from 2025 to 2034.

Based on the type, the global market is bifurcated into horizontal and vertical. The horizontal type segment is expected to hold a significant CNC video measuring market share over the forecast period. Horizontal machining centers are more beneficial for intricate undercuts and mold cavity machining than vertical machining centers because they make it simpler to remove chips during workpiece processing. Large workpieces may be processed using horizontal machining centers because of their structural benefits. In short, horizontal machining centers can be used to manufacture workpieces that are too big or too complicated for vertical machining centers. Thereby, driving the market growth.

Based on the application, the global CNC video measuring industry is bifurcated into mechanical, electronic, injection molding, and others. The mechanical segment is expected to dominate the market during the forecast period. The precision of measurements in CNC video measuring systems relies heavily on the quality and precision of mechanical components such as linear guides, ball screws, and stages. High-precision mechanical components contribute to the accuracy and repeatability of measurements, ensuring reliable performance in various applications. Thereby, driving the market expansion.

The Regional, this segment includes the current and forecast demand for North America, Europe, Asia Pacific, Latin America,and the Middle East and Africa.

CNC Video Measuring Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | CNC Video Measuring Market |

| Market Size in 2024 | USD 134.3 Million |

| Market Forecast in 2034 | USD 312.11 Million |

| Growth Rate | CAGR of 8.1% |

| Number of Pages | 232 |

| Key Companies Covered | Guangdong Hongtuo Instrument Technology Co. Ltd ., Rational Precision Instrument Co. Ltd, Nikon Corporation, Vision Engineering Ltd, Dongguan Yihui Optoelectronics Technology Co. Ltd., Electronica Mechatronic Systems, Carlssoon Technologies (Malaysia) Sdn Bhd, Sahil Technocrats, Baker Gauges India Pvt. Ltd., Haida International Equipment Co. Ltd, and others. |

| Segments Covered | By Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2020 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

CNC Video Measuring Market: Regional Analysis

Asia Pacific is expected to capture a significant market share during the forecast period

The Asia Pacific is expected to capture a significant CNC video measuring market share during the forecast period. The market growth in the region is attributed to the growing end-use industries including automotive and aerospace. Video measuring systems with CNC (Computer Numerical Control) play an important role in the automobile sector by offering accurate and automated measurement solutions for different parts. Automotive components undergo comprehensive dimensional checks using CNC video measuring devices. To make sure that components fulfill design criteria, this involves measuring crucial measurements such as lengths, diameters, angles, and tolerances. Furthermore, for safety and effectiveness, brake parts like discs and calipers need to be measured precisely. Brake component measurements may be taken precisely using CNC video measuring systems, which can also spot deviations from requirements. Therefore, the growth in this industry positively impacted the market growth.

CNC Video Measuring Market: Competitive Analysis

The report provides a company market share analysis to give a broader overview of the key market players. In addition, the report also covers key strategic developments of the market, including acquisitions & mergers, new product launches, agreements, partnerships, collaborations & joint ventures, research & development, and regional expansion of major participants involved in the CNC video measuring market on a global and regional basis.

The global CNC Video Measuring market is dominated by players like:

- Guangdong Hongtuo Instrument Technology Co. Ltd .

- Rational Precision Instrument Co. Ltd

- Nikon Corporation

- Vision Engineering Ltd

- Dongguan Yihui Optoelectronics Technology Co. Ltd.

- Electronica Mechatronic Systems

- Carlssoon Technologies (Malaysia) Sdn Bhd

- Sahil Technocrats

- Baker Gauges India Pvt. Ltd.

- Haida International Equipment Co. Ltd.

The global CNC Video Measuring market is segmented as follows:

By Type

- Horizontal

- Vertical

By Application

- Mechanical

- Electronic

- Injection Molding

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

A CNC video measuring machine is an automated measurement device that examines characteristics and estimates measurements of various products using a camera and computer software. It is extensively utilized in the industrial sector for dimensional analysis, reverse engineering, and quality control.

The global CNC video measuring market is expected to grow due to rising demand for precision measurement in manufacturing, advancements in automation and Industry 4.0, increasing adoption in aerospace and automotive sectors, and the need for high-accuracy quality control solutions.

According to a study, the global CNC video measuring market size was worth around USD 134.3 Million in 2024 and is expected to reach USD 312.11 Million by 2034.

The global CNC video measuring market is expected to grow at a CAGR of 8.1% during the forecast period.

Asia-Pacific is expected to dominate the CNC video measuring market over the forecast period.

Leading players in the global CNC video measuring market include Guangdong Hongtuo Instrument Technology Co. Ltd ., Rational Precision Instrument Co. Ltd, Nikon Corporation, Vision Engineering Ltd, Dongguan Yihui Optoelectronics Technology Co. Ltd., Electronica Mechatronic Systems, Carlssoon Technologies (Malaysia) Sdn Bhd, Sahil Technocrats, Baker Gauges India Pvt. Ltd., Haida International Equipment Co. Ltd, among others.

The report explores crucial aspects of the CNC video measuring market, including a detailed discussion of existing growth factors and restraints, while also examining future growth opportunities and challenges that impact the market.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed