AC Screw Air Compressor Market Size, Share and Forecast 2034

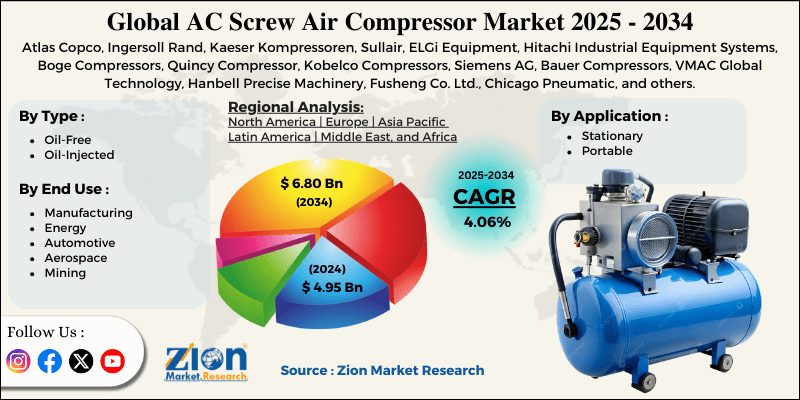

AC Screw Air Compressor Market By Type (Oil-Free, Oil-Injected), By Application (Stationary, Portable), By End-Use (Manufacturing, Energy, Automotive, Aerospace, Mining), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

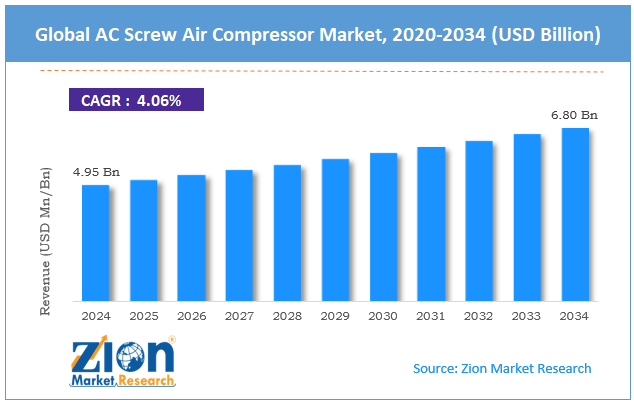

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 4.95 Billion | USD 6.80 Billion | 4.06% | 2024 |

AC Screw Air Compressor Industry Perspective:

The global AC screw air compressor market size was worth around USD 4.95 billion in 2024 and is predicted to grow to around USD 6.80 billion by 2034, with a compound annual growth rate (CAGR) of roughly 4.06% between 2025 and 2034.

AC Screw Air Compressor Market: Overview

AC screw air compressors are proficient, rotary-type compressors that utilize two intermeshing helical screws to compress air. These compressors offer consistent and continuous airflow, increasing their suitability for operations needing steady pressure. They are extensively used in commercial and industrial applications and are known for their low maintenance, quiet operation, and energy efficiency. The global AC screw air compressor market is likely to expand rapidly, driven by the growing global demand for industrial automation, increasing demand in the mining and oil and gas sectors, and the benefits of cost savings and energy efficiency. The growth in Industry 4.0 practices and automation across manufacturing industries is propelling the demand for efficient compressed air systems. AC screw compressors guarantee continuous power for pneumatic tools, automated lines, and robotic arms.

Moreover, screw compressors are broadly used for extraction, exploration, and refining activities. Their ability to perform in extreme environments and durability increase their suitability in these industries. For example, North American and Middle Eastern oil & gas projects are heavily deploying screw compressors. In addition, screw models deliver consistent results and consume less energy. As global energy consumption increases, companies are adopting screw compressors to reduce long-term operating costs. A majority of governments are also offering energy-efficient incentives to encourage their adoption.

Despite the growth, the global market is impeded by factors such as complex repair and maintenance needs and dependence on electrical supply. While these screws are durable, they need dedicated maintenance. Technical problems like oil leakage or rotor damage may hamper operations and invite high servicing costs. These compressors require a stable power source, which limits their use in underdeveloped or remote areas. In regions with unstable energy supply, hybrid or diesel models are highly preferred.

Nonetheless, the global AC screw air compressor industry stands to gain from a few key opportunities, like the adoption of VSD technology and the emergence of sustainable manufacturing. VSD screw compressors adjust motor speed depending on air demand, mainly saving power. Companies are highly investing in VSD models, generating a strong industry opportunity. Also, sustainability programs are encouraging industries to adopt eco-friendly machines. Screw compressors with high efficiency and low emissions comply well with ESG targets and green manufacturing trends.

Key Insights:

- As per the analysis shared by our research analyst, the global AC screw air compressor market is estimated to grow annually at a CAGR of around 4.06% over the forecast period (2025-2034)

- In terms of revenue, the global AC screw air compressor market size was valued at around USD 4.95 billion in 2024 and is projected to reach USD 6.80 billion by 2034.

- The AC screw air compressor market is projected to grow significantly owing to the growing demand from mining and oil & gas industries, growth in refrigeration and HVAC applications, and rising use in food and beverage processing.

- Based on type, the oil-injected segment is expected to lead the market, while the oil-free segment is expected to grow considerably.

- Based on application, the stationary segment is the dominating segment, while the portable segment is projected to witness sizeable revenue over the forecast period.

- Based on end-use, the manufacturing segment is expected to lead the market compared to the automotive segment.

- Based on region, the Asia Pacific is projected to dominate the global market during the estimated period, followed by Europe.

AC Screw Air Compressor Market: Growth Drivers

The rise of the pharmaceutical and food & beverage industries boosts market growth

The rising strictness in hygiene standards in the pharmaceutical and food and beverage sectors is fueling the demand for contamination-free and oil-free AC screw compressors, thus impacting the global AC screw air compressor market. These compressors promise dry, clean, and contaminant-free compressed air, vital for sensitive uses like food packaging and manufacturing.

The EU EMA and the United States FDA reinforced regulations on compressed air quality in pharma cleanrooms, resulting in a spike in demand for certified oil-free compressors. Companies like Quincy Compressor and Boge have introduced ISO 8573-1 Class 0 certified AC screw compressors to resolve this demand.

How developments in remote monitoring and compressor design fuel the AC screw air compressor market?

Advancements in compressor technology, such as IoT-driven monitoring systems, VSDs, and oil-free operation, are significantly improving the energy profile and functionality of AC screw compressors. VSD technology alone can reduce energy consumption by 35% during partial load operations, increasing its appeal among industries with unstable demand.

Atlas Copco introduced a smart compressor series embedded with the Elektronikon® Touch controller, allowing predictive maintenance and real-time energy tracking, in January 2025.

AC Screw Air Compressor Market: Restraints

Lack of skilled labor for maintenance and technical complexity negatively impacts market progress

Screw compressors, particularly those equipped with VSDs, IoT systems, and advanced diagnostics, require skilled operators and technicians to ensure optimal fault management and maintenance. The lack of trained personnel in many regions may result in poor performance, equipment failure, or frequent misuse. This concern is especially acute in the emerging countries, where industrial training programs are restricted.

Compressor OEMs in Southeast Asia and Latin America reported growing demand for service training programs as users struggle to manage high-technology models in 2025.

AC Screw Air Compressor Market: Opportunities

How does government support for industrial upgrades and infrastructure contribute to the growth of the AC screw air compressor market?

Governments across the globe are introducing programs to advance industrial infrastructure, mainly in water treatment, power generation, and manufacturing. AC screw compressors, capable of continuous operation and handling high loads, are widely utilized in public-private partnerships (PPP) and state-backed projects.

Made in China 2025, a Chinese initiative, promotes the advancement of manufacturing plants with energy-efficient equipment like screw compressors. In 2024, China's (MIIT) Ministry of Industry and Information Technology added energy-saving compressors to its subsidy list, aiding local players like Shanghai Hitachi and Hanbell to scale domestic deployments. These initiatives and efforts are fueling the growth of the global AC screw air compressor industry.

AC Screw Air Compressor Market: Challenges

How is increasing competition from low-cost and local manufacturers limiting the AC screw air compressor market growth?

The market is becoming saturated with low-cost AC screw compressors, mainly from Southeast Asian and Chinese manufacturers. While global brands emphasize innovation and premium quality, local companies offer economic models that attract budget-conscious buyers in the developing economies, posing increasing challenges for the premium brands to maintain pricing power.

A Frost & Sullivan 2025 report cited that more than 40% of screw compressors sold in APAC under $5,000 come from regional suppliers. These products usually bypass certifications or offer short-period warranties, increasing their appeal for small producers. This rising presence of budget-friendly options hinders the long-term competitiveness of established OEMs in low- and mid-end market domains.

AC Screw Air Compressor Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | AC Screw Air Compressor Market |

| Market Size in 2024 | USD 4.95 Billion |

| Market Forecast in 2034 | USD 6.80 Billion |

| Growth Rate | CAGR of 4.06% |

| Number of Pages | 213 |

| Key Companies Covered | Atlas Copco, Ingersoll Rand, Kaeser Kompressoren, Sullair, ELGi Equipment, Hitachi Industrial Equipment Systems, Boge Compressors, Quincy Compressor, Kobelco Compressors, Siemens AG, Bauer Compressors, VMAC Global Technology, Hanbell Precise Machinery, Fusheng Co. Ltd., Chicago Pneumatic, and others. |

| Segments Covered | By Type, By Application, By End Use, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

AC Screw Air Compressor Market: Segmentation

The global AC screw air compressor market is segmented based on product type, material type, end-user industry, and region.

Based on type, the global AC screw air compressor industry is divided into oil-free and oil-injected. The oil-injected compressors segment holds leadership in the worldwide market owing to their durability, higher efficiency, and cost-efficiency. They are extensively used in heavy-duty applications, such as the automotive sector, mining, and manufacturing, where a small amount of oil in compressed air is acceptable. Their ability to work uninterruptedly under high loads increases their preference in a majority of industrial setups.

Based on application, the global AC screw air compressor market is segmented into stationary and portable. The stationary AC screw air compressors segment dominates the worldwide market owing to their sustainability and high efficiency for continuous and heavy-duty industrial operations. These compressors are permanently deployed in automotive workshops, food processing units, manufacturing plants, and oil & gas facilities, where a continuous and stable compressed air supply is vital. Their ability to deliver consistent pressure with high energy efficiency and low maintenance offers them a competitive advantage over other types of compressors.

Based on end-use, the global market is segmented into manufacturing, energy, automotive, aerospace, and mining. The manufacturing sector captures a leading share in the global market. AC screw air compressors are vital for powering assembly lines, automation systems, and tools in industries like packaging, textiles, general industrial goods, and electronics. Their ability to deliver reliable and continuous compressed air makes them crucial in 24/7 production settings. As global manufacturing capacity expands, mainly in APAC, the demand for compressors continues to rise.

AC Screw Air Compressor Market: Regional Analysis

Why is Asia Pacific holding leadership in the worldwide AC screw air compressor market?

Asia Pacific is anticipated to retain its leading role in the global AC screw air compressor market as a result of speedy industrialization, rising adoption of energy-efficient solutions, and expanding electronics and automotive industries. Asia Pacific is experiencing substantial industrial expansion, mainly in Vietnam, Indonesia, and India. As per the Asian Development Bank, infrastructure investments in the region are anticipated to surpass USD 26 trillion by 2030. This rapid urbanization drives up demand for AC screw air compressors in utilities, construction, and manufacturing industries.

Furthermore, governments in the region are encouraging energy-efficient equipment to enhance industrial productivity and lessen carbon emissions. For example, India's Perform Achieve and Trade (PAT) scheme motivates industries to move to high-efficiency compressors. This pressure has fueled the sales of smart AC air compressors and VSD in the past few years.

Additionally, APAC is a leading hub for electronics and automotive production, with Japan, China, South Korea, and India leading exports. In 2024, more than 50% of global vehicle production came from Asia. These industries heavily depend on compressed air systems, fueling major investments in AC screw air compressors.

Europe ranks as the second-leading region in the global AC screw air compressor industry as a result of a robust industrial base in Central and Western Europe, emphasis on emission reduction, and smart factory integration. Europe holds a well-established industrial landscape, especially in Italy, Germany, France, and the UK. AC screw compressors are extensively used in robotics, precision manufacturing sectors, and machinery. Also, European regulations like the Energy Efficiency Directive and the EU Ecodesign Directive are forcing industries to adopt energy-efficient machines.

VSD screw compressors are gaining prominence due to their low power consumption. This regulatory pressure is a key propeller for eco-friendly and premium technologies. European industries are speedily using digital transformation and Industry 4.0. Manufacturers are actively investing in IoT-driven compressors with real-time monitoring features and predictive maintenance. Companies like Kaeser and Atlas Copco are forerunners in advancements in connected and smart screw compressor solutions.

AC Screw Air Compressor Market: Competitive Analysis

The leading players in the global AC screw air compressor market are:

- Atlas Copco

- Ingersoll Rand

- Kaeser Kompressoren

- Sullair

- ELGi Equipment

- Hitachi Industrial Equipment Systems

- Boge Compressors

- Quincy Compressor

- Kobelco Compressors

- Siemens AG

- Bauer Compressors

- VMAC Global Technology

- Hanbell Precise Machinery

- Fusheng Co. Ltd.

- Chicago Pneumatic

AC Screw Air Compressor Market: Key Market Trends

Growing adoption of Variable Speed Drive (VSD) compressors:

Industries are actively adopting VSD AC screw compressors to decrease operational costs and energy consumption. These models adjust motor speed depending on air demand, enhancing efficiency by nearly 35% over fixed-speed units. This trend complies with global carbon-reduction and energy-saving programs.

Augmented demand for oil-free compressors:

Stringent air quality and hygiene standards in food and beverage, pharmaceutical, and electronics are driving the demand for oil-free AC screw compressors. These systems eliminate the risk of contamination and are expected to progress at a CAGR of more than 7% by 2030, mainly in the developed regions.

The global AC screw air compressor market is segmented as follows:

By Type

- Oil-Free

- Oil-Injected

By Application

- Stationary

- Portable

By End Use

- Manufacturing

- Energy

- Automotive

- Aerospace

- Mining

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

AC screw air compressors are proficient, rotary-type compressors that utilize two intermeshing helical screws to compress air. These compressors offer consistent and continuous airflow, increasing their suitability for operations needing steady pressure. They are extensively used in commercial and industrial applications and are known for their low maintenance, quiet operation, and energy efficiency.

The global AC screw air compressor market is projected to grow due to expanding manufacturing activities in emerging economies, technological improvements in compressor systems, and demand for continuous and reliable compressor supply.

According to study, the global AC screw air compressor market size was worth around USD 4.95 billion in 2024 and is predicted to grow to around USD 6.80 billion by 2034.

The CAGR value of the AC screw air compressor market is expected to be around 4.06% during 2025-2034.

Asia Pacific is expected to lead the global AC screw air compressor market during the forecast period.

The key players profiled in the global AC screw air compressor market include Atlas Copco, Ingersoll Rand, Kaeser Kompressoren, Sullair, ELGi Equipment, Hitachi Industrial Equipment Systems, Boge Compressors, Quincy Compressor, Kobelco Compressors, Siemens AG, Bauer Compressors, VMAC Global Technology, Hanbell Precise Machinery, Fusheng Co., Ltd., and Chicago Pneumatic.

The AC screw air compressor market faces challenges from high installation costs and initial investment, which discourage medium and small enterprises. Moreover, stringent environmental regulations and rising energy consumption limit broader adoption.

Market trends are inclining toward oil-free, energy-efficient, and smart AC screw air compressors with IoT integration. Consumers increasingly prefer low-maintenance, compact models suited for automated and sustainable industrial operations.

Pricing trends in the AC screw air compressor market present a steady increase due to rising energy and raw material costs, alongside surging demand for advanced, energy-efficient models. Nonetheless, regional manufacturing and competitive pricing pressures are encouraging cost-optimized product variants.

The report examines key aspects of the AC screw air compressor market, including a detailed analysis of existing growth factors and restraints, as well as an examination of future growth opportunities and challenges that will impact the market.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed